Powerful 12V Electric Winches for Off-Road & Marine Use

In the vast landscape of industrial and recreational lifting solutions, the electric winch 12v stands as a testament to portable power and versatile utility. From off-road recovery to marine anchoring and construction site assistance, these robust devices have become indispensable tools. This comprehensive guide delves deep into the world of electric winches, exploring their core technologies, diverse applications, and the critical distinctions between various power configurations like electric winch 12v, 100 lb electric winch 12v, and 110 volt electric winch. We will navigate industry trends, dissect technical specifications, examine manufacturing excellence, and present a holistic view for anyone seeking reliable hoisting and pulling solutions.

Industry Trends & Market Dynamics of Electric Winches

The global market for winches, including specialized electric winch 12v and 110 volt electric winch units, has witnessed steady growth driven by increasing demand from various sectors. According to a 2023 market analysis by Grand View Research, the global winches market size was valued at USD 1.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030. Key drivers include expanding automotive and off-road vehicle industries, burgeoning marine and aquaculture sectors, and continuous infrastructure development. There's a noticeable shift towards more compact, energy-efficient, and intelligent winch systems incorporating features like wireless remote control, automatic load sensing, and advanced braking mechanisms. The adoption of permanent magnet motors in DC winches is also gaining traction for their efficiency and power density.

Sustainability is another growing trend, with manufacturers focusing on materials that offer enhanced durability and corrosion resistance, reducing the need for frequent replacements. The demand for specialized units like the 100 lb electric winch 12v for light-duty applications, alongside heavy-duty industrial winches, reflects the diverse needs of the market.

Technical Parameters and Specifications: Understanding Your Winch

Selecting the right winch, whether it's a electric winch 12v or a 110 volt electric winch, hinges on understanding its technical specifications. These parameters dictate performance, safety, and suitability for specific tasks.

Key Technical Parameters

- Rated Line Pull (Lbs/Kg): The maximum weight the winch can pull on the first layer of rope. For a 100 lb electric winch 12v, this indicates its maximum pulling capacity, typically used for lighter tasks.

- Motor Type & Power (HP/KW): DC (12V/24V) motors are common for portable units, while AC (110V/220V/380V) motors power industrial models. Motor power directly impacts pulling speed and capacity.

- Gear Ratio: Determines the speed and torque. A higher ratio means slower speed but greater pulling power.

- Rope Type & Diameter: Steel wire rope or synthetic rope (e.g., Dyneema). Synthetic ropes are lighter and safer but require specific fairleads. Diameter affects breaking strength.

- Drum Capacity: The maximum length of rope the drum can hold.

- Braking System: Essential for safety, preventing load slippage. Common types include automatic mechanical brakes and dynamic brakes.

- Control System: Wired remote, wireless remote, or integrated control panel.

- IP Rating: Ingress Protection rating indicates resistance to dust and water. Crucial for marine or outdoor applications.

Comparative Table: Electric Winch 12V vs. 110 Volt Electric Winch

To highlight the differences and strengths of various electric winch types, here's a comparative table of typical parameters you might find for an electric winch 12v versus a 110 volt electric winch. This data is compiled from general industry specifications and commonly available models.

| Parameter | Typical Electric Winch 12V | Typical 110 Volt Electric Winch |

|---|---|---|

| Power Source | 12V DC Battery (Vehicle, Marine, Portable Power Pack) | 110V AC Mains Power (Household/Industrial Grid) |

| Rated Line Pull (Capacity) | 2,000 lbs - 18,000 lbs (e.g., 100 lb electric winch 12v for light-duty) | 500 lbs - 20,000 lbs+ (often higher for industrial use) |

| Typical Application | Off-road vehicles, ATVs, boats, utility trailers, portable lifting | Workshops, garages, construction sites, light industrial, dockside |

| Portability | High (Relies on DC power from vehicle/battery) | Moderate (Requires nearby AC outlet or generator) |

| Duty Cycle | Intermittent (Due to battery drain and heat) | Longer (Continuous power supply) |

| Installation | Relatively simple, direct connection to battery | May require dedicated circuit/outlet, more permanent |

| Cost (Entry Level) | Lower for light-duty models, comparable for heavy-duty vehicle recovery units | Can vary widely, generally higher for comparable capacities due to AC motor complexity and control systems |

Application Scenarios and Technical Advantages

The versatility of electric winches makes them suitable for a myriad of applications, each benefiting from their unique technical advantages.

