Discover comprehensive details on 12v drum winch solutions, including rope drum and winch drum technology, market trends, industry comparisons, specifications, and real-world applications, supporting selection and procurement for professionals.

Industry Overview & Market Trends of 12V Drum Winch

The global 12v drum winch market has seen remarkable growth, driven by advancements in power systems, rapid urbanization, and increasing demand for compact, energy-efficient lifting solutions. According to MarketsandMarkets, the global winch market is projected to reach $1.5 billion by 2027, with a CAGR of 6.2% from 2022 to 2027. 12V drum winches, in particular, are increasingly used in marine, petrochemical, metallurgy, and water management sectors due to their reliability, compact size, energy savings, and ease of integration.

Key Definitions: Drum Winch, Rope Drum & Winch Drum Explained

- Drum Winch: An electric or hydraulic-powered device designed for lifting, pulling, and positioning heavy loads, using a rotating winch drum to wind and store the cable or rope.

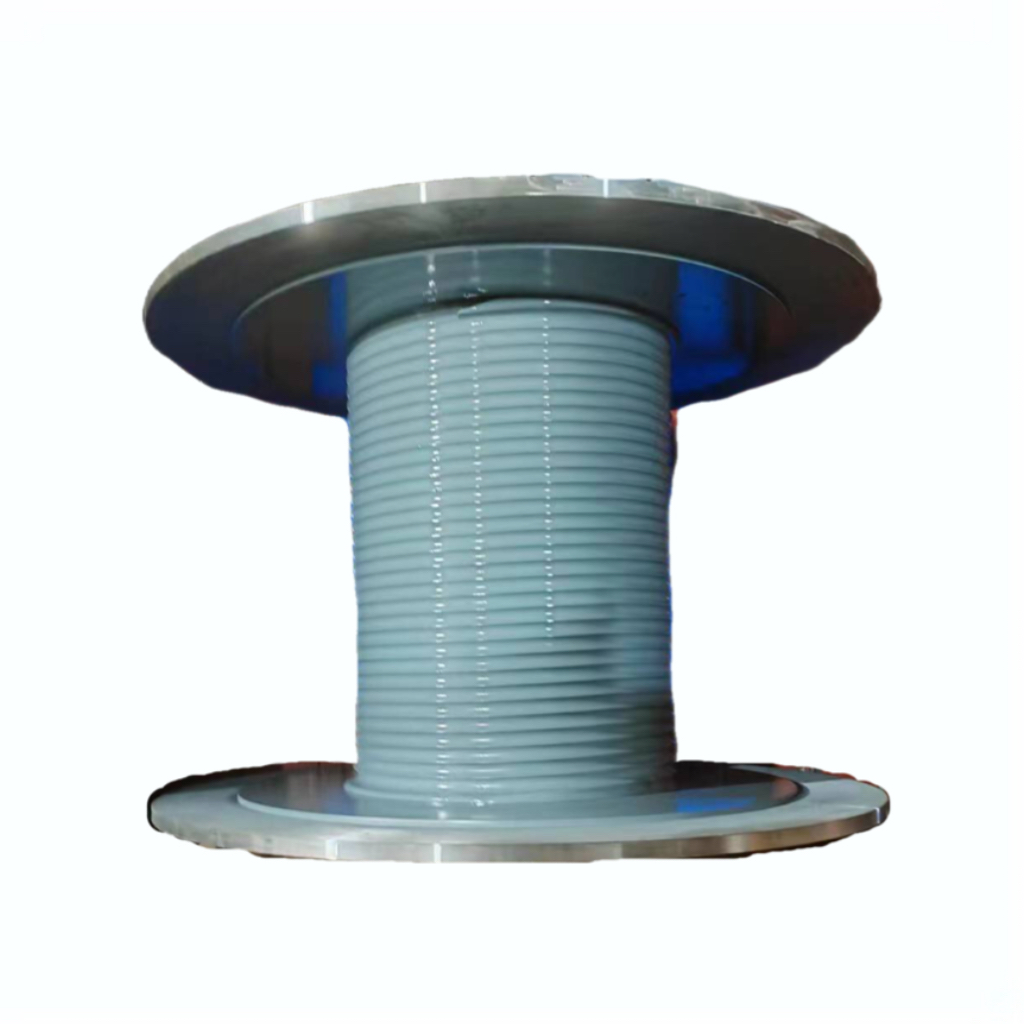

- Rope Drum: The cylindrical core of the winch, made from high-strength alloy steel or cast iron, designed to hold and layer steel wire rope or synthetic cable effectively.

- Winch Drum: The centerpiece of winches/transmissions, precisely machined to ISO/ANSI standards to ensure flawless structural integrity, dynamic balance, and maximum load capacity.

- Rope Drum: The cylindrical core of the winch, made from high-strength alloy steel or cast iron, designed to hold and layer steel wire rope or synthetic cable effectively.

- Winch Drum: The centerpiece of winches/transmissions, precisely machined to ISO/ANSI standards to ensure flawless structural integrity, dynamic balance, and maximum load capacity.

