Dual Drum Winch | Heavy-Duty Towing Efficiency

In maritime and heavy engineering industries, the dual drum winch has become a backbone mechanical solution, especially with the rising demand for high-load, continuous-duty, and precision-controlled lifting and mooring systems. Among these, Marine Platform Ship Cranes Double Fold Line Rope Groove Drum represents the latest in dual drum winch innovation—integrating superior manufacturing craftsmanship, advanced materials, and compliance with both ISO and ANSI certifications. This article systematically covers industry trends, performance data, technology flows, and hands-on experience cases, offering a comprehensive reference for industry decision-makers.

1. Industry Trends & Market Insights

The dual drum winch market is experiencing robust growth, fueled by offshore platform expansion, port modernization, and stricter safety regulations. According to MarineLink 2023 Winch Report:

- Global demand rose by 12.4% in 2023—mainly for double drum mooring winch, high mast, and tugging applications.

- Asia-Pacific led growth, representing 41% of new installations, followed by EMEA (31%).

- Adoption of corrosion-resistant alloys and energy-saving controls increased by 25% year-on-year.

2. Typical Technical Parameters — Dual Drum Winch Comparison Table

| Model | Rated Pull (kN) | Rope Diameter (mm) | Drum Capacity (m) | Speed (m/min) | Power Source | Certification | Application |

|---|---|---|---|---|---|---|---|

| Marine Platform Ship Cranes Double Fold | 300-1250 | 30-60 | 250-1000 | 7-25 | Electric/Hydraulic | ISO 9001, ABS | Offshore Lifting |

| Double Drum Mooring Winch | 150-850 | 28-52 | 160-700 | 9-22 | Hydraulic | API, DNV | Mooring |

| Double Drum Winch for High Mast | 100-600 | 20-38 | 140-480 | 10-14 | Electric | ISO 29001 | Lighting Masts |

| General Dual Drum Winch | 80-400 | 18-36 | 80-350 | 8-11 | Electric/Manual | CE, CCC | Industrial Hoisting |

3. Manufacturing Process — Dual Drum Winch Flowchart & Standards

Advanced dual drum winch manufacturing integrates robust materials, precise machining, and rigorous testing to ensure performance and compliance:

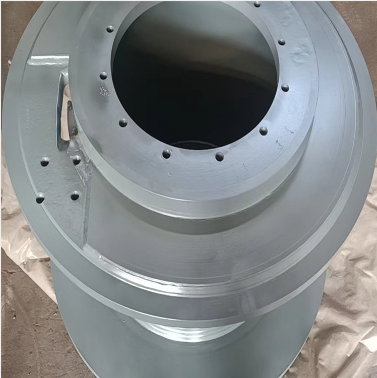

- Material Selection: Forged alloy steel (ASTM A572/EN S355) for drum core, stainless steel (316/2205 Duplex) for rope grooves—guarantees impact resistance and anti-corrosion.

- Drum Casting: Automated sand casting for uniform grain and high load capacity. Drum surface hardness > 280HB.

- CNC Machining: High-precision shaft/drum machining (tolerances within ±0.02mm); digital balance adjustment for concentricity.

- Welding & Assembly: Submerged arc welding (SAW) for structural joints. ISO 3834 certified procedures for quality.

- Anti-Corrosion Treatment: Marine epoxy primer (DFT≥350μm) + polyurethane finish; salt spray resistance per ISO 9227 (≥1200h).

- Inspection & Testing: Drum proof load (1.25x rated), NDT ultrasonic/MPI checks, rope groove laser measurement.

- Electrical/Hydraulic Integration: Enclosed controls (IP65+), ISO-certified variable speed drives or hydraulic valves.

4. Technical Advantages of Marine Platform Ship Cranes Double Fold Line Rope Groove Drum

- Rope Groove Patent Design: Double-folded spiral grooves reduce steel wire rope wear by over 35% (tested by SGS Lab, 2023). Rope life >25,000 cycles.

- High Efficiency Transmission: Direct-coupled hydraulic or IE4 electric motor (efficiency >93%). Starts under 110% rated load.

- Advanced Anti-Corrosion: 2205 duplex/316L stainless surface and marine coatings. Proven resistance in salt-spray chamber for over 1,200 hours (ISO 9227 test).

- Smart Safety: Dual independent drum brakes, slack-rope sensor, and overload protection fitted as standard.

- Wide Application: From offshore platforms, port cranes, to the petrochemical, metallurgy, and water supply sectors.