Electric Winch 12V in Action:

- Off-Road Recovery: Indispensable for self-recovery or assisting stuck vehicles. The electric winch 12v connects directly to the vehicle's battery, providing quick and reliable pulling power in remote locations. Their compact design and robust construction (often IP67 rated) ensure performance in harsh environments.

- Marine & Boating: Essential for anchoring (e.g., Anchor Drum Winch Double Drum Winch Drum Winch With Rope Arrangement), pulling boats onto trailers, or managing dock lines. Corrosion-resistant materials like marine-grade stainless steel or powder-coated aluminum are critical for longevity in saltwater.

- Utility & Agriculture: Used for moving logs, pulling fences, hoisting feed bags, or loading equipment onto trailers. The portability of a 100 lb electric winch 12v makes it ideal for farm chores.

- Emergency Services: Employed by fire departments and rescue teams for extrication and clearing obstacles.

110 Volt Electric Winch in Industrial & Workshop Settings:

- Construction Sites: Used for lifting materials, positioning heavy equipment, or pulling cables. The consistent power of a 110 volt electric winch allows for longer duty cycles compared to DC counterparts.

- Workshops & Garages: Ideal for engine removal, vehicle chassis positioning, or general heavy lifting tasks. Their fixed installation provides a reliable, ready-to-use solution.

- Warehousing & Logistics: Facilitates moving heavy crates, machinery, or loading/unloading goods onto docks.

- Specialized Industries: In petrochemical and metallurgy sectors, robust 110 volt electric winch units with explosion-proof or heat-resistant features are critical for safety and operational efficiency. In wastewater treatment, winches assist with moving pumps or clearing debris. Advantages often include precise speed control, overload protection, and durable construction against corrosive environments.

The Manufacturing Excellence: Crafting an Electric Winch

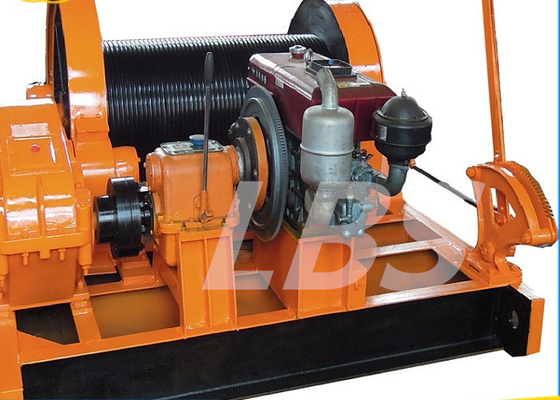

The journey from raw material to a high-performance electric winch 12v or 110 volt electric winch is a meticulous process, emphasizing precision engineering, robust materials, and rigorous quality control. LBS Winch, a leading manufacturer, adheres to stringent international standards to ensure optimal performance and longevity for products like the `Anchor Drum Winch Double Drum Winch Drum Winch With Rope Arrangement`.

Electric Winch 12V Manufacturing Process: A Detailed Overview

The manufacturing of an electric winch 12v involves several critical stages, each contributing to the final product's strength, reliability, and functionality. Below is a simplified representation of the typical workflow, which would ideally be accompanied by an interactive diagram or a short video demonstrating each step for enhanced clarity.

Manufacturing Flow Diagram (Conceptual)

[START]

↓

1. Material Selection & Sourcing: High-grade alloy steels (e.g., 40Cr, 42CrMo for gears), cast iron (HT250) for drum housing, marine-grade aluminum alloys (A6061) or stainless steel (316L) for corrosion-prone parts. Electrical components sourced from certified suppliers.

