-

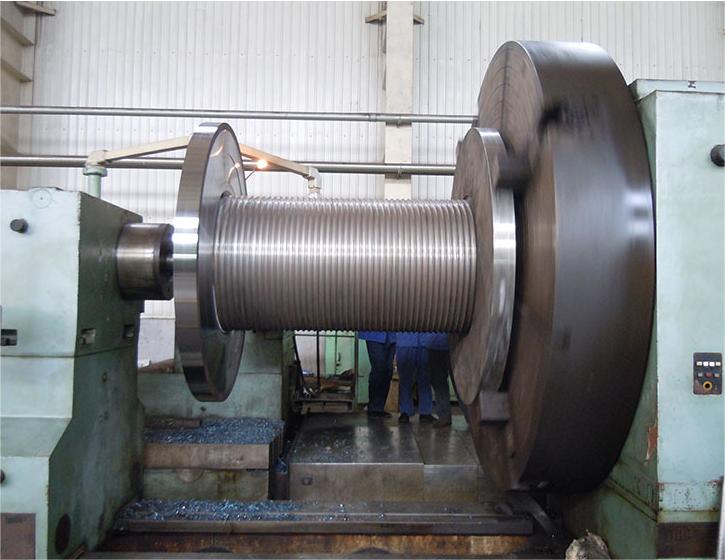

1500 Meter Capacity Carbon Steel Rope Groove Winch Drum For Petroleum Drilling Equipment

A typical lebus built drum is composed of a welded plain drum and a welded grooved shell. In the event of a malfunction, simply replacing the sleeves can greatly save costs and reduce expenses.

-

Hydraulic Drive Crane Winch LBS Rope Slot Winch Drum Smoothly Winding

The LBS series slot type winch drum is widely used in various construction and engineering projects. This includes water conservancy engineering, forestry, mines, docks, etc. It can be effectively used for material lifting or flat dragging. In addition, it can also be used as an auxiliary device for certain modern automation operations.

-

Design According To The Diagram Steel Wire Rope Drum With A Shaft Accessories For Crane

The term “double folded wire rope groove” currently popular in the Chinese lifting industry refers to a type of wire rope suitable for multi-layer production introduced from abroad, with its winding groove form. Due to the fact that this type of rope groove remains parallel to the flange end face in most sections of the drum circumference, and only in a small area, the cross-section intersects with the flange end face, the rope groove inevitably bends. Therefore, it is named “double line rope groove” and is a specialized rope winding technique.

A typical lebus constructed drum consists of a welded flat drum and a welded groove shell. In the event of a malfunction, simply replacing the sleeve can greatly save costs and reduce expenses. -

Customized Processing Of Large Mining Winch Drum LBS Groove sleeve

The LBS series Grooved Winch Drum is widely used in a variety of construction and engineering projects. These include water conservancy projects, forestry, mines, wharves, and more. It can be used effectively for material lifting or flat dragging. Additionally, it can be used as a auxiliary equipment for certain kinds of modern automated operations.

-

Customized Left-hand Or Right-hand Drilling Rig Winch Drum Special Rope Groove

The term “double fold line wire rope groove” currently popular in the lifting industry in China refers to a type of steel wire rope suitable for multi-layer production introduced from abroad winding rope groove form. Due to the fact that this type of rope groove remains parallel to the flange end face in most sections of the drum circumference, only in a very small area the section intersects with the flange end face, so the rope groove will inevitably experience bending, hence the name “double fold line rope groove” and make it for a specialized rope winding technique.

-

S355J2+N large Diameter Rope Drum marine wnch

Product name:S355J2+N Large Diameter Rope Drum For Large Quipment Marine Winch Other name: Winch drum. Standard:NS-ISO 13920BF Sling type:cable or wire power: Electirc colour : Blue white Rope: 100-1000mm Rope diameter: 3-199mm Tolerance General: Ns-iso 2768mK Our company mainly serves lifting machinery, Marine machinery, petroleum machinery, water conservancy machinery, We can produce winches and all steel parts for winches Product name Rope winch drum Drum Quantity Single Or Double ... -

Lebus grooved drum with ratchet for ocean surveying winch

Electric winch is widely used in heavy work and large traction required. The motor of the single-drum electric winch drives the drum through the reducer, and a brake is arranged between the motor and the input shaft of the reducer. In order to meet the needs of lifting traction and rotary operations, there are double and multiple reel winches. The structure Electric winch is composed of base, gear box, motor, cable arrangement machinery, electrical control box, frequency converter box, hand-h... -

Customized Non-standard wire rope multi-layer winding LEBUS grooved winch drum

Grooved Winch Drum

Material: Carbon Steel, Alloy Steel, Stainless Steel, Aluminum, High-Strength Steel, Etc

Material Standards: GB, AISI, ASME, ASTM, JIS, DIN, …

Ambient Temperature: -40 ° C To +45 ° C

Stroage Ambient Temperature: -40 ° C To +50 ° C

Groove Type of Drum: Spiral Grooves or Lebus Grooves

The Rotation Direction of The Drum: Lefthand or Righthand

Processing method: Machine Work

Wire Rope Diameter: 3 MM~100 MM

Processing Equipment: CNC machining center

-

Customized Non-standard wire rope multi-layer winding LEBUS grooved winch drum

Grooved Winch Drum

Material: Carbon Steel, Alloy Steel, Stainless Steel, Aluminum, High-Strength Steel, Etc

