Wire Rope Winding Drum | Grooved, Heavy-Duty, Custom Sizes

wire rope winding drum,winding wire rope on a drum is a key solution in the General equipment manufacturing industry, specifically within Manufacturing of lifting and transportation equipment and Manufacturing of components for lifting machinery. This article explores how Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- wire rope winding drum,winding wire rope on a drum Overview

- Benefits & Use Cases of wire rope winding drum,winding wire rope on a drum in Manufacturing of components for lifting machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in General equipment manufacturing industry

- Conclusion on wire rope winding drum,winding wire rope on a drum from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

wire rope winding drum,winding wire rope on a drum Overview

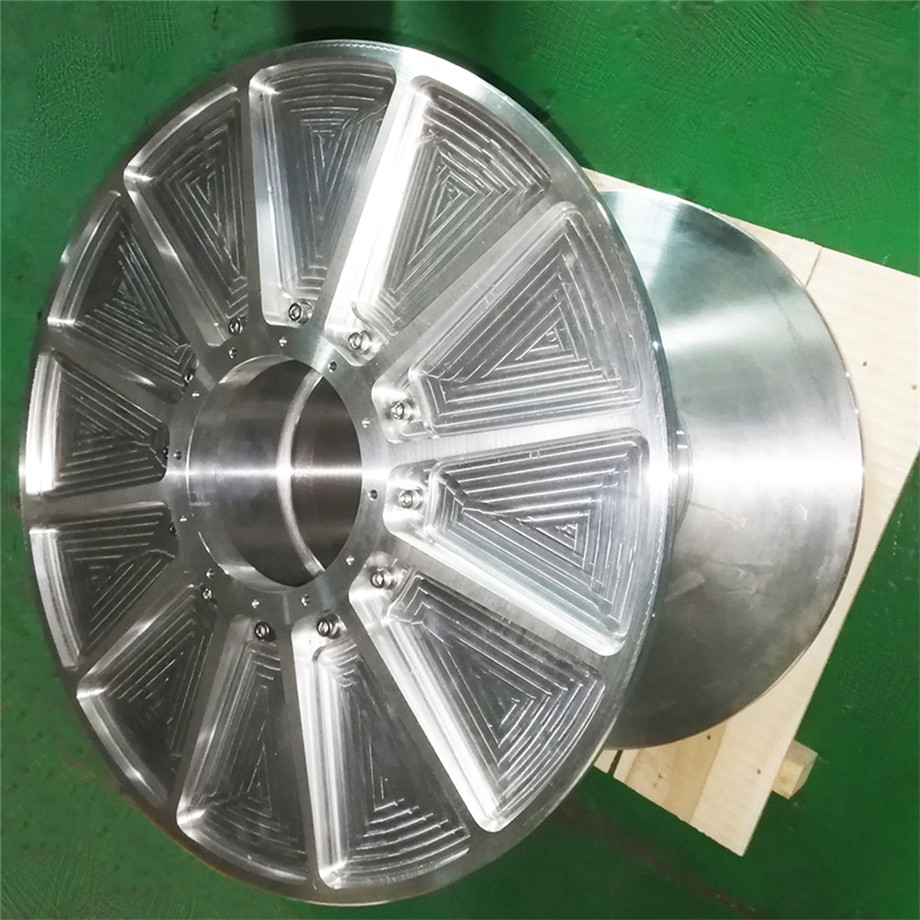

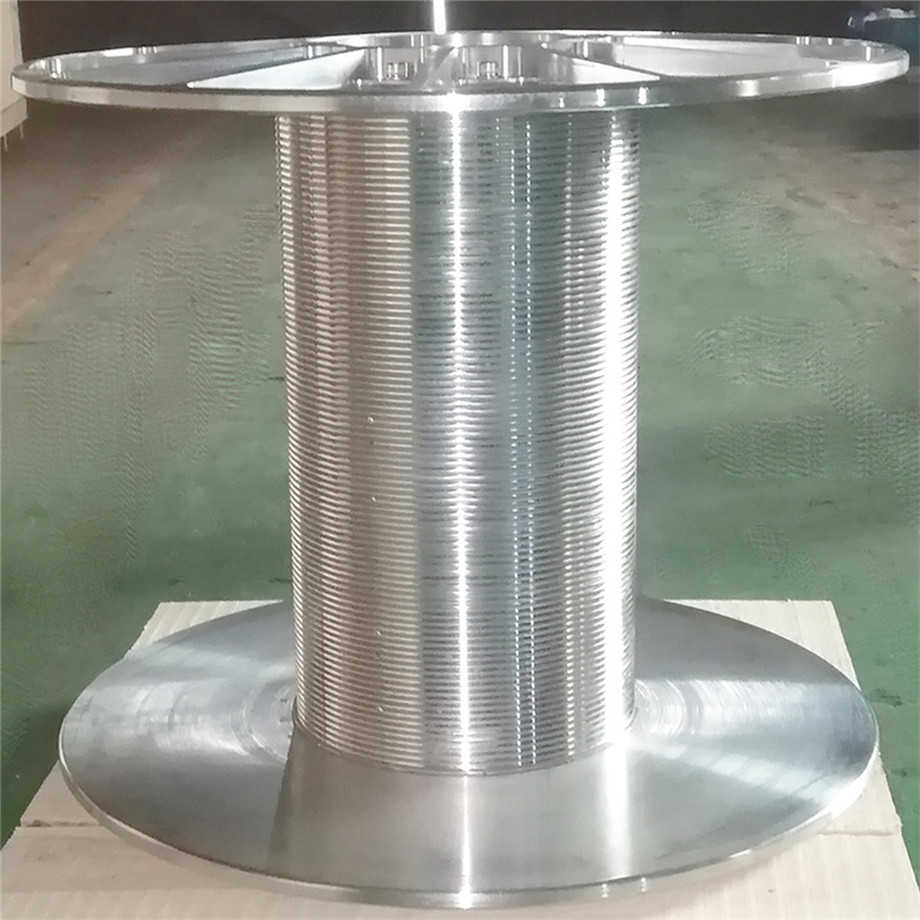

A wire rope winding drum is the core spooling component that stores, guides, and controls line pull for hoists, cranes, winches, and other lifting systems. For B2B decision makers operating in the Manufacturing of lifting and transportation equipment and the Manufacturing of components for lifting machinery, the drum’s groove geometry, material, and machining accuracy directly influence rope life, safety, and uptime. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. engineers aluminum-alloy drums with precision grooving to support multi-layer spooling while minimizing crushing, cross-overs, and bird-nesting when winding wire rope on a drum.

Built to customer specifications, these drums can be supplied as one-piece barrels, split drums, or replaceable grooved sleeves. Typical options include: optimized Lebus-style multi-layer grooves matched to rope diameter and lay; hard-anodized surfaces for wear and corrosion resistance; integral flanges and reinforcement ribs; dynamic balance; and NDT inspection. Aluminum alloy construction reduces mass versus traditional steel, enabling faster acceleration/deceleration and improved energy efficiency in mobile cranes and offshore winches. Whether for port gantry cranes, tower cranes, subsea AHC winches, or mining hoists, Junzhong’s wire rope winding drum,winding wire rope on a drum solutions are engineered to deliver repeatable, smooth spooling under demanding loads.

Benefits & Use Cases of wire rope winding drum,winding wire rope on a drum in Manufacturing of components for lifting machinery

In component manufacturing for lifting machinery, drums must maintain rope integrity over thousands of cycles. Junzhong’s aluminum-alloy grooved drums are designed for applications such as crane hoists, truck-mounted cranes, offshore and deck winches, drilling rigs, stage hoists, and specialized traction systems. The precise groove profile and pitch help maintain consistent fleet angles and tension distribution, reducing strand distortion and prolonging rope life when winding wire rope on a drum across multiple layers.

Key advantages include weight reduction for improved system dynamics, high corrosion resistance via anodizing for marine or chemical environments, and customizable groove patterns that align with specific rope constructions. Optional split-barrel and bolt-on sleeve designs enable rapid maintenance without replacing the entire drum. For OEMs, this translates into easier integration, lower assembly time, and predictable performance in the field. Backed by Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.’s application engineering, FAT support, and rope–drum matching expertise, customers gain a robust, low-risk path to optimizing multi-layer spooling and maximizing equipment availability.

