Double Drum Electric Winch – Heavy-Duty, Synchronized Pulling

Fishing Net Drum Winch: What Matters in a Real-World Double-Drum Setup

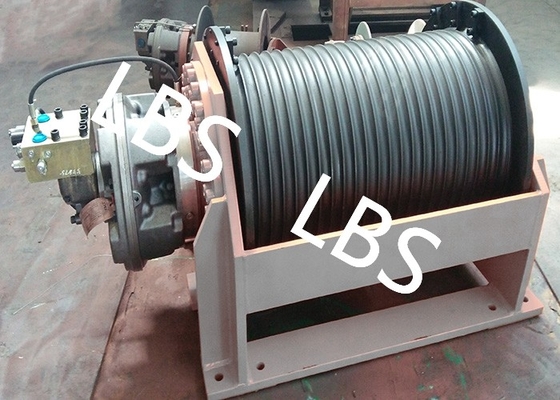

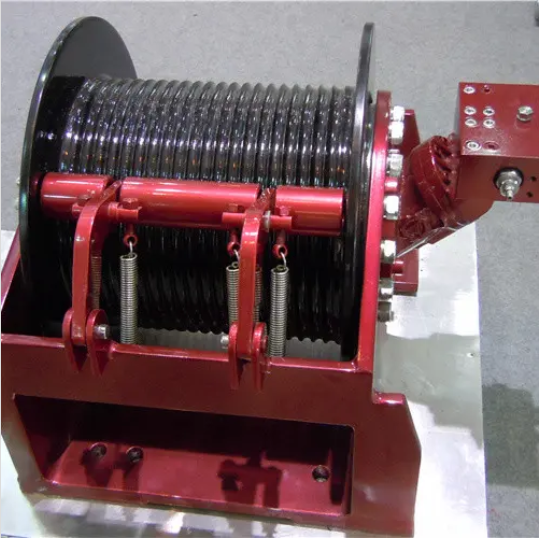

If you handle nets, mooring lines, or survey cables for a living, you already know: the heart of the deck is your double drum electric winch. The LBS grooved system—honestly a clever bit of engineering—keeps the spooling disciplined, layer after layer, so you don’t spend nights fixing bitten rope. I’ve seen crews go from grumbling to grinning in one tide shift.

Industry snapshot and what buyers ask

Trend-wise, we’re seeing compact DC options (yes, 12V on working decks) paired with smart tension feedback and sealed drives for salt fog. Many customers say they want predictable line lay and fewer bird’s nests—no surprise there. It seems that double drum electric winch packages with LBS grooving are carving out market share because the rope lasts longer and the pull stays steady under shock loads.

Quick specs (real-world values may vary)

| Model | Fishing Net Drum Winch Electric Double Drum Winch 12V Drum Winch Motor |

| Rated line pull | ≈ 30–80 kN (custom) |

| Rope diameter | ≈ 10–22 mm |

| Line speed | 0–30 m/min, VFD optional |

| Motor voltage | 12V DC (also 24V, 380–460V AC) |

| Protection | IP55–IP66 |

| Grooved drum | LBS system, anti-bite spooling |

| Finish | Marine epoxy; hot-dip galvanizing on request |

Where it works best

- Fishing: net shooting/hauling, purse seine operations.

- Ports and aquaculture: mooring assistance, cage handling.

- Survey and geotech: cable deployment, tow winch duties.

To be honest, a double drum electric winch saves space when you need two lines ready—no extra gearbox gymnastics.