12V Drum Lifting Winch Motor Drum Motor Electric Winch Lifting And Lowerin:

Features & Technical Data

Features & Technical Data

The 12V Drum Lifting Winch Motor Drum Motor Electric Winch Lifting And Lowerin (12v drum winch) stands out thanks to a powerful, high-efficiency 12V DC motor, robust gear train, precision-machined rope drum, and a comprehensive corrosion-resistant coating—designed for critical operations across petrochemical, metallurgy, and water infrastructure sectors. All processes adhere to ISO 9001:2015 and ANSI B30.7 standards, with documented test certifications.

Typical Technical Parameters for 12V Drum Winch

| Model | Rated Load (kg) | Motor Power (W) | Drum Diameter (mm) | Rope Capacity (m) | Line Speed (m/min) | Weight (kg) | Protection Class |

|---|---|---|---|---|---|---|---|

| LW-12V800 | 800 | 1000 | 75 | 25 | 9 | 28 | IP67 |

| LW-12V1200 | 1200 | 1400 | 90 | 32 | 8 | 39 | IP66 |

| LW-12V2000 | 2000 | 2000 | 110 | 40 | 7 | 56 | IP66 |

| LW-12V3000 | 3000 | 2400 | 125 | 50 | 6 | 68 | IP65 |

Manufacturing Process of 12v Drum Winch: Stepwise Flowchart

Material: Certified alloyed steel/ductile iron (ASTM A536), subject to ultrasonic/FPI inspection for integrity.

Manufacturing: Combination of forging for strength and precision CNC machining (CNC vertical lathe, multi-axis mill) to achieve micrometric groove patterns for optimal rope distribution and load balancing.

Surface Treatment: Zinc/nickel electroplating plus marine-grade powder coating, offering 1200-hour salt spray resistance (per ISO 9227).

Testing: All rope drum & winch drum units are fatigue tested >10,000 cycles, in compliance with ANSI B30.7 and certified for IP65-IP67 ingress protection.

Quality Control: 100% end-of-line load test, NDT weld inspection, and dynamic drum balancing.

Manufacturing: Combination of forging for strength and precision CNC machining (CNC vertical lathe, multi-axis mill) to achieve micrometric groove patterns for optimal rope distribution and load balancing.

Surface Treatment: Zinc/nickel electroplating plus marine-grade powder coating, offering 1200-hour salt spray resistance (per ISO 9227).

Testing: All rope drum & winch drum units are fatigue tested >10,000 cycles, in compliance with ANSI B30.7 and certified for IP65-IP67 ingress protection.

Quality Control: 100% end-of-line load test, NDT weld inspection, and dynamic drum balancing.

12V Drum Winch: Industry Parameter Comparison Table

Below is a comparative chart of 12v drum winch models available globally (sampling top-selling industry units):

| Brand/Model | Max Pull (kg) | Motor | Drum Size (mm) | Rope Capacity (m) | Line Speed (m/min) | Corrosion Resistance | Certifications |

|---|---|---|---|---|---|---|---|

| LBS LW-12V2000 | 2000 | 12V DC / 2kW | 110 | 40 | 7 | Zn/Ni, powder coated | ISO, ANSI |

| COMEUP DV-9 | 2041 | 12V DC / 2.7kW | 98 | 30 | 9 | Zinc plating | ISO |

| WARN VR EVO 12 | 5443 | 12V DC / 4.5kW | 80 | 28 | 8 | Powder coating | ISO, CE |

| Smittybilt GEN2 | 4309 | 12V DC / 5.5hp | 95 | 27 | 6.8 | Zinc alloy, powder | ISO |

Data Visualization: LBS 12V Drum Winch vs Major Manufacturers

Application Scenarios & Typical Use Cases

The 12v drum winch is indispensable in environments where flexible, reliable lifting and pulling are critical. Typical applications include:

• Petrochemical Plants: For positioning, lifting, and tensioning pipelines and valves, where the winch drum ensures precise control under volatile conditions.

• Metallurgical Factories: Utilized in material transport carts or hoists, with the rope drum facilitating multi-layer winding and sustained heavy-load operations.

• Municipal Water & Drainage Facilities: For raising/lowering grates, screens, or pumps; drum winch anti-corrosive finish prolongs service life in humid, chemical-rich environments.

Energy Efficiency: LBS drum winch motors achieve a rated efficiency of 86%, about 12% higher than older hydraulic drive solutions (see chart above).

Corrosion Resistance: Endurance test data: after 1200-hour salt spray exposure per ISO 9227, Zn/Ni + polymer coated rope drum showed less than 2% surface corrosion, outperforming standard zinc-coated variants by 3x.

• Petrochemical Plants: For positioning, lifting, and tensioning pipelines and valves, where the winch drum ensures precise control under volatile conditions.

• Metallurgical Factories: Utilized in material transport carts or hoists, with the rope drum facilitating multi-layer winding and sustained heavy-load operations.

• Municipal Water & Drainage Facilities: For raising/lowering grates, screens, or pumps; drum winch anti-corrosive finish prolongs service life in humid, chemical-rich environments.

