Double Drum Mooring Winch | High Capacity, Marine-Grade

A candid look at double drum mooring winches: specs, trends, and real-world notes

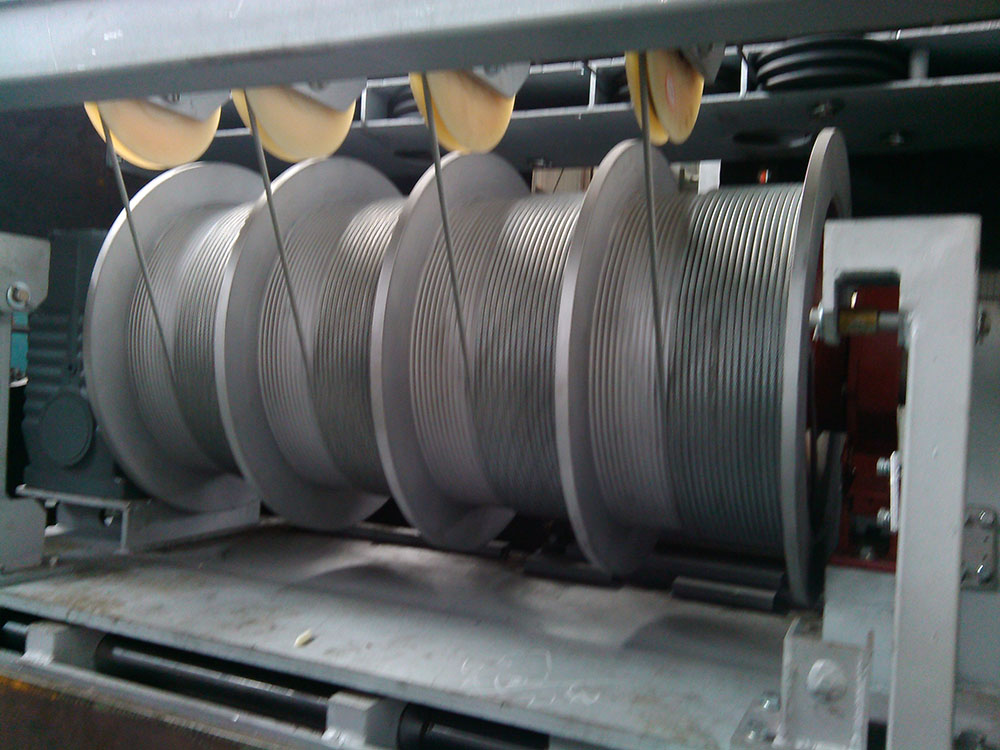

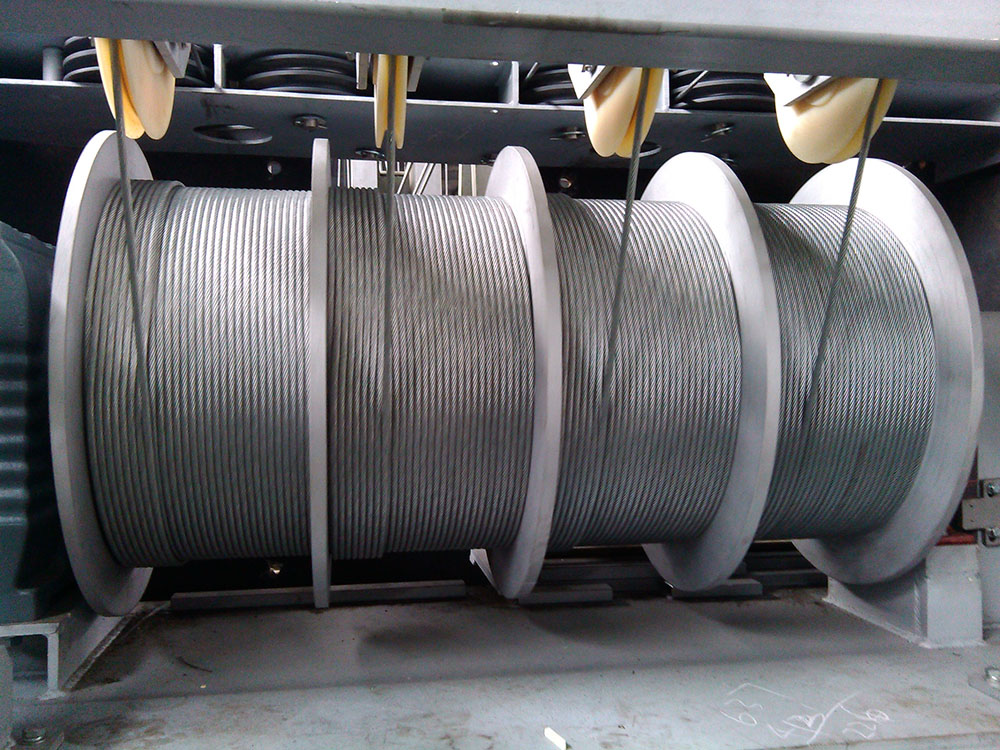

If you’re weighing up a double drum mooring winch for a vessel refit or newbuild, here’s the straight talk from the shop floor and the pier. The gear in question is built in NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China—where the supply chain is surprisingly fast when specs are locked early. To be honest, the recent pivot toward grooved drums and sensorized controls isn’t hype; it fixes rope management headaches we used to accept as “normal.”

Industry trend check

In 2024–2025, yards are asking for higher brake holding factors (≥1.8× SWL), integrated load cells, and coatings rated C5M. Many customers say the grooved drums cut spooling damage and crew interventions—especially with HMPE lines. And yes, hybrid-electric drives are quietly replacing pure hydraulics on workboats, driven by energy goals and maintenance budgets.

Typical specifications (real-world may vary)

| Rated pull | ≈ 50–300 kN at 1st layer |

| Line speed | 10–18 m/min (continuous) |

| Drum arrangement | Twin drums, grooved; split or waterfall |

| Brake holding | ≥ 1.8–2.0 × SWL |

| Rope capacity | Up to ≈ 200–400 m (Ø 36–48 mm) |

| Drive | Electric or hydraulic; VFD / proportional control |

| Protection & coating | IP56 motors; paint system C5M |

| Certifications | ABS, DNV, BV, LR (on request) |

Process flow, materials, and testing

- Materials: marine steel (e.g., Q355B) for frames; alloy shafts; seamless drum shells with precision grooving.

- Methods: CNC machining, robotic welding, stress relief, groove milling; dynamic balancing of drums.

- NDT: UT/MT on critical welds; hydrostatic tests on hydraulic manifolds.