Build and test flow (how it’s actually made)

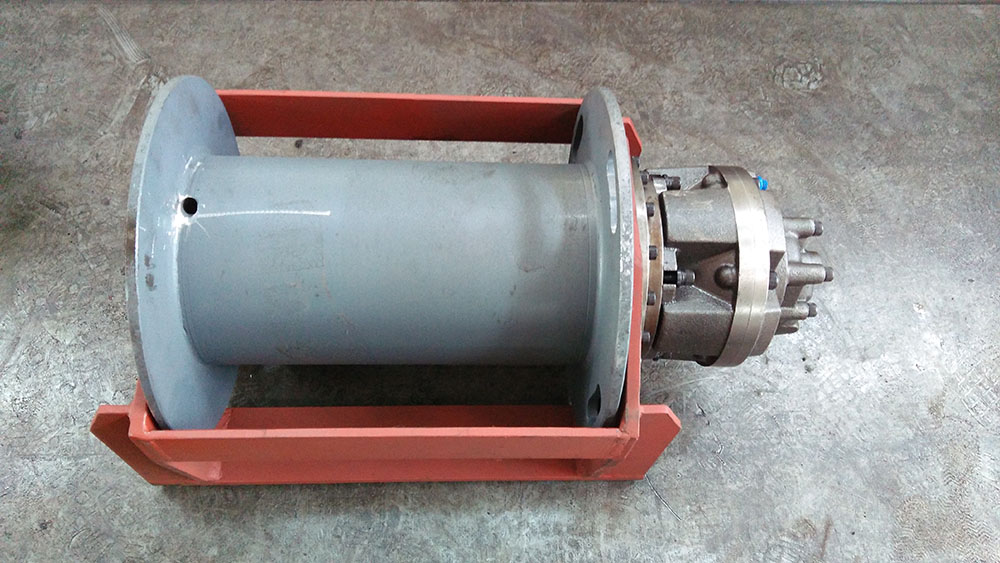

Materials: S355 steel drum shells, 42CrMo shafts, marine-sealed bearings, and tinned copper wiring. Methods include CNC-machined LBS grooves, stress-relieved weldments, epoxy primer + polyurethane topcoat. Tests: 125% overload run, brake holding ≥ 1.5× rated load, insulation and IP checks, salt-spray to ASTM B117 (selected parts). Rope management follows ISO 4309 guidelines, with discard criteria by broken wire count/lay length.

Service life: around 10–15 years with scheduled lubrication; rope life depends on cycles and fleet angle, of course.

Vendor comparison (snapshot)

| Feature | LBS Winch | Vendor A | Vendor B |

|---|---|---|---|

| Grooved drum tech | LBS anti-bite | Standard spiral | Spiral + sleeves |

| Cert support | EN 14492-1, CE, DNV/ABS on request | CE | CE, partial class options |

| MOQ / supply | MOQ 100 pcs; 10k pcs/month | Small batches | Medium |

| Customization | Voltage, groove, sensors | Limited | Moderate |

Customization and add-ons

Options include 12/24V DC or 3-phase AC motors, stainless drums for harsh chem environments, load pins, encoder feedback, radio remote, and PLC interlocks. A double drum electric winch with differential control helps when one net wing needs a touch more tension—seen it save a catch more than once.

Case notes and test data

- Trawler retrofit: 20% faster net retrieval; rope damage incidents down from weekly to “rare.”

- Barge survey: line speed hold within ±5% under gusting winds.

- Noise on deck: ≈ 72 dB(A) at 1 m (no-load), around 78 dB(A) at 75% load.

Compliance pointers: EN 14492-1, ISO 4309 for rope care, and class approvals (DNV, ABS) on project basis. Origin: NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China. Price ranges FOB (US $0.5–9,999 / piece) vary—speak to sales for the exact duty cycle and drum geometry.

Customer feedback: “Smooth spooling—even when the swell hits.” Another captain told me, “We stopped fighting the rope. That’s the win.” That’s really the point of a double drum electric winch, isn’t it?

References

- EN 14492-1: Power driven winches and hoists – Safety.

- ISO 4309: Wire ropes – Care, maintenance, inspection and discard.

- DNVGL-ST-0378: Offshore and platform lifting appliances.

- ABS Guide for Lifting Appliances, latest edition.

- ASTM B117: Standard Practice for Operating Salt Spray (Fog) Apparatus.

- IEC 60529: Degrees of protection (IP Code).

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025