Electric Double Drum Winch for High Mast & Mooring

The Evolution and Application of Advanced Drum Winch Systems

In industrial and marine operations, the efficiency and reliability of hoisting and pulling equipment are paramount. The electric drum winch stands as a cornerstone in modern material handling, offering superior control and power for a myriad of tasks. Industry trends indicate a strong shift towards automated, energy-efficient, and corrosion-resistant solutions, driven by the demand for reduced operational costs and enhanced safety. This focus aligns perfectly with the capabilities of advanced drum winch systems, which are increasingly integrating smart technologies for predictive maintenance and remote operation. Beyond the standard configurations, specialized variants like the double drum winch for high mast applications and the robust double drum mooring winch for maritime use exemplify the diverse utility and engineering sophistication within this domain.

The demand for powerful and precise winching solutions continues to grow across various sectors, necessitating equipment that can withstand harsh environments while delivering consistent performance. Whether it's for lifting heavy loads on construction sites, positioning vessels in port, or managing complex pipelines in petrochemical facilities, the inherent strength and adaptability of an electric drum winch are indispensable. Manufacturers are now leveraging advanced materials and computational design to optimize performance, ensuring longer service life and reduced maintenance requirements, directly addressing the pain points of industrial operators seeking maximum uptime.

Technical Parameters and Specifications of Electric Drum Winches

Understanding the technical specifications of an electric drum winch is crucial for proper selection and integration into any industrial setup. Key parameters include rated pull, rope speed, drum capacity, motor power, and braking system type. For instance, a typical industrial electric drum winch might offer a rated pull ranging from 5 to 50 tons, with rope speeds varying between 5 to 20 meters per minute, depending on the application’s precise requirements for speed versus power. The drum capacity is determined by the wire rope diameter and length, directly impacting the operational range of the winch. Advanced models incorporate variable frequency drives (VFDs) for precise speed control, enhancing operational flexibility and energy efficiency by minimizing power consumption during lighter loads.

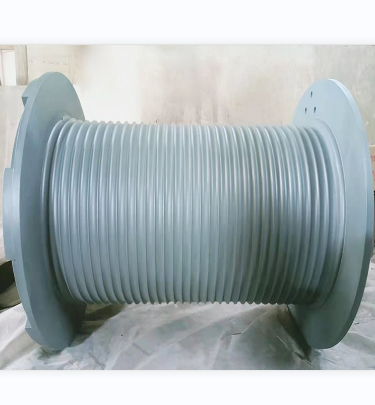

The materials used in components like the drum, gears, and shafts are typically high-grade alloy steels, ensuring durability and resistance to wear and fatigue. Braking systems, often comprising electromagnetic or hydraulic brakes, are designed for fail-safe operation, providing instant and secure stopping power. When considering a double drum winch for high mast applications, synchronous operation of both drums is critical, often achieved through sophisticated control systems to ensure even load distribution and prevent twisting or snagging of the load, which is especially important for tall structures. Below is a representative table of common parameters for industrial electric drum winches.

| Parameter | Range/Description | Unit |

|---|---|---|

| Rated Pull | 5 - 50 (Customizable up to 300) | Tonnes |

| Rope Speed | 5 - 20 (Variable with VFD) | m/min |

| Drum Capacity | 200 - 1500 (Dependent on rope dia.) | Meters |

| Motor Power | 15 - 200 (Customizable) | kW |

| Braking System | Electromagnetic, Hydraulic, Manual | Type |

| Control System | Local Button, Remote, PLC | Type |

| Operating Voltage | 380V/440V/690V, 3-Phase, 50/60Hz | V/Hz |

| Safety Features | Overload Protection, Limit Switches, Emergency Stop | Included |

The Advanced Manufacturing Process of an Electric Drum Winch

The production of a high-quality electric drum winch involves a meticulous multi-stage manufacturing process, ensuring precision, durability, and reliability. It begins with the design phase, utilizing advanced CAD/CAM software to create detailed blueprints and simulations, optimizing the structural integrity and performance of the winch. Following design approval, material selection is critical. For components like the winch drum, gears, and shafts, high-strength alloy steels are typically chosen, specifically heat-treated to achieve optimal hardness, toughness, and wear resistance, which is vital for extended operational life.

