Double Drum Winch for High Mast | Safe, Durable, Precise

double drum winch for high mast,double drum mooring winch,mechanical drum winch is a key solution in the Mechanical equipment manufacturing industry, specifically within Manufacturing of lifting and transportation equipment and Winch manufacturing. This article explores how Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- double drum winch for high mast,double drum mooring winch,mechanical drum winch Overview

- Benefits & Use Cases of double drum winch for high mast,double drum mooring winch,mechanical drum winch in Winch manufacturing

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Mechanical equipment manufacturing industry

- Conclusion on double drum winch for high mast,double drum mooring winch,mechanical drum winch from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

double drum winch for high mast,double drum mooring winch,mechanical drum winch Overview

In the Mechanical equipment manufacturing industry, double-drum configurations are chosen when operators need independent or synchronized control over two wire ropes. A double drum winch for high mast enables safe raising and lowering of luminaires or maintenance platforms on tall poles, while a double drum mooring winch offers precise line handling and redundancy for marine and offshore operations. A mechanical drum winch typically refers to a gear-driven drum system—powered by electric or hydraulic motors—with robust brakes and a torque-optimized gearbox.

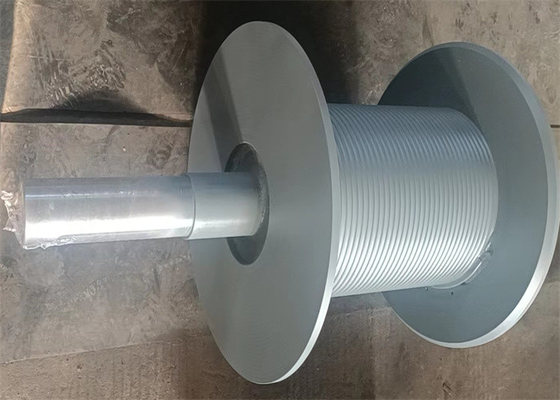

Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. engineers and manufactures winch drums and complete winch solutions featuring precision LBS (Lebus-style) grooved drums that promote orderly spooling, consistent line pull, and reduced wire rope wear. Typical specifications are customized per project and may include line pull from 5–120 t, drum diameters from 300–1600 mm, rope diameters from 8–64 mm, single or split-drum designs, band or disc brakes, and options for local/remote control. For a high-mast application, dual drums can separate hoist and safety lines, each with its own brake and load limiter. In marine mooring, a double drum layout supports active line and storage/stand-by line, improving deck efficiency and safety. As a winch manufacturing partner, Junzhong delivers application-fit engineering, material traceability, and thorough factory testing.

Benefits & Use Cases of double drum winch for high mast,double drum mooring winch,mechanical drum winch in Winch manufacturing

In winch manufacturing, the double drum platform provides versatility across high mast, marine, and industrial handling scenarios.

- High mast: Independent hoist and rescue/safety lines for stadiums, ports, highways, and tall maintenance poles, ensuring controlled, redundant lifting.

- Marine mooring: Two-drum sets for active mooring and spare line, with load monitoring to maintain safe line tension in changing sea states.

- Industrial handling: Synchronized pulls, counter-pulls, or dual-point lifting in plants, yards, and construction sites.

Competitive advantages include LBS grooved mechanical drum winch geometry for perfect layer-by-layer winding, which stabilizes line pull and minimizes crushing and abrasion. High torque gearboxes, fail-safe multi-disc brakes, and optional frequency inverters (VFD) or proportional hydraulic controls deliver smooth starts, precise speed control, and secure holding. For harsher environments, corrosion-resistant materials, C5M coatings, and sealed bearings extend service life. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. brings deep sector expertise from winch drum manufacturing to turnkey assemblies, integrating encoders, load cells, over-tension protection, and emergency release functions according to project requirements. The result is a double drum mooring winch or double drum winch for high mast that aligns with your safety, performance, and uptime targets.

Cost, Maintenance & User Experience

Total cost of ownership in lifting and transportation equipment is a function of acquisition, installation, energy consumption, wire rope life, maintenance, and downtime. By using LBS grooved drums, Shijiazhuang Junzhong’s mechanical drum winch keeps rope spooling tight and parallel, reducing premature rope wear and unplanned replacements. Energy-optimized gear ratios and optional VFDs or load-sensing hydraulics can cut power draw during light-load cycles, while robust braking systems minimize heat and lining wear.

Maintenance is straightforward: routine rope inspection and lubrication, gearbox oil checks, brake lining and spring checks, and periodic verification of load and limit devices. Many B2B users in the Manufacturing of lifting and transportation equipment sector report smoother line payout, fewer bird-nesting incidents, and quicker rope changes due to accessible drum flanges and guided entry sheaves. Over a typical multi-year lifecycle, these factors translate into higher uptime and measurable ROI—especially on high mast lighting networks and mooring stations where labor access is costly. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. supports preventive maintenance schedules, spare-part kits, and remote assistance to keep operations within budget and on schedule.

Sustainability & Market Trends in Mechanical equipment manufacturing industry

Sustainability in the Mechanical equipment manufacturing industry is increasingly shaped by energy efficiency, longer component life, and responsible materials. Trends in winch manufacturing include electrification with regenerative braking where feasible, low-friction bearing systems, and coatings that reduce environmental impact while improving corrosion resistance. Smart sensors for condition monitoring help predict rope and brake servicing, minimizing waste and preventing failures that could result in emergency interventions.

Regulatory expectations and best practices are also moving toward enhanced safety functions, data logging, and operator-friendly HMIs. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. aligns with these trends by optimizing drum groove patterns to extend rope life, offering efficient drives and control packages, and supporting refurbishment programs that extend service life rather than replace entire systems. For marine and coastal environments, engineered coatings and material selection mitigate corrosion, while modular designs make upgrades—such as adding load monitoring or remote control—straightforward. The outcome is a double drum winch for high mast or double drum mooring winch solution that is safer, more energy-aware, and better suited to evolving compliance and ESG goals.

Conclusion on double drum winch for high mast,double drum mooring winch,mechanical drum winch from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

A well-engineered double drum winch for high mast, a robust double drum mooring winch, or a precision mechanical drum winch can transform operational safety, efficiency, and lifecycle value. With proven LBS grooved drums, application-specific engineering, and reliable after-sales support, Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. is a trusted partner across lifting and transportation equipment projects.

Contact us: email: lbswinch@lebus.com.cn

Visit our website: https://www.lbswinch.com

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025