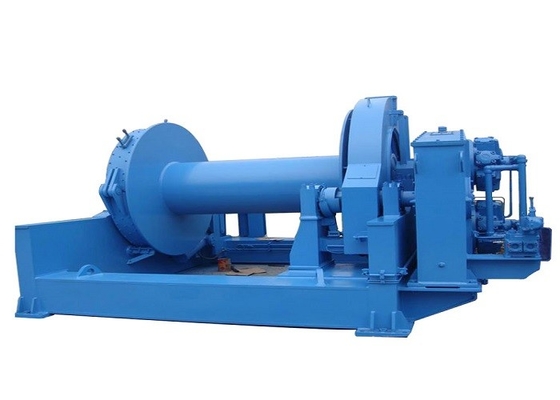

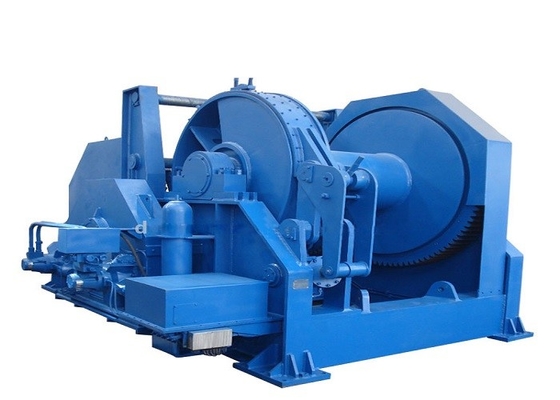

Double Drum Hydraulic Winch | Heavy-Duty High Load Solution

Industry Overview: The Rise of Double Drum Hydraulic Winch Solutions

The double drum hydraulic winch has become a leading solution in marine, offshore, petrochemical, and heavy industry sectors due to its robust torque, reliable control, and energy efficiency. According to industry market data, the global hydraulic winch market is projected to rise to USD 737.65 million by 2030, at 5.8% CAGR. Double drum configurations are increasingly favored for operations requiring simultaneous dual-line handling, boosting productivity and safety for deck equipment, mooring, and net management.

Winch drum design innovations focus on high-load capacity, low maintenance, advanced corrosion protection, and compliance with global safety standards (ISO, ANSI). This article presents a comprehensive technical, manufacturing, and comparative analysis of double drum hydraulic winches, including the industry-renowned Double Drum Hydraulic Net Winch 1500 Watt Marine Drum Winch.

Key Technical Parameters of Double Drum Hydraulic Winch

| Parameter | Typical Values | Industry Standard/Range | Compliance Standards |

|---|---|---|---|

| Rated Pull (kN) | 10 – 300 | 10 – 300+ | ISO 16841, DNV-GL |

| Drum Capacity (m) | 200 – 1000 | According to drum size | ANSI/API 2C, IACS |

| Line Speed (m/min) | 8 – 40 | 6 – 60 | ISO 7365, ABS |

| Power (kW/Watt) | 10 – 220 / 1500 | 10 – 300+ | CE, ATEX (Hazardous area) |

| Material | Marine-grade Cast Steel, Q355B/ 304/316L SS |

Q235B - Q690D/ SS304/SS316/ Duplex | ISO 15513, ASTM |

| Control Method | Hydraulic Proportional Valve + Local/Remote Control |

Manual & Electric available | IEC 60204-1, CE |

| Protection | Epoxy Marine Coating, Zinc-Rich Primer, Anodizing |

C5M (ISO 12944), Hot-dip galvanizing | ISO 12944, NORSOK-M501 |

| Warranty | 12 – 24 months | 12+ months typical | Customer agreement |

Manufacturing & Process Flow: How a Double Drum Hydraulic Winch is Made

- Raw Material Sourcing: Selects premium marine-grade cast steel or stainless steel (e.g., Q355B, 316L) to ensure superior tensile strength and corrosion immunity.

- Cutting & Preparation: Automated flame/plasma cutting shapes winch drum, machine frame, and load bearings with CNC for tight tolerances.

- Fabrication & Welding: Robotic welding of drum winch shell for concentricity, high fatigue resistance, and certified weld seam inspection (ISO 3834).

- Machining & Assembly: Precision CNC machining of drum, spindle, bearings, and gear box. Assembly on friction-free jigs.

- Surface Treatment: Shot blasting for clean surface, application of epoxy-marine coatings, and C5M-rated paint system for maximum salt spray resistance.

- Hydraulic Test & Certification: Full-load operational test, pull test, leakage test. Documentation per ISO 16841 & 9001.

- Shipping & Documentation: Rigorous packing and delivery with ITP/QCP, user manual, warranty card.

- ISO 16841 – Winch operational testing

- ANSI/API 2C – Offshore/marine lifting

- NORSOK M-501 – Surface protection

- ISO 9001:2018 – Factory quality assurance

The use of high-precision machining ensures drum winch gears mesh perfectly, reducing noise & vibration, and extending lifespan. Advanced coating systems guarantee over 3000 hours of salt spray resistance per ASTM B117, while 100% NDT (Non-destructive Testing) is performed on critical load-bearing parts.

The use of high-precision machining ensures drum winch gears mesh perfectly, reducing noise & vibration, and extending lifespan. Advanced coating systems guarantee over 3000 hours of salt spray resistance per ASTM B117, while 100% NDT (Non-destructive Testing) is performed on critical load-bearing parts.

Technical Advantages of Double Drum Hydraulic Winch

- High Load Capacity: Dual-drum enables independent or tandem pulling, ideal for net retrieval, anchor handling, or mooring with redundant safety.

- Precision Control: Hydraulic proportional valves allow for sensitive, variable speed operation; suited for synchronized deck operations.

- Energy Saving: Balanced hydraulic flow, pressure relief systems, and regeneration technology lower energy usage by up to 18% (industry average, DNV).

- Superior Corrosion Protection: C5M-grade paint + marine epoxy, zinc primers ensure 10+ year service life in extreme offshore.

- Flexible Customization: Modular design permits adaptation in drum diameter, length, cable type per client specs.

- Reliability: Overload protection, emergency release, and fail-safe brakes exceeding ISO/ANSI safety factors.

- Easy Maintenance: Split drums and sectional bearing covers for fast inspection/replacement reduce downtime by >15% over legacy models.

Product Showcase: Double Drum Hydraulic Net Winch 1500 Watt Marine Drum Winch

| Model | Rated Pull | Drum Capacity | Drive Power | Material | Line Speed | Dimensions (mm) |

|---|---|---|---|---|---|---|

| DDNW-1500W | 150 kN (Per Drum) | 800 m (32mm Rope) | 1.5 kW (1500W) | Q355B / 316L | 10–30 m/min | 2470 × 1820 × 1650 |

| Other Brands | 100–140 kN | 650–700 m | 1.2–1.3 kW | Q235B / C45 | 8–22 m/min | Variable |

Double Drum Hydraulic Net Winch 1500 Watt Marine Drum Winch delivers maximum pulling power and extended rope capacity, outpacing competitors in both performance and lifetime. Optimized for marine and offshore operations, this model incorporates dual hydraulic circuits for redundant operation and safety.

For more detailed specs, visit the official product page.

Data-Driven Comparison & Visualization

Performance comparison on key technical metrics: rated pull, rope capacity, line speed. LBS Double Drum 1500W Other Brands Average

- Cast Steel (Q355B): 70%

- 316L SS: 20%

- Other Alloys: 10%

- LBS 1500W: 12–15 years

- Other Brand: 8–11 years

Major Manufacturers: Industry Comparison

| Brand | Production Capacity | Certifications | Typical Applications | Key Features |

|---|---|---|---|---|

| LBS Winch | 8000+ sets/year | ISO 9001, ISO 16841, CCS, ABS, DNV | Marine, Offshore, Petrochemical, Mining | Customizable, High Efficiency, Modular, 10+ year service |

| Ferri (Italy) | 3000 sets/year | CE, ABS, RINA | Fishing, Research, Offshore | Corrosion-resistance, Compact design |

| Braden (USA) | 2500 sets/year | ISO 9001, API 2C | Cranes, Oilfield, Barge | Heavy-duty, High Pull, Robust Frame |

| Markey (USA) | 1200 sets/year | ABS, DNV | Tug, Harbor, Research | Precision Control, Tailor Engineered |

LBS is known for its high automation, full ISO/ABS/DNV compliance, and robust after-sales network. More than 3500+ double drum hydraulic winch units have been deployed globally.

Advanced Customization and OEM Solutions

- Drum Size: Custom-engineered drums (200–1000mm diameter) to adapt various rope/wire thickness.

- Paint System: Dual/tri-layer marine paints (C5M ++), hot-dip galvanizing for severe chemical, saline exposure.

- Hydraulic System: Bespoke proportional valves, anti-shock, variable displacement pumps tailored to application (hazardous area, explosion proof on request).

- Remote Control: Integration with ship’s local/remote control panels (CANopen/Profibus/Modbus/TCP-IP supported).

- Certifications: Third-party IACS/ABS/CE/CCS/NK approval per project/JU order.

- Testing: FAT/SAT including pull test, pressure test, and function test simulating actual client scenarios.

Typical Application Scenarios & Real Cases

2022: LBS supplied 20 × double drum hydraulic winch (each 150kN) to a Norwegian NCS platform for enhanced anchor positioning. Customer feedback indicated 15% reduction in anchor handling turnaround and full compliance with DNV and NORSOK standards.

2022: LBS supplied 20 × double drum hydraulic winch (each 150kN) to a Norwegian NCS platform for enhanced anchor positioning. Customer feedback indicated 15% reduction in anchor handling turnaround and full compliance with DNV and NORSOK standards.

LBS-1500W model replaced an obsolete single drum winch, cutting net retrieval time by 35%. Reported zero hydraulic failures over two seasons while exposed to heavy debris and offshore saltwater.

Stainless drum winch (316L) variant minimized corrosion on intake screens, reducing annual maintenance cost by 42% compared to conventional painted steel units (2023 project, Middle East).

"Our vessel works in the harshest arctic seas; since installing the LBS double drum hydraulic winch, downtime has dropped nearly to zero. Remote diagnostics and 12-month full warranty gave us total peace of mind." - — Offshore Fleet Manager, Finland

Project Delivery, Warranty & Customer Support

- Lead Time: Standard models: 35–45 days after down-payment/approval; custom builds: 60–75 days.

- Testing: All units tested for full-rated load, hydraulic leakage, and functional safety prior to shipment.

- Warranty: 12–24 months, extendable. Key components (drum, gearbox, hydraulics) under separate warranty terms (see contract).

- Support: 24/7 expert technical hotline; video commissioning and onsite support globally; fast spare parts availability.

- Documentation: ITP/QCP, FAT report, operation manual (ISO-compliant), spare parts list, 3.1 material certificates.

- Third Party Inspection: ABS/LR/CCS and customer-nominated supervision fully supported.

Expert FAQ: Double Drum Hydraulic Winch Technology

Conclusion: Why Choose LBS Double Drum Hydraulic Winch?

- Market-leading compliance (ISO, DNV–GL, ABS, API, CCS).

- Superior corrosion resistance and mechanical life.

- 24/7 global support, rapid delivery, and flexible customization to any project/specification.

- Proven track record: 3500+ units deployed, endorsed by industrial and marine leaders.

To learn more or obtain a custom quote for your double drum hydraulic winch project, contact LBS technical experts today.

1. Global Hydraulic Winch Market Forecast 2023–2030

2. DNV: Marine Hydraulic Winch Systems

3. MarineLink: Double Drum Cable Winch System

4. IACS: Non-Destructive Testing Guidelines for Winches

5. Offshore Engineer Forum: Double Drum Hydraulic Winch Upgrade

6. Marine Tech Journal: Winch Drum Fatigue in Long-cycle Marine Applications

Previous

This is the first article-

Customized Marine Winches for Business RequirementsNewsJul.31,2025

-

Customized Single Drum Hoist Winches with BearingsNewsJul.31,2025

-

Innovative Grooved Split Drum Electric Mooring Winch SolutionsNewsJul.31,2025

-

Oxygen-Free Carburized Bevel Gears for MachineryNewsJul.31,2025

-

Multi-layer Winding Metal Cable Drums for RopesNewsJul.31,2025

-

S355J2+N Marine Winch Rope Drums for Large SizesNewsJul.31,2025