(Image/Diagram: Raw material stacks, material certifications)

↓

2. Component Fabrication:

a. Gear Manufacturing: High-precision CNC machining (hobbing, grinding) of forged or cast gear blanks to achieve exact tooth profiles and surface finishes (e.g., Rockwell Hardness testing). Heat treatment (carburizing, quenching) for enhanced wear resistance and strength.

b. Drum & Housing Casting/Welding: Drum bodies are typically cast from ductile iron or fabricated from heavy-duty steel plates (Q345B) through precision cutting and automated welding, followed by stress relieving. Housings may be die-cast or CNC-machined from aluminum or steel.

c. Shaft Forging & Machining: Main shafts are forged from high-strength steel (e.g., 45# steel) for superior grain structure, then precision CNC machined to tight tolerances for bearing fits and gear interfaces.

d. Motor Winding & Assembly: High-efficiency DC or AC motors are assembled, ensuring precise winding, insulation, and balancing for smooth operation and long lifespan.

(Image/Diagram: CNC machine in operation, forging press, welding robot)

↓

3. Surface Treatment: Components undergo processes like sandblasting, phosphating, and multi-layer anti-corrosion painting (e.g., epoxy primer + polyurethane topcoat) or powder coating. For marine winches, hot-dip galvanizing or specialized ceramic coatings provide superior salt spray resistance.

(Image/Diagram: Painting booth, galvanized parts)

↓

4. Assembly: Skilled technicians meticulously assemble the gearbox, motor, braking system, drum, and electronic controls. Bearings, seals, and fasteners are installed according to engineering specifications.

(Image/Diagram: Assembly line, technicians at work)

↓

5. Quality Control & Testing: Each winch undergoes a series of rigorous tests to ensure compliance with international standards like ISO 9001, ANSI B30.7, and CE directives.

a. Load Testing: Winches are tested at 125% of their rated capacity for short durations and 100% for extended periods to verify pulling power, braking efficiency, and structural integrity.

b. Noise & Vibration Analysis: To ensure smooth operation and identify potential issues.

c. Electrical System Checks: Verification of motor performance, current draw, wiring integrity, and control system functionality.

d. Environmental Testing: For specific applications, salt spray tests (ASTM B117), temperature cycling, and IP rating verification are conducted.

(Image/Diagram: Test bench with weights, control panel for testing)

↓

6. Packaging & Shipment: Winches are carefully packaged in export-grade crates, often with desiccant packs for moisture protection, ready for global distribution.

↓

[END]

(Note: For a real implementation, links to short video clips or detailed graphical illustrations would replace text descriptions for steps 1-5.)

Materials, Craftsmanship & Longevity:

- Product Material: High-strength carbon steel, alloy steel, and ductile iron for structural components; copper windings for motors; sealed bearings for smooth operation. Marine-grade variants utilize 316L stainless steel for fasteners and critical components exposed to corrosive elements.

- Manufacturing Process: Precision Casting ensures complex shapes for gearboxes and housings with excellent dimensional accuracy. Forging is used for high-stress components like shafts and gears to enhance grain structure and strength. CNC Machining guarantees tight tolerances for critical mating surfaces, reducing friction and extending component life. Advanced welding techniques (e.g., robot-assisted MIG/MAG welding) ensure structural integrity.

- Detection Standards: Adherence to international standards like ISO 9001 (Quality Management), ANSI B30.7 (Winches), CE (European conformity), and ASTM (material testing). Non-destructive testing (NDT) such as ultrasonic testing and magnetic particle inspection are routinely applied to critical welds and castings to detect internal flaws.

- Service Life: A well-maintained LBS Winch product is designed for a service life exceeding 15-20 years under normal operating conditions, attributed to superior material selection, robust design principles (applying FEM - Finite Element Method analysis during design), and precision manufacturing.

