Precision Bevel Gear Sets for Sale - Durable & Reliable

The Crucial Role of Bevel Gear Sets in Modern Industrial Applications

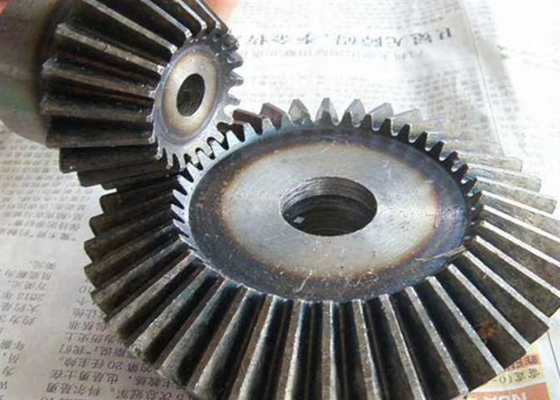

In the realm of mechanical power transmission, the choice of components directly impacts system efficiency, longevity, and reliability. Among these, the bevel gear set for sale stands out as a critical element for transmitting power between intersecting shafts, typically at a 90-degree angle. These gears are indispensable in a vast array of industries, from heavy machinery and automotive systems to precision robotics and aerospace. The global industrial gear market, valued at over $20 billion in 2023, continues to grow, driven by automation and infrastructure development, highlighting the persistent demand for high-quality, durable gear solutions designed to withstand rigorous operational demands and ensure continuous performance.

The demand for robust and precise bevel gears for sale has never been higher, fueled by technological advancements requiring more compact, efficient, and resilient transmission solutions. Emerging trends indicate a strong move towards higher power densities, reduced noise levels, and enhanced resistance to extreme operating conditions, including corrosive environments and high temperatures. This evolution necessitates materials with superior mechanical properties and advanced manufacturing techniques, such as oxygen-free carburizing, which significantly enhances the surface hardness and fatigue strength of the gears. Selecting the right bevel gear set for sale is not merely a purchase; it's an investment in the long-term operational integrity and productivity of complex machinery, leading to substantial cost savings from reduced downtime and maintenance.

Deep Dive into Bevel Gear Manufacturing Process and Superiority

From Raw Material to Precision Component: The Manufacturing Journey

The production of a high-performance bevel gear set for sale is a multi-stage, intricate process demanding metallurgical expertise and precision engineering. It typically begins with the selection of high-grade alloy steels, such as 20CrMnTi or 42CrMo, chosen for their excellent hardenability and core strength. The journey starts with material preparation, often involving forging to refine the grain structure and enhance mechanical properties, which is crucial for the gear's ultimate durability. This is followed by rough machining, which shapes the gear blank closer to its final dimensions, laying the groundwork for subsequent precision operations.

The core of the manufacturing process for a superior bevel gear lies in its heat treatment. Oxygen-free carburizing is a critical step for our Oxygen Free Carburizing Spur Bevel Gear For Transmission Machinery. This advanced thermal process involves heating the gear in a controlled atmosphere rich in carbon, allowing carbon atoms to diffuse into the surface, creating a hard, wear-resistant case (e.g., HRC 58-62) while maintaining a tough, ductile core. This technique drastically improves surface hardness and fatigue strength, significantly extending the gear's service life, especially under demanding loads and cyclic stresses common in industrial applications. Post-carburizing, the gears undergo precise quenching and tempering to achieve the desired microstructure and relieve internal stresses, ensuring optimal performance and resistance to cracking.

After heat treatment, precision finishing operations, including CNC grinding or honing, are performed to achieve the exact tooth profile, lead, and pitch required for minimal backlash, quiet operation, and optimal power transfer. Adherence to strict inspection standards, such as ISO 1328 for gear accuracy or AGMA 2015 for gear classification, ensures that each bevel gear meets stringent quality requirements. Non-destructive testing methods like magnetic particle inspection and ultrasonic testing are also employed to detect any subsurface imperfections. This meticulous approach guarantees a product with exceptional durability, minimal energy loss, and superior resistance to wear and corrosion, making it ideal for industries like petrochemical, metallurgy, and water treatment where equipment reliability is paramount. The average service life of our carburized gears often exceeds 50,000 operational hours under rated conditions, demonstrating tangible long-term value and reduced total cost of ownership.

Technical Specifications and Performance Metrics

When evaluating a bevel gear set for sale, technical specifications are key indicators of performance and suitability. Parameters such as module (tooth size), number of teeth, helix angle (for spiral bevels), pressure angle, and gear ratio dictate how the gear set will perform in a given application. The material's grade, heat treatment type, and surface hardness are crucial for load-carrying capacity and wear resistance. Below is a representative table of key parameters for high-performance bevel gears, providing a benchmark for prospective buyers seeking robust and reliable transmission solutions for their industrial needs.

Our Oxygen Free Carburizing Spur Bevel Gear is engineered to excel in scenarios demanding high torque transmission, minimal noise, and extended operational life. This makes them particularly well-suited for applications where efficiency translates directly to significant energy savings and reduced environmental impact. For instance, in large-scale pumping stations or conveyor systems, even a marginal improvement in gear efficiency can lead to substantial reductions in energy consumption over time, contributing to both economic and ecological benefits by optimizing power usage and minimizing waste.

Versatile Applications and Real-World Impact

Driving Industries Forward with Reliable Bevel Gears

The adaptability and robust nature of a quality bevel gear set for sale mean they are implemented across a broad spectrum of industries, powering critical operations worldwide. In the petrochemical sector, they are found in pumps, agitators, and mixers where corrosion resistance and long-term reliability in harsh chemical environments are non-negotiable. For metallurgy, these gears are essential in rolling mills, cranes, and material handling systems, enduring immense loads and shock. In water treatment and supply, they drive large valves, filtration systems, and pumps, often operating continuously under varying conditions, showcasing their versatility and reliability under pressure.