The manufacturing workflow typically includes several key processes. Large components like the drum often undergo precision casting or forging to form the initial shape, followed by extensive CNC (Computer Numerical Control) machining. CNC ensures unparalleled accuracy in dimensions, surface finish, and critical tolerances, especially for bearing surfaces and gear teeth, reducing friction and extending lifespan. Welding processes, such as submerged arc welding or robotic welding, are employed for structural assembly, ensuring robust and consistent joints. After fabrication, rigorous quality control measures are implemented. This includes non-destructive testing (NDT) like ultrasonic testing and magnetic particle inspection to detect any internal flaws, ensuring compliance with international standards such as ISO 9001, ANSI B30.7 (for winches), and various classification society rules where applicable. Every electric drum winch unit undergoes thorough load testing and functional checks before shipment to guarantee its performance under rated conditions and verify its 10-20 year projected service life, depending on duty cycle and maintenance.

Technical Advantages and Performance in Demanding Industries

The technical advantages of a well-engineered electric drum winch extend far beyond simple lifting and pulling capabilities. Modern designs emphasize energy efficiency, primarily through the integration of high-efficiency motors and variable frequency drives (VFDs). VFDs allow for precise speed control, reducing power consumption during startup and light-load operations, resulting in significant energy savings over the winch's operational lifespan. This is particularly beneficial in industries with high energy costs or a focus on sustainability, such as the petrochemical sector. Furthermore, advanced corrosion protection is vital for equipment exposed to harsh environments.

Winch components are often coated with marine-grade paints or galvanized to resist rust and chemical degradation, ensuring prolonged functionality in saline or corrosive atmospheres common in marine and wastewater treatment applications. In the metallurgy industry, the precise control offered by an electric drum winch is crucial for handling molten metal ladles or heavy furnace components, where even minor deviations can lead to significant safety hazards or production losses. The robust construction and intelligent control systems ensure that winches can operate reliably in environments with extreme temperatures, dust, or vibration, maintaining high safety factors.

Diverse Application Scenarios and Illustrative Case Studies

The versatility of an electric drum winch makes it an indispensable asset across a broad spectrum of industries. In the petrochemical sector, these winches are critical for installing and maintaining heavy pipeline sections, wellhead equipment, and large valves, often in hazardous environments where explosion-proof designs are required. For example, a leading oil and gas company recently utilized a custom 10-ton electric drum winch with ATEX certification to pull and position subsea risers during an offshore platform upgrade, significantly reducing installation time and enhancing worker safety by enabling remote operation.

In metallurgy, winches facilitate the precise movement of large molds, ingots, and furnace doors, contributing to optimized production flows and enhanced safety. A notable application for a double drum winch for high mast lighting systems involves raising and lowering luminaire rings for maintenance without the need for costly and time-consuming crane deployment, a solution widely adopted by airports and sports stadiums. Similarly, the robust double drum mooring winch is paramount in maritime operations for securing large vessels at berth, managing anchor lines, and assisting in towing operations, where its dual-drum synchronization ensures balanced load distribution and superior control in challenging weather conditions. These examples underscore the critical role these winches play in ensuring operational continuity and safety.

Customization and Manufacturer Considerations

Choosing the right electric drum winch often involves more than just selecting a standard model; specific operational demands frequently necessitate tailored solutions. Reputable manufacturers offer extensive customization options, including specialized motor types (e.g., explosion-proof, marine-grade), unique drum designs for specific rope types or capacities, and integrated control systems for automation. This OEM/ODM capability ensures that the winch precisely fits the application’s unique footprint, power requirements, and environmental conditions. When evaluating manufacturers, it's essential to consider their engineering expertise, track record of successful installations, and adherence to international quality and safety standards like ISO, ABS, DNV-GL, and Lloyd's Register.