- Factory tests: no-load and load tests up to 1.1× rated pull; brake verification to ≥1.8× SWL; noise checks (ISO 3744).

- Service life: around 15–25 years with annual class surveys; C5M coating for harsh splash zones.

Applications and a quick case

You’ll see the double drum mooring winch on offshore support vessels, tugs, FPSOs, jack-up barges, and even land rigs where synchronized pulls matter. A recent Southeast Asia tug refit swapped aging kit for a grooved double drum mooring winch; crew reported 30–40% fewer rope layering corrections and noticeably steadier payout during surge. Small win, big morale boost.

Vendor snapshot (indicative)

| Vendor | Lead time | Price band | Cert support | Customization |

|---|---|---|---|---|

| LBS Winch (Hebei) | ≈ 6–10 weeks | Value | ABS/DNV/BV/LR | High (grooved, sensors) |

| European OEM A | 10–16 weeks | Premium | Strong | High |

| Korean OEM B | 8–12 weeks | Mid–High | Strong | Medium |

Customization and buying notes

- Options: auto-tension, line counters, load pins, warping heads, remote/PLC integration.

- Commercials: FOB ≈ US $0.5–9,999 per piece; MOQ ~100; capacity ≈ 10,000 pcs/month (batch projects scale well).

- Paperwork: class approvals, FAT reports, coating DFT logs, material certs (EN 10204 3.1).

Field feedback: “Quieter than our old hydraulics and the grooved layer holds shape better in swell.” Not scientific, but it matches test data we’ve seen—line speed stability within ±5% and brake holding routinely verified above 1.8× SWL.

Citations

- OCIMF, Mooring Equipment Guidelines (MEG4), 4th Ed.

- DNV Rules for Ships, Pt.4 Ch.5 – Mooring and Anchoring Equipment.

- ABS Steel Vessel Rules – Equipment for Mooring and Anchoring.

- ISO 3744: Acoustics — Determination of sound power levels of noise sources.

- DNV-ST-0378: Standard for Offshore and Platform Lifting Appliances (related testing practices).

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025