-

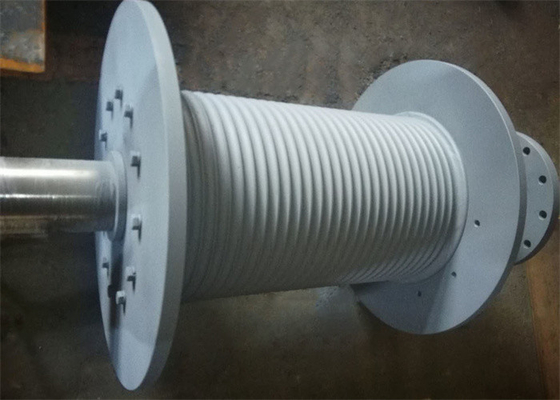

Drum Walking Tractor Winch Transfer Gear With Shaft

The term “double fold line wire rope groove” currently popular in the lifting industry in China refers to a type of steel wire rope suitable for multi-layer production introduced from abroad winding rope groove form. Due to the fact that this type of rope groove remains parallel to the flange end face in most sections of the drum circumference, only in a very small area the section intersects with the flange end face, so the rope groove will inevitably experience bending, hence the name “double fold line rope groove” and make it for a specialized rope winding technique.

A typical lebus built drum is composed of a welded plain drum and a welded grooved shell. In the event of a malfunction, simply replacing the sleeves can greatly save costs and reduce expenses. -

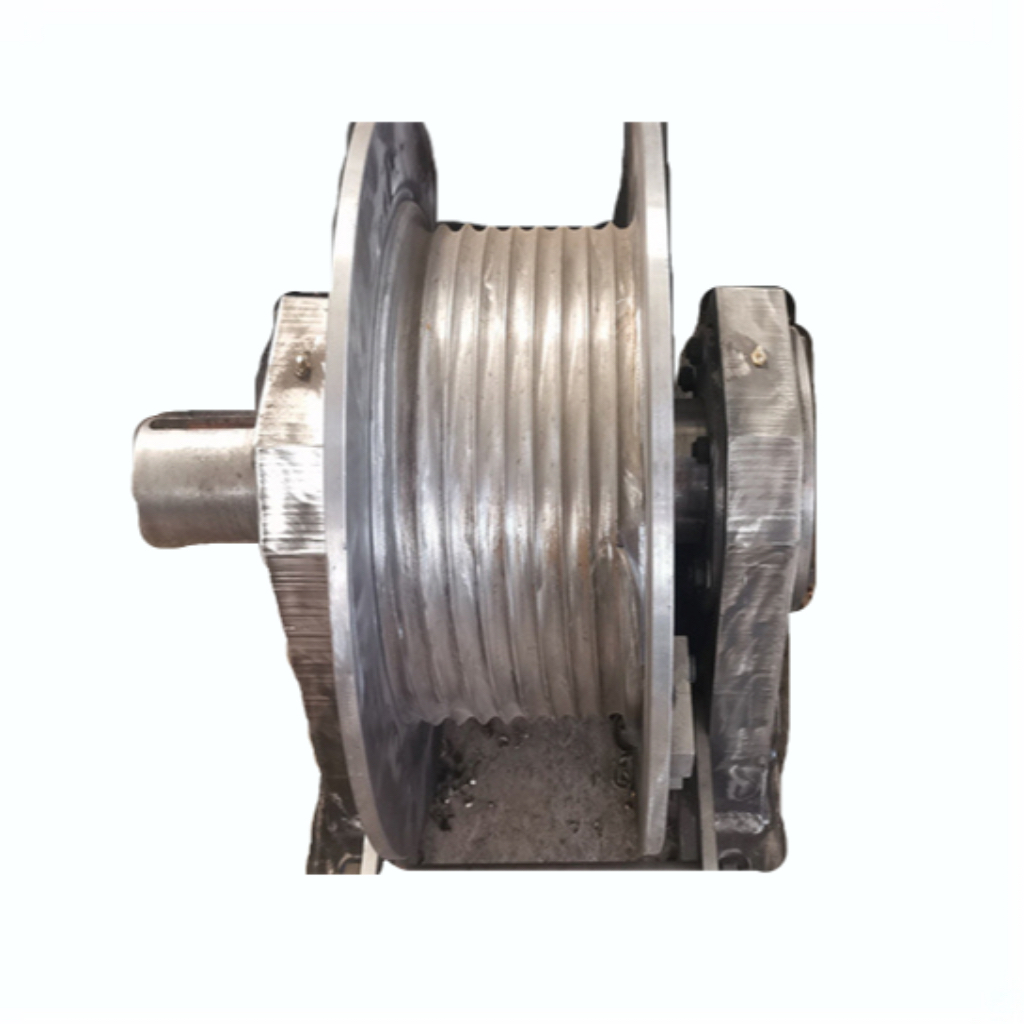

Single Drum Hoist Winch Small Single Drum Winch Waterfall Winch With Bearing Customized

Hoisting and lifting are the main functions of the grooved drum, which uses the spiral and vertical or lebus system groove to help the rope wrap smoothly and achieve the purpose of lifting heavy objects. It mainly includes offshore platform crane winch, port and wharf crane winch, Tower crane winch, crawler crane winch and gantry crane winch.