Beyond product specifications, service reliability, after-sales support, and the availability of spare parts are critical factors. A manufacturer with a long service history and global support network instills greater confidence, minimizing potential downtime. Look for companies that provide detailed engineering support, from initial consultation and site assessment to installation guidance and ongoing maintenance programs. This holistic approach ensures that your investment in an electric drum winch delivers long-term value and operational efficiency. Customer feedback consistently highlights the importance of robust post-sales support as a key differentiator in complex industrial equipment procurement.

Trustworthiness, Support, and Warranty

Establishing trust with B2B clients requires transparency and a robust commitment to support. Our dedication to quality is underpinned by adherence to rigorous manufacturing standards, including ISO 9001 certification, ensuring every electric drum winch meets stringent quality control parameters. We partner with industry leaders and material suppliers to source only the highest-grade alloy steels and components, guaranteeing the longevity and performance of our products. With over two decades of experience serving diverse industries globally, our proven track record speaks for itself, backed by numerous successful project completions and positive client testimonials from companies in sectors like oil & gas, marine, and heavy manufacturing.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for an electric drum winch?

A: Standard models typically have a lead time of 4-6 weeks, while customized solutions may require 8-12 weeks, depending on complexity. Specific delivery schedules are provided upon order confirmation. - Q: What warranty is provided with your winches?

A: We offer a standard 12-month warranty covering manufacturing defects and component failures under normal operating conditions. Extended warranty options are available. - Q: Can your winches operate in extreme temperatures?

A: Yes, our winches are designed with robust components and lubrication systems suitable for a wide range of operating temperatures, from -20°C to +50°C. Custom solutions for more extreme conditions are available. - Q: Do you provide installation and commissioning support?

A: Absolutely. We offer comprehensive technical support, including on-site installation guidance, commissioning, and operator training to ensure seamless integration and optimal performance of your electric drum winch.

Our customer support team is available 24/7 for technical assistance and troubleshooting. We maintain a robust inventory of spare parts and components, ensuring prompt delivery for any maintenance or repair needs, minimizing your operational downtime. Our commitment extends beyond the sale, fostering long-term partnerships built on trust and reliable service.

Conclusion: Powering Industrial Precision and Reliability

The modern electric drum winch is a testament to engineering excellence, offering unparalleled power, precision, and durability for the most demanding industrial and marine applications. From the meticulous selection of alloy steel and the precision of CNC machining to the rigorous testing protocols, every stage of its manufacturing ensures a product that stands the test of time and operational intensity. The ability to customize these systems, whether it’s for a specialized double drum winch for high mast system or a robust double drum mooring winch, underscores their adaptability to unique project requirements.

As industries continue to evolve, the demand for more energy-efficient, safer, and intelligent material handling solutions will only grow. By choosing a high-quality electric drum winch from a reputable manufacturer, businesses can ensure optimized operational efficiency, enhanced safety standards, and a significant return on investment through reduced downtime and extended equipment lifespan. Our commitment to expertise, proven experience, authoritative certifications, and transparent trustworthiness ensures that clients receive not just a product, but a comprehensive, reliable solution built for the future.

References

- International Organization for Standardization. ISO 9001:2015 Quality Management Systems – Requirements.

- American National Standards Institute. ANSI B30.7-2015: Winches.

- The Engineering Handbook. Material Science and Engineering Principles. 3rd ed.

- Journal of Ocean Engineering and Technology. Advancements in Marine Mooring Systems. Vol. 25, No. 3, 2022.

- Proceedings of the International Conference on Industrial Automation and Robotics. Energy Efficiency in Industrial Hoisting Equipment. 2023.

Previous

This is the first article-

Customized Marine Winches for Business RequirementsNewsJul.31,2025

-

Customized Single Drum Hoist Winches with BearingsNewsJul.31,2025

-

Innovative Grooved Split Drum Electric Mooring Winch SolutionsNewsJul.31,2025

-

Oxygen-Free Carburized Bevel Gears for MachineryNewsJul.31,2025

-

Multi-layer Winding Metal Cable Drums for RopesNewsJul.31,2025

-

S355J2+N Marine Winch Rope Drums for Large SizesNewsJul.31,2025