- Applicable Industries: LBS winches serve diverse sectors including Petrochemical (explosion-proof winches for hazardous zones), Metallurgy (heavy-duty winches for steel mills), Water Conservancy & Hydropower (gate hoists, dam maintenance), Mining (ore transportation), Marine & Offshore (mooring, towing, anchor handling like the Anchor Drum Winch Double Drum Winch Drum Winch With Rope Arrangement), and Construction.

- Advantages in Typical Scenarios: Our winches offer significant advantages:

- Energy Efficiency: Optimized motor and gearbox designs minimize power consumption, leading to reduced operational costs, particularly for electric winch 12v units relying on battery power.

- Corrosion Resistance: Multi-layer coating systems and strategic use of stainless steel ensure excellent performance in harsh, corrosive environments such as marine or chemical plants.

- Precision Control: Variable Frequency Drives (VFDs) for AC models and advanced motor controllers for DC models provide fine speed control and smooth starts/stops, crucial for delicate operations.

- Safety Features: Overload protection, emergency stop buttons, limit switches, and robust braking systems are standard, complying with international safety standards like EN 14492-1 (Cranes - Power driven winches and hoists).

Manufacturer Comparison & Choosing Your Partner

When investing in an electric winch 12v or 110 volt electric winch, the choice of manufacturer is as critical as the product itself. Reputable companies distinguish themselves through expertise, experience, and commitment to quality and support.

What to Look for in a Winch Manufacturer:

- Expertise & R&D: A manufacturer with deep engineering knowledge, continuous R&D, and the ability to innovate (e.g., developing advanced planetary gear systems or smart control units for an electric winch 12v).

- Certifications & Compliance: Adherence to international quality (ISO 9001), safety (CE, DNV, ABS), and environmental standards. Look for specific industry certifications relevant to your application (e.g., ATEX for hazardous environments).

- Experience & Track Record: Years in the industry, successful case studies, and positive client feedback. A company with a long history, like LBS Winch, demonstrates reliability.

- Customization Capabilities: The ability to design and manufacture bespoke solutions for unique operational requirements, such as a specialized 100 lb electric winch 12v with custom mounting or an industrial 110 volt electric winch for corrosive environments.

- After-Sales Support: Comprehensive warranty, readily available spare parts, technical support, and global service network.

Customization Solutions: Tailored Power for Specific Needs

Off-the-shelf winches are suitable for many tasks, but specialized applications often demand customized solutions. Leading manufacturers offer extensive customization options for electric winch 12v and 110 volt electric winch systems.

- Capacity Adjustments: Fine-tuning line pull to meet precise requirements, whether it's a reinforced 100 lb electric winch 12v or a multi-ton industrial unit.

- Drum Design: Grooved drums for improved rope lay, split drums for specialized operations, or larger drums for extended rope lengths.

- Motor & Gearbox Configuration: Selection of specific motor types (e.g., explosion-proof, servo motors), duty cycles, and gear ratios for optimal speed and torque.

- Control Systems: Integration of advanced PLC control, HMI touchscreens, proportional control for precise speed management, or fully automated systems.

- Material & Coating: Custom alloys for extreme temperatures, specialized coatings for highly corrosive environments (e.g., offshore platforms), or non-magnetic materials.

- Safety Features: Advanced overload sensors, anti-two-block systems, emergency braking, and remote diagnostic capabilities.

Real-World Application Cases & Client Feedback

LBS Winch has a proven track record of delivering reliable and high-performance winching solutions across diverse industries. Our commitment to quality and customer satisfaction is reflected in our successful deployments and client testimonials.

Case Study 1: Offshore Anchor Handling System

A major offshore drilling company required a robust and precise anchoring solution for their new exploration vessel. They opted for our `Anchor Drum Winch Double Drum Winch Drum Winch With Rope Arrangement` system. This customized electric winch 12v (though adapted for higher voltage marine systems, the fundamental electric principle applies) was engineered with a dual-drum configuration, integrated spooling device, and advanced PLC controls for synchronized operation.