The grooved barrel can be divided into flange and non flange, as well as shaft and non shaft.

-

Drum Anchor Winch Carbon Steel Drum Winch Drum Longline Winch

The term “double fold line wire rope groove” currently popular in the lifting industry in China refers to a type of steel wire rope suitable for multi-layer production introduced from abroad winding rope groove form. Due to the fact that this type of rope groove remains parallel to the flange end face in most sections of the drum circumference, only in a very small area the section intersects with the flange end face, so the rope groove will inevitably experience bending, hence the name “double fold line rope groove” and make it for a specialized rope winding technique.

A typical lebus built drum is composed of a welded plain drum and a welded grooved shell. In the event of a malfunction, simply replacing the sleeves can greatly save costs and reduce expenses.

-

4 Drum Winch Drum Mooring Winch Multi Layer Winding

In recent years, our products have been widely used in the fields of offshore platform cranes, oil workover drilling winches, logging rope winding equipment, wall wiping machine winches, helicopter motor winches, and so on. With its high reputation, high-quality products and service system, it has received widespread praise from domestic and foreign customers.

-

Winch Drum Stainless Drum Winch For 12 Meter Vessel

Hoisting and lifting are the main functions of the grooved drum, which uses the spiral and vertical or lebus system groove to help the rope wrap smoothly and achieve the purpose of lifting heavy objects. It mainly includes offshore platform crane winch, port and wharf crane winch, Tower crane winch, crawler crane winch and gantry crane winch.

The grooved barrel can be divided into flange and non flange, as well as shaft and non shaft.

-

Small Drum Double Drum Winch Mining Scraper Winch Other Winches

Hoisting and lifting are the main functions of the grooved drum, which uses the spiral and vertical or lebus system groove to help the rope wrap smoothly and achieve the purpose of lifting heavy objects. It mainly includes offshore platform crane winch, port and wharf crane winch, Tower crane winch, crawler crane winch and gantry crane winch.

The grooved barrel can be divided into flange and non flange, as well as shaft and non shaft.

-

Winch Drum Winch Drum Manufacturer Single Drum With Shaft

Hoisting and lifting are the main functions of the grooved drum, which uses the spiral and vertical or lebus system groove to help the rope wrap smoothly and achieve the purpose of lifting heavy objects. It mainly includes offshore platform crane winch, port and wharf crane winch, Tower crane winch, crawler crane winch and gantry crane winch.

The grooved barrel can be divided into flange and non flange, as well as shaft and non shaft.

-

Oxygen Free Carburizing Spur Bevel Gear For Transmission Machinery

A gear is a mechanical component with teeth that mesh with each other. Widely used in mechanical transmission and the entire mechanical field. Modern gear technology has reached: gear module 0.004~100mm; The gear diameter ranges from 1 millimeter to 150 meters; The transmission power can reach 100000 kilowatts; The rotational speed can reach hundreds of thousands of RPM; The maximum circumferential speed is 300 meters/second.

-

Winch Drum Planetary Gear Gate Gas Winche 5 Tones Wire Cable Drum

The Grooved Drum is widely used in a variety of construction and engineering projects. These include water conservancy projects, forestry, mines, wharves, and more. It can be used effectively for material lifting or flat dragging. Additionally, it can be used as a auxiliary equipment for certain kinds of modern automated operations.

The LBS series Grooved Winch Drum is driven by a gear reducer, which provides an efficient and reliable means of powering material hoists. As such, it is suitable for many different applications, such as civil construction and the installation of projects from construction and mining companies, and even factories.

-

Quadruple Winch Drum Wire Rope Steel Drum Winch Drum 100 kg Lifting Winch

Hoisting and lifting are the main functions of the grooved drum, which uses the spiral and vertical or lebus system groove to help the rope wrap smoothly and achieve the purpose of lifting heavy objects. It mainly includes offshore platform crane winch, port and wharf crane winch, Tower crane winch, crawler crane winch and gantry crane winch.

The grooved barrel can be divided into flange and non flange, as well as shaft and non shaft.

-

12V Drum Lifting Winch Motor Drum Motor Electric Winch Lifting And Lowerin

The term “double fold line wire rope groove” currently popular in the lifting industry in China refers to a type of steel wire rope suitable for multi-layer production introduced from abroad winding rope groove form. Due to the fact that this type of rope groove remains parallel to the flange end face in most sections of the drum circumference, only in a very small area the section intersects with the flange end face, so the rope groove will inevitably experience bending, hence the name “