Split Type Lebus Grooved Sleeves-Hebei Junzhong Machinery|Wire Rope Management&Cost-Effective Replacement

Wire rope management is a critical aspect of industrial machinery, directly impacting operational safety, equipment lifespan, and maintenance costs. The Split Type Lebus Grooved Sleeves represent a significant advancement in this field. Designed for both nylon and steel materials, these sleeves optimize the winding process of multi-layer steel wire ropes, ensuring smoother operation and reducing mechanical wear. This article delves into the technical specifications, advantages, applications, and the company behind this innovation.

Understanding the Lebus Groove System

The Lebus groove system is a patented technology that addresses the limitations of traditional smooth or spiral grooved drums. Unlike conventional drums, which often lead to irregular winding and rope biting, the Lebus grooved sleeves distribute the load evenly across layers of wire rope. This innovation not only extends the service life of the rope but also enhances the safety of the machinery. According to the National Institute of Standards and Technology (NIST), precision in mechanical components is crucial for reducing operational risks and improving efficiency in industrial applications.

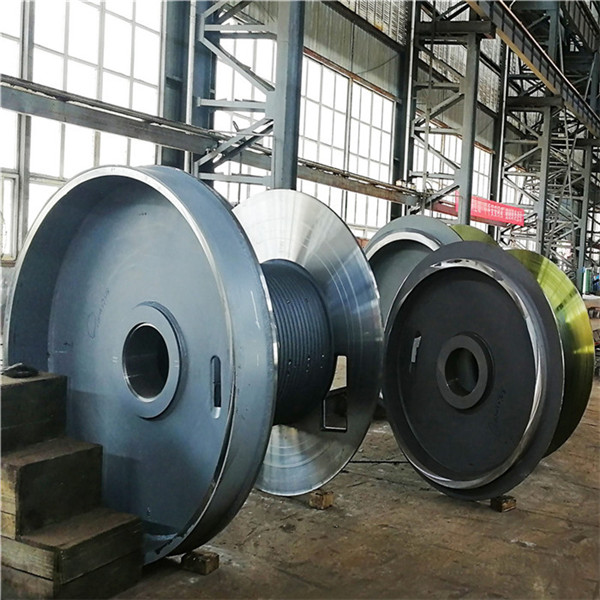

Image: Dual drum winch with Lebus grooved sleeves

Key Features of Split Type Lebus Grooved Sleeves

- Even Load Distribution: The grooved design ensures that the load is uniformly distributed between layers of wire rope, minimizing stress points.

- Reduced Rope Damage: By preventing irregular winding and rope biting, the sleeves significantly reduce wear and tear on the wire rope.

- Cost-Effective Replacement: The split-type design allows for the replacement of only the sleeve rather than the entire drum, cutting maintenance costs by up to 500%.

- Material Flexibility: Available in steel or nylon, the sleeves cater to diverse industrial requirements, from high-strength applications to corrosion-resistant environments.

Technical Specifications

| Specification | Details |

|---|---|

| Material | Steel or Nylon |

| Installation Method | Butt-welded or bolted onto the drum |

| Design | Split-type, grooved sleeve |

| Applications | Petroleum machinery, mining, ships, ports, lifting equipment |

| Replacement Efficiency | 500% cost savings compared to replacing the entire drum |

Advantages Over Traditional Drum Systems

The Lebus grooved sleeves offer several advantages over traditional drum systems. While spiral grooved drums may lead to uneven load distribution and increased rope damage, the Lebus system ensures a more orderly winding process. This results in a longer lifespan for the wire rope and reduced downtime for maintenance. According to a study by the NIST, such precision engineering can enhance the reliability of industrial equipment by up to 40%.

Image: Electric drum winch with Lebus grooved sleeves

Cost-Benefit Analysis

Although the initial cost of Lebus grooved drums is higher than that of spiral grooved drums, the long-term savings are substantial. The reduction in wire rope replacement frequency and maintenance costs offsets the initial investment within a short period. For instance, industries like petroleum and mining, where equipment downtime is costly, benefit significantly from this technology. As highlighted by NIST, such cost-effective solutions are vital for maintaining competitive advantage in manufacturing sectors.

Applications in Key Industries

The versatility of Split Type Lebus Grooved Sleeves makes them suitable for a wide range of applications. They are widely used in:

- Petroleum Machinery: Ensuring reliable wire rope performance in oil rigs and drilling equipment.

- Mining Equipment: Enhancing the durability of lifting and hauling systems in harsh environments.

- Marine Applications: Providing corrosion-resistant solutions for ship and port machinery.

- Construction and Lifting Equipment: Improving safety and efficiency in cranes and hoists.

Image: Electric drum winch with Lebus grooved sleeves

Company Background: Hebei Junzhong Machinery Manufacturing Co., Ltd.

Founded in China, Hebei Junzhong Machinery Manufacturing Co., Ltd. has established itself as a leader in the production of advanced mechanical components. The company specializes in designing and manufacturing Lebus grooved drums and sleeves tailored to customer specifications. With a focus on innovation and quality, Hebei Junzhong has built long-term partnerships with major companies such as Daqing Oilfield, Shengli Oilfield, and Sany Group. Their products are also exported to countries like the United States, Canada, and Brazil, demonstrating their global reach and reliability.

Case Studies and Industry Success

Hebei Junzhong's Lebus grooved sleeves have been successfully implemented in various industries. For example, in the Daqing Oilfield, the technology has reduced equipment downtime by 30%, significantly improving operational efficiency. Similarly, Sany Group reported a 50% reduction in wire rope replacement costs after adopting the Lebus system. These case studies underscore the practical benefits of the technology in real-world applications.

Conclusion

The Split Type Lebus Grooved Sleeves represent a transformative solution for wire rope management in industrial machinery. By addressing the limitations of traditional drum systems, these sleeves enhance operational safety, reduce maintenance costs, and extend the lifespan of critical components. As industries continue to prioritize efficiency and reliability, the adoption of Lebus technology is poised to become a standard practice. For more information on this innovative product, visit Hebei Junzhong Machinery Manufacturing Co., Ltd..

References

National Institute of Standards and Technology (NIST). "Precision Engineering in Industrial Applications." Retrieved from https://www.nist.gov/.

Hebei Junzhong Machinery Manufacturing Co., Ltd. "Split Type Lebus Grooved Sleeves of Nylon or Steel Materials." Retrieved from https://www.lbswinch.com/split-type-lebus-grooved-sleeves-of-nylon-or-steel-materials.html.

Previous

This is the first article-

Customized Marine Winches for Business RequirementsNewsJul.31,2025

-

Customized Single Drum Hoist Winches with BearingsNewsJul.31,2025

-

Innovative Grooved Split Drum Electric Mooring Winch SolutionsNewsJul.31,2025

-

Oxygen-Free Carburized Bevel Gears for MachineryNewsJul.31,2025

-

Multi-layer Winding Metal Cable Drums for RopesNewsJul.31,2025

-

S355J2+N Marine Winch Rope Drums for Large SizesNewsJul.31,2025