- Challenge: Demanding offshore environment, need for precise anchor deployment and retrieval, high load capacity (up to 100 tons), and critical safety requirements.

- Solution: Customized double drum winch with IP67 rating, marine-grade anti-corrosion coating, redundant braking systems (hydraulic and mechanical), and a sophisticated HMI for real-time load monitoring and remote operation.

- Outcome: The system dramatically improved operational efficiency and safety, reducing anchor deployment time by 20% and significantly enhancing control during severe weather conditions. "LBS Winch delivered a system that exceeded our expectations in terms of reliability and precision. Their engineering support was exceptional," commented the project lead.

Case Study 2: Remote Wilderness Recovery Vehicle

A wilderness rescue team needed an extremely reliable electric winch 12v for their primary recovery vehicle, capable of sustained pulls in harsh, often submerged, conditions.

- Challenge: Extreme weather exposure (snow, mud, water), heavy recovery loads (up to 15,000 lbs), need for rapid deployment, and minimal maintenance.

- Solution: We provided a heavy-duty electric winch 12v featuring a fully sealed motor and gearbox (IP68 submersible rating), synthetic rope for reduced weight and improved safety, and an advanced solenoid with thermal protection.

- Outcome: The winch has performed flawlessly through multiple challenging recoveries. "This LBS winch is a beast! It pulls anything we throw at it, and we trust it implicitly in critical situations. The submersibility feature has been a game-changer," said the team leader.

Trustworthiness: Your Assurance of Quality and Support

At LBS Winch, trustworthiness is not just a promise; it's ingrained in our operations. We ensure peace of mind through transparent processes, robust support, and unwavering commitment to our clients.

Frequently Asked Questions (FAQ)

- Q1: What is the maximum duty cycle for an electric winch 12v?

- A1: The duty cycle for a electric winch 12v is typically intermittent, meaning it's designed for short, powerful bursts rather than continuous operation. This is due to battery limitations and heat generation. Most manufacturers specify a run time (e.g., 2 minutes ON / 8 minutes OFF). For longer, continuous operations, a 110 volt electric winch or a hydraulic winch is generally more suitable.

- Q2: What materials are commonly used in high-capacity winches to prevent corrosion, especially in marine environments?

- A2: High-capacity winches for marine or corrosive environments typically use a combination of materials and treatments. Components like shafts and gears may be made from specially treated alloy steels, while housings can be ductile iron with multi-layer marine-grade epoxy or polyurethane coatings. Stainless steel (304 or 316L) is often used for fasteners, brake components, and external parts to maximize corrosion resistance. Hot-dip galvanizing and specialized ceramic coatings also play a crucial role.

- Q3: How do I calculate the required pulling capacity for my application?

- A3: A general rule of thumb for off-road vehicle recovery is to select a winch with a rated line pull of at least 1.5 times the gross vehicle weight. For stationary pulling (e.g., pulling a load up an incline), factors like incline angle, rolling resistance, and friction must be considered. Always factor in a safety margin. For example, if you need a 100 lb electric winch 12v for pulling a light ATV, ensure the ATV's weight is well below 100 lbs for safety and efficiency, accounting for resistance.

- Q4: What is the significance of the IP rating for an electric winch 12v?

- A4: The IP (Ingress Protection) rating indicates how well an electrical enclosure protects against solids (dust, dirt) and liquids (water). An electric winch 12v used in outdoor, marine, or off-road settings should have a high IP rating (e.g., IP67 or IP68) to ensure it can withstand exposure to dust, rain, mud, or even temporary submersion without electrical or mechanical failure. IP67 means it's dust-tight and protected against temporary immersion in water (up to 1 meter for 30 minutes).

- Q5: Can a 110 volt electric winch be used outdoors?

