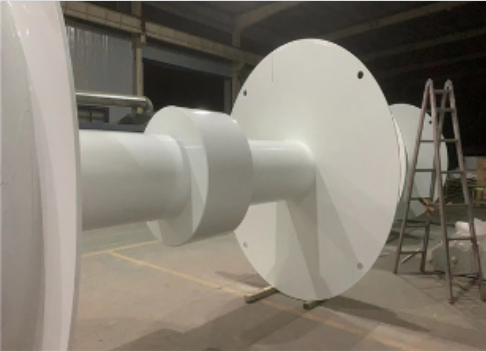

S355J2+N Marine Winch Rope Drums for Large Sizes

The marine and heavy lifting industries demand rope drums that can withstand extreme conditions while ensuring smooth operation and longevity. S355J2+N Marine Winch Rope Drums are engineered for high-performance applications, offering superior durability and efficiency. Designed for large-scale operations, these rope drums are ideal for marine winches, offshore platforms, and heavy-duty lifting systems.

Key Innovations of S355J2+N Marine Winch Rope Drums

- High-Strength Material: Made from S355J2+N steel, these rope drumsprovide exceptional resistance to corrosion and mechanical stress, making them suitable for harsh marine environments.

· Advanced Groove Technology: The double fold line wire rope groove ensures smooth rope winding, minimizing wear and tear on drum drag ropes. This specialized design maintains optimal rope alignment throughout operation.

· Modular Construction: The Lebus-built configuration combines a welded plain drum with grooved sleeves, enabling cost-effective maintenance through selective component replacement.

· Custom Engineering: Available in capacities from 100–10,000 meters with rope diameters of 3–500mm, these drums of rope can be precisely configured to application requirements.

Typical Applications of Marine Winch Rope Drums

- Offshore Anchor Handling: Provides reliable drum drag ropesmanagement during deepwater operations

· Dynamic Positioning Systems: Ensures controlled payout for vessel station-keeping

· Heavy Load Transfers: Supports high-capacity lifting operations with consistent performance

· Tugboat Towing Systems: Delivers durable operation in high-stress marine environments

Why Choose S355J2+N Marine Winch Rope Drums?

- Enhanced Rope Life: Optimized groove geometry reduces wear on drum drag ropes

· Reduced Maintenance Costs: Modular design simplifies component replacement

· Precision Manufacturing: CNC-machined to exacting tolerances for reliable performance

· Industry Compliance: Meets CCS/ABS certification standards for marine applications

Installation Guidelines for Rope Drums

- Alignment Verification: Ensure proper orientation between drum of ropeand drive system

· Pre-Operation Lubrication: Apply marine-grade lubricant to groove surfaces

· Initial Load Testing: Verify system performance with gradual load increases

· Periodic Inspection: Monitor groove condition and rope alignment

FAQs: Technical Specifications of Marine Winch Rope Drums

-

What are the material advantages of S355J2+N steel for rope drums in saltwater environments?

The alloy composition provides superior corrosion resistance and mechanical strength needed for prolonged marine exposure.

-

How does the Lebus design improve drum drag ropes performance?

The specialized groove profile maintains proper rope spacing and reduces crossover friction during operation.

-

What customization options exist for drums of rope dimensions?

Both diameter and length can be engineered to specific requirements, with rope capacities up to 10,000 meters. -

What quality certifications apply to these rope drums?

Products meet CCS and ABS standards for marine lifting equipment.

-

How does the drum of rope design accommodate different winding directions?

Units can be configured for either left or right rope entry based on winch system requirements.

Engineered for demanding marine applications, S355J2+N winch rope drums combine advanced materials with precision engineering. Their robust construction and customizable features make them ideal solutions for heavy-load handling operations where reliability and longevity are paramount. The innovative groove design and modular architecture deliver both performance advantages and maintenance benefits throughout the product lifecycle.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025