Cost, Maintenance & User Experience

Total cost of ownership hinges on rope life, downtime, and energy consumption. By pairing precision grooving with aluminum-alloy construction, a Junzhong wire rope winding drum helps reduce wear on the rope, mitigates crush damage on lower layers, and lightens rotating mass—contributing to energy savings and smoother motion profiles. Over the equipment lifecycle, fewer rope replacements, shorter service stops, and improved operating efficiency support a compelling ROI for crane and winch OEMs and fleet operators.

Maintenance is straightforward: regularly inspect groove surfaces, verify flange condition, monitor rope lubrication and discard criteria (per applicable standards such as ISO-guided practices), and keep the drum clean from debris or abrasive media. Users in the Manufacturing of lifting and transportation equipment sector report stable multi-layer spooling, fewer crossovers, and consistent line pull from first to last wrap. When required, replaceable sleeves or split-drum configurations minimize downtime—allowing service teams to restore optimal spooling performance quickly without major disassembly.

Sustainability & Market Trends in General equipment manufacturing industry

Lightweighting, electrification, and circularity are reshaping lifting equipment design. Aluminum-alloy drums align with these trends: lower component mass can reduce energy use in mobile equipment and facilitate electrified powertrains, while aluminum’s recyclability supports end-of-life material recovery. Surface treatments like hard anodizing deliver durable protection without excessive maintenance chemicals, contributing to lower environmental impact over the drum’s service life.

Market demand is rising in ports, offshore wind, mining, and construction—sectors prioritizing uptime, safety, and lifecycle value. Digitalization also plays a role: pairing drums with load monitoring and rope inspection systems enables predictive maintenance and data-informed decision-making. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. invests in advanced machining, quality systems, and application engineering to meet evolving standards and customer ESG objectives. From responsible sourcing to efficient production and long-life designs, Junzhong positions its wire rope winding drum,winding wire rope on a drum portfolio for the next generation of sustainable lifting solutions.

Conclusion on wire rope winding drum,winding wire rope on a drum from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

For B2B decision makers in the General equipment manufacturing industry—particularly in Manufacturing of lifting and transportation equipment and Manufacturing of components for lifting machinery—Junzhong’s aluminum-alloy wire rope winding drum solutions deliver precision spooling, durability, and lifecycle value. Backed by engineering support and configurable designs, Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. is a trusted partner for mission-critical lifting applications.

Contact us: email: lbswinch@lebus.com.cn

Visit our website: https://www.lbswinch.com

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025