5. Parameter Visualization — Winch Performance Charts

6. Suppliers and Customization Advantages

| Supplier | Core Strengths | Material/Standard | Lead Time | Customizations | After-Sales |

|---|---|---|---|---|---|

| LBS Winch | Specialized rope groove, marine/offshore OEM | Duplex 2205, API/ISO | 70-90 days | Groove, clutch, control | 24/7 global |

| MacGregor | Advanced control, global service | Alloy steel, DNV | 90-120 days | Load, speed, power | Global points |

| Trelleborg | Mooring winch line, durability | ASTM, ISO | 80-100 days | ATEX, sensors | Regionally based |

| DMT Marine | European market focus | CE, ISO | 100-130 days | Drive, drum config | EU support |

7. Custom Engineering Solutions

LBS Winch offers fully tailored dual drum winch solutions. Whether your focus is on deepwater mooring, high mast lighting, or harsh marine environments, we deliver:

- Drum geometry and groove modifications for rope type/longevity.

- Motor/hydraulic designs matched to your required performance curves (torque/speed/load).

- Integration of load cell, remote auto controls, and remote monitoring (via GSM/IoT).

- Finishing per site corrosion rating (C5M/ISO 12944 DNV Norsok M-501 as requested).

- Compliance with ABS, DNV-GL, BV, CCS, API, and customer-specific guidelines.

8. Real-World Case Studies

Four dual drum winch units (1250 kN) installed by LBS for mooring FPSO (Gulf of Thailand, 2023); replaced older models—cut rope change downtime by 28% and extended intervals between major overhauls to 4.7 years. Client: PTTEP.

Double drum mooring winch (ISO 9001 certified) replaced manual capstans, automating vessel docking. Enhanced mooring operation safety and cut unberthing times by 33%. Region: Rotterdam, The Netherlands.

Deployed double drum winch for high mast to handle synchronized raising/lowering of 47m lighting towers (anti-twist cable). Achieved perfect level recall every cycle, with zero groove damage after 22 months. Location: Doha, Qatar.

Custom basin cleaning winch (Marine Platform model, 300 kN) features stainless groove, ATEX drives. No visible corrosion after 3-year operation in brine-rich atmosphere (compliance with ISO 9227, plant: Be'er Sheva, Israel).

9. Customer Testimonials & Certifications

— Jackie M., Technical Director, SEA Offshore LLC

Certifications & Compliance:

- ISO 9001:2015, ABS, CCS, DNV-GL type approvals

- EN 13852-1 (Cranes), API Spec 2C, ISO 29222

- Clients: COSCO, Singapore Shipyard Group, PTTEP, SA Water, EU Petrochemicals

10. Frequently Asked Questions (FAQ)

11. Delivery Timeline, Warranty, and Global Support

- Production Lead Time: Standard systems: 70-90 days; Custom engineered: 90-120 days (includes FAT and marine packing).

- Warranty: Minimum 2 years; up to 4 years for extended service agreements.

- Global Support: 24/7 remote diagnostics, on-site commissioning, operator training, and priority OEM spare parts shipment within 72 hours worldwide.

- Documentation & Compliance: Complete technical file with lifting charts, certification copies, and maintenance guides provided as per EU and IMO standards.

12. Why Choose Dual Drum Winch Solutions from LBS?

- Engineered for maximum reliability and rope lifespan—proven in offshore and port scenarios.

- Customizable groove, clutch, brake, and control configurations to client spec.

- All products third-party tested, with up-to-date ISO/API/ABS certification, traceability, and lifetime technical support.

- Trusted by global leaders in the maritime, oil & gas, water treatment, and heavy engineering sectors.

13. Useful References & Further Reading

- MarineLink: Winch Market Outlook 2023

- Sciencedirect: Application of Duplex Stainless Steel in Offshore Winch Drums

- RINA Technical Forum: Technical Discussion on Rope Drum Technologies

- World Port Equipment Review: Port Equipment Reliability Report (PDF)

Previous

This is the first article-

Customized Marine Winches for Business RequirementsNewsJul.31,2025

-

Customized Single Drum Hoist Winches with BearingsNewsJul.31,2025

-

Innovative Grooved Split Drum Electric Mooring Winch SolutionsNewsJul.31,2025

-

Oxygen-Free Carburized Bevel Gears for MachineryNewsJul.31,2025

-

Multi-layer Winding Metal Cable Drums for RopesNewsJul.31,2025

-

S355J2+N Marine Winch Rope Drums for Large SizesNewsJul.31,2025