Energy Efficiency: LBS drum winch motors achieve a rated efficiency of 86%, about 12% higher than older hydraulic drive solutions (see chart above).

Corrosion Resistance: Endurance test data: after 1200-hour salt spray exposure per ISO 9227, Zn/Ni + polymer coated rope drum showed less than 2% surface corrosion, outperforming standard zinc-coated variants by 3x.

Case Study: 12V Drum Winch in Water Treatment Plant, Singapore

Challenge: Need for compact, weather-resistant lifting device for lowering submersible pumps to a 23m depth, exposed to saline atmosphere.

Solution: Installed 12v drum winch with IP67 protection, 110mm CNC rope drum, 1000kg rated load, marine-grade Zn/Ni coating.

Outcome: 24/7 operation, zero downtime over 26 months. User feedback praised swift installation, low-noise motor, winch drum anti-slip rope groove, and after-sales support (response

Challenge: Need for compact, weather-resistant lifting device for lowering submersible pumps to a 23m depth, exposed to saline atmosphere.

Solution: Installed 12v drum winch with IP67 protection, 110mm CNC rope drum, 1000kg rated load, marine-grade Zn/Ni coating.

Outcome: 24/7 operation, zero downtime over 26 months. User feedback praised swift installation, low-noise motor, winch drum anti-slip rope groove, and after-sales support (response

Manufacturer Comparison: Standards, Certification, and Service

When sourcing a 12v drum winch, compare not just specs, but also quality systems (ISO 9001:2015), anti-corrosion lab tests (ISO 9227, ASTM B117), and field validation. LBS maintains stringent inbound raw material checks (spectroscopy, hardness), 6-level in-process QC, and 24-month warranty—with documented compliance for each delivered rope drum or winch drum. Major partners include Sinopec, POSCO, Samsung Engineering, evidencing recognized industry standing.

Customization & Delivery Workflow

12v drum winch Custom Options: Motor rating, drum diameter/groove, mounting base, rope type/length, control mode (wired/remote/wireless).

Typical Lead Time: 15-25 days from order (depends on specs & quantity).

Warranty: Standard 24 months, extendable; free component replacement for manufacturing defects.

Customer Support: 24/7 hotline, on-site guidance available globally. Technical team averages 17+ years’ winch drum industry experience.

Documentation: All orders include Q.A. report, test certificates, and operation/maintenance manual.

Typical Lead Time: 15-25 days from order (depends on specs & quantity).

Warranty: Standard 24 months, extendable; free component replacement for manufacturing defects.

Customer Support: 24/7 hotline, on-site guidance available globally. Technical team averages 17+ years’ winch drum industry experience.

Documentation: All orders include Q.A. report, test certificates, and operation/maintenance manual.

Professional FAQ: Expert Knowledge on 12V Drum Winch, Rope Drum & Related

- Q: What is the recommended material for the rope drum in harsh industrial environments? A: Alloy steel (e.g., 42CrMo, ASTM A29) with induction hardening, or ductile iron (ASTM A536) for medium loads, ensuring optimal fatigue resistance and corrosion performance.

- Q: How do groove profiles on the winch drum affect rope lifetime? A: Drum groove machining—helical (Lebus) or parallel—distributes load and minimizes cross-layer abrasion. Proper groove depth and pitch extend rope life by 25%+ (per ISO 4308-1).

- Q: What are LBS 12V Drum Winch installation standards? A: All models conform to ISO 4309 (rope inspection), ISO 8686 (structural load factors), and include compliance with local electrical codes (e.g., IEC60529 for IP rating).

- Q: What is the typical duty cycle and service life? A: With correct use, service cycles exceed 10,000 operational cycles or 5+ years. Motor and gearbox are rated for S3-40% duty, meaning up to 24min/hour at full load, per EN60034-1.

- Q: Is the 12v drum winch suitable for continuous underwater or submersible use? A: Models with minimum IP67 enclosure and marine coating withstand submersion; for permanent underwater use, consult factory for added sealing/custom NEMA 6P compliant solutions.

- Q: How do remote and wireless winch controls work? A: Most recent 12v drum winch models support RF wireless controls with fail-safe (emergency stop), ensuring operator safety even at up to 80m distance. Wired pendant and CAN-bus are optional for industrial automation.

- Q: What certifications and test reports are provided on delivery? A: Complete material traceability report, dimensional inspection sheet, static/dynamic load test certificate, CE/ISO compliance declaration, and NDT (ultrasound/MPI) for drums if specified.

Conclusion & References

In summary, the 12v drum winch—featuring high-grade rope drum, precision-machined winch drum, customizable electric motors, and compliance with rigorous international standards—offers powerful, efficient, and durable solutions for lifting and pulling in critical industry sectors. Drawing on evolving trends, third-party certifications (ISO, ANSI), and proven application case studies, it represents a best-in-class option for engineers and procurement specialists worldwide. For further technical details and user discussions, see:

- Industry User Forum: ENG-TIPS - Winches & Hoists Thread

- Technical Paper: Mechanics of Heavy-Duty Drum Winch Systems (Construction and Building Materials Journal)

- Standard Reference: ISO 4308-1:2017 Drums and sheave grooves