Beyond these core sectors, bevel gears for sale are integral to the mining industry for crushers and conveyors, in construction for excavators and heavy vehicles, and within the marine industry for propulsion and steering systems. Our product, the Oxygen Free Carburizing Spur Bevel Gear, has successfully been integrated into various high-stakes applications. For example, a major steel producer adopted our gears for their hot rolling mill, reporting a 15% reduction in unplanned downtime due to gear failure over a three-year period, attributing the improvement to the superior wear resistance and consistent quality provided. This direct feedback underscores the tangible operational benefits of investing in high-end bevel gear solutions.

Manufacturer Comparison and Custom Solutions

Choosing the Right Partner for Your Bevel Gear Needs

When sourcing a bevel gear set for sale, comparing manufacturers goes beyond just price. Key differentiators include their adherence to international quality standards (e.g., ISO 9001:2015 certification), their metallurgical expertise, capacity for customization, and post-sales support. While some manufacturers offer standard off-the-shelf solutions, true value often comes from partners who can provide tailored designs to meet specific load, speed, or environmental challenges. Our company has over 15 years of dedicated experience in precision gear manufacturing, holding multiple industry certifications and maintaining state-of-the-art testing facilities, ensuring both reliability and adaptability.

Our custom solution capabilities for bevel gears for sale encompass various aspects, including material selection, tooth geometry optimization (e.g., spiral vs. straight bevels, face width, helix angle), specific heat treatment profiles, and surface finishes tailored for particular lubrication regimes or extreme environments. We collaborate closely with clients during the design phase, leveraging advanced simulation software (e.g., FEA for stress analysis) to ensure the optimal gear configuration for their unique applications. This bespoke approach minimizes risks, enhances performance, and maximizes the return on investment for complex industrial machinery, providing a competitive edge in demanding sectors.

Our commitment to quality is reinforced by our comprehensive testing protocols, including CMM (Coordinate Measuring Machine) inspections for dimensional accuracy, metallurgical analysis for material integrity, and noise/vibration analysis to ensure smooth operation. We provide detailed test reports and certifications with every order, ensuring full transparency and compliance with global standards. This robust quality assurance process provides unparalleled trustworthiness, assuring our clients that every bevel gear delivered meets the highest standards of engineering excellence and performance.

Trustworthiness: FAQ, Delivery, and Warranty

Frequently Asked Questions (FAQ)

-

Q: What is the typical lead time for a custom bevel gear set for sale?

A: Lead times vary based on complexity and order volume. For standard configurations, expect 4-6 weeks. Custom designs typically range from 8-12 weeks, with expedited options available upon request to meet urgent project deadlines. We maintain clear communication throughout the production schedule to keep you informed.

-

Q: How do you ensure the quality and accuracy of your bevel gears?

A: Our quality assurance includes material certification from reputable suppliers, rigorous in-process inspections at every stage, comprehensive final testing (CMM for dimensions, hardness testing, surface finish analysis, runout checks), and strict compliance with ISO 9001 and AGMA standards. Each product undergoes rigorous checks before dispatch to guarantee peak performance.

-

Q: What warranty do you offer on your bevel gear sets?

A: We provide a standard 12-month warranty from the date of installation or 18 months from delivery, whichever comes first, against manufacturing defects. Extended warranty options are available for specific projects or long-term operational needs, offering additional peace of mind.

-

Q: Can your gears operate in corrosive or high-temperature environments?

A: Yes, our Oxygen Free Carburizing process enhances corrosion resistance, and specific material grades can be selected for high-temperature applications up to 300°C without significant loss of hardness. We can advise on suitable solutions based on your specific operational environment and performance requirements, ensuring optimal material selection and treatment.

Commitment to Seamless Delivery and Support

Our logistics team works diligently to ensure timely and secure delivery of your bevel gear set for sale, whether domestically or internationally. We partner with reliable shipping providers and utilize robust packaging to protect components during transit, minimizing any risk of damage. Beyond delivery, our dedicated customer support team is available for technical assistance, troubleshooting, and spare parts inquiries, ensuring continuous operational efficiency for your machinery. Our commitment extends far beyond the point of sale, providing peace of mind and building long-term partnerships founded on reliability and mutual success.

Authoritative References

- American Gear Manufacturers Association (AGMA) standards on gearing, including AGMA 2015-1A01: "Accuracy Classification System - Tangential Measurement Tolerance for Cylindrical Gears."

- International Organization for Standardization (ISO) 1328-1: "Cylindrical gears - ISO system of accuracy - Part 1: Definitions and allowable values of deviations relevant to corresponding flanks."

- ASM Handbook, Vol 4: "Heat Treating," discussing the principles and applications of carburizing and other thermochemical treatments for steel gears.

- Analysis of Power Transmission Systems in Heavy Industrial Machinery: Journal of Mechanical Engineering Science.

- Recent Advancements in Gear Material Science for Enhanced Durability and Efficiency: International Journal of Materials Research.

Previous

This is the first article-

Customized Marine Winches for Business RequirementsNewsJul.31,2025

-

Customized Single Drum Hoist Winches with BearingsNewsJul.31,2025

-

Innovative Grooved Split Drum Electric Mooring Winch SolutionsNewsJul.31,2025

-

Oxygen-Free Carburized Bevel Gears for MachineryNewsJul.31,2025

-

Multi-layer Winding Metal Cable Drums for RopesNewsJul.31,2025

-

S355J2+N Marine Winch Rope Drums for Large SizesNewsJul.31,2025