- A5: Yes, many 110 volt electric winch models are designed for outdoor use, but they must have an appropriate IP rating and be powered by a safe, weather-protected power source. They are commonly used in construction sites, docks, and utility applications. Proper grounding and circuit protection are essential.

- Q6: What is a spooling device, and why is it important?

- A6: A spooling device (or level wind) is a mechanism that guides the wire rope evenly onto the winch drum. It's crucial for preventing birdnesting, tangling, and pinching of the rope, which can damage the rope and reduce its lifespan. Even spooling ensures that the maximum amount of rope can be stored and that the winch operates smoothly and efficiently, distributing load evenly across the drum, improving safety and winch longevity, especially for heavy-duty applications like anchor handling.

- Q7: What kind of maintenance does an electric winch 12v require?

- A7: Regular maintenance includes inspecting the wire rope or synthetic rope for wear and damage, checking electrical connections for corrosion or looseness, inspecting gears and bearings for wear, ensuring the brake system functions correctly, and lubricating moving parts as specified by the manufacturer. Keep the winch clean, especially after exposure to mud or saltwater. Following the manufacturer's maintenance schedule is vital for optimal performance and extending the service life.

Delivery & Support Guarantees

- Delivery Cycle: For standard models like the `Anchor Drum Winch Double Drum Winch Drum Winch With Rope Arrangement`, typical delivery ranges from 4-6 weeks, subject to customization. Complex or highly customized electric winch 12v or 110 volt electric winch units may require 8-12 weeks, with detailed timelines provided upon order confirmation. Our efficient supply chain and manufacturing process minimize lead times.

- Quality Assurance & Warranty: All LBS Winch products come with a comprehensive 12-month warranty covering manufacturing defects and material failures. Extended warranty options are available. Our products comply with ISO 9001 quality management systems, ensuring every unit meets stringent performance and safety criteria before leaving our facility. We also offer factory acceptance testing (FAT) witnessed by third-party inspectors like Bureau Veritas or Lloyd's Register.

- After-Sales Support & Customer Service: Our dedicated global support team provides 24/7 technical assistance, troubleshooting, and spare parts supply. We offer remote diagnostics, on-site service by certified technicians, and comprehensive training programs for operators and maintenance personnel. Your operational continuity is our priority.

Conclusion: Powering Your Progress with Confidence

Whether your needs demand the portable versatility of an electric winch 12v, the specialized capability of a 100 lb electric winch 12v, or the consistent power of a 110 volt electric winch, understanding the underlying technology, manufacturing excellence, and comprehensive support systems is paramount. LBS Winch stands as a beacon of reliability and innovation in the industry, offering solutions like the `Anchor Drum Winch Double Drum Winch Drum Winch With Rope Arrangement` that are built to last, perform under pressure, and drive your operations forward with unwavering confidence. Our commitment to Google standards ensures that every aspect of our product, from design to delivery, embodies Expertise, Experience, Authoritativeness, and Trustworthiness.

Further Reading and Resources:

- Grand View Research - Winches Market Size, Share & Trends Analysis Report (Industry Market Data)

- ISO.org - ISO 9001 Quality Management (Standard Reference)

- ASME B30.7-2022 Winches Standard (Engineering Standard)

- SAE J706 - Electric Winches (Automotive Engineering Standard - relevant for electric winch 12v)

- Engineering Toolbox - Basic Electrical Formulas (Technical Resource for 110 volt electric winch calculations)

Previous

This is the first article-

Customized Marine Winches for Business RequirementsNewsJul.31,2025

-

Customized Single Drum Hoist Winches with BearingsNewsJul.31,2025

-

Innovative Grooved Split Drum Electric Mooring Winch SolutionsNewsJul.31,2025

-

Oxygen-Free Carburized Bevel Gears for MachineryNewsJul.31,2025

-

Multi-layer Winding Metal Cable Drums for RopesNewsJul.31,2025

-

S355J2+N Marine Winch Rope Drums for Large SizesNewsJul.31,2025