Material Standards: GB, AISI, ASME, ASTM, JIS, DIN, …

Ambient Temperature: -40 ° C To +45 ° C

Stroage Ambient Temperature: -40 ° C To +50 ° C

Groove Type of Drum: Spiral Grooves or Lebus Grooves

The Rotation Direction of The Drum: Lefthand or Righthand

Processing method: Machine Work

Wire Rope Diameter: 3 MM~100 MM

Processing Equipment: CNC machining center -

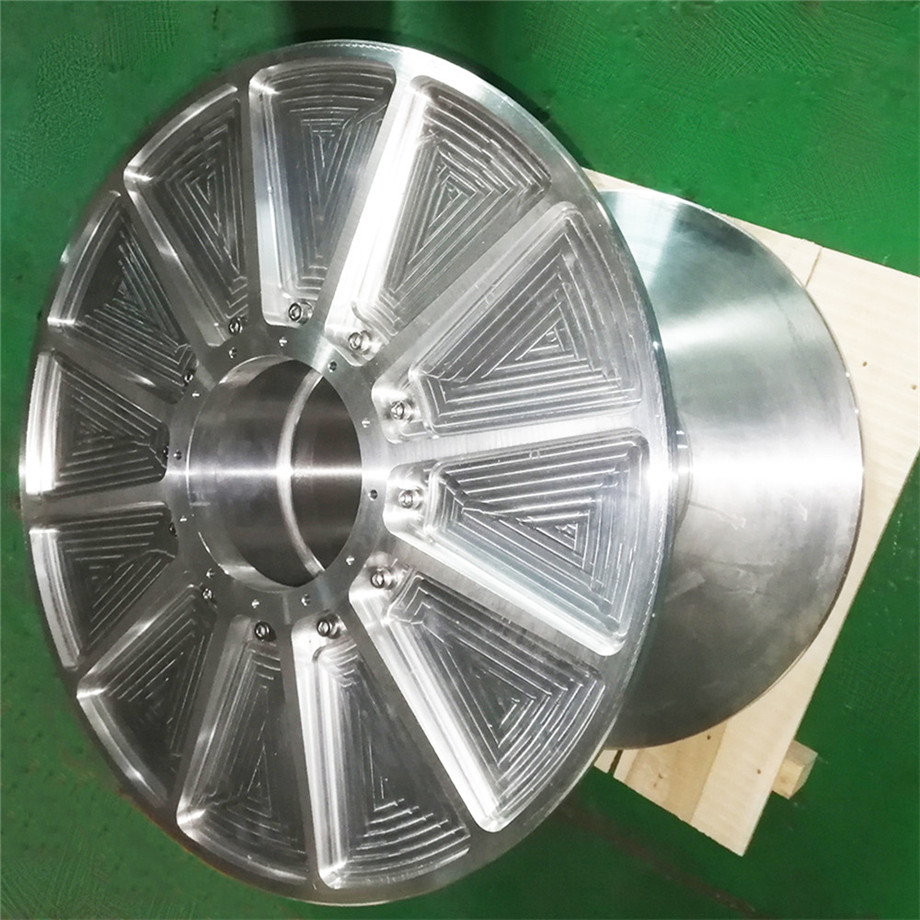

wire rope winding Drum of Aluminum Alloy Material

winch is one of the important optional equipment of the helicopter. The winch on the helicopter is generally an electric winch,

The electric winch can carry out lifesaving and lift the wounded or personnel from the ground to the helicopter cabin in the hovering state of the helicopter. In the hovering state of the helicopter, lift the refueling tube, helicopter hovering refueling, reduce the helicopter refueling time, that is, reduce the preparation time of flight tasks; Hang the cable on the hook of the winch, rope down the personnel, so that the personnel quickly descend to the ground to perform the task; Lifting and transporting light cargo; Aerial lifting personnel to carry out aerial work. With the continuous progress and development of helicopter technology, electric winch technology is also constantly improving, and playing an irreplaceable role in more and more fields. -

Multiple grooved Winch Drum For BMU

Window cleaner is commonly used for cleaning and maintenance of Windows and external walls of buildings or structures. Mainly by walking mechanism, bottom frame, winch system, column, rotary mechanism, boom (telescopic arm mechanism); The winch system is the most important part. Its design is directly related to the structure layout of the whole machine, working reliability, stability, wire rope life and the stability of the whole machine.

LEBUS grooved double or multiple drums group produced by our company, suitable for all kinds of window cleaning machine, to solve the rope in multi-layer winding rope problem. -

lebus grooved drum for tower crane

ower crane is a rotating crane whose boom is mounted on the top of the towering tower. It is mainly used for vertical transportation of materials and component installation in construction of multi-storey and high-rise buildings. It is composed of metal structure, working mechanism and electrical system. The metal structure includes tower body, boom, base, attachment rod, etc. The working mechanism has four parts: lifting, luffing, turning and walking. Electrical system includes motor, controller, distribution frame, connecting circuit, signal and lighting device, etc.

The drum is an important part of the tower crane, which plays the role of hoisting or lowering heavy objects by winding the wire rope.

The wire rope must be correctly wound on the winch drum to proceed smoothly. A drum with a rope groove helps to wind the wire rope neatly and avoid wire rope disorder. The winding of the wire rope should be as smooth as possible, so as to give full play to the performance of the wire rope and prolong the service life. If there is a rope guide groove on the drum, it will help the winding smoothly, our company produces LEBUS rope groove drum, it is to realize the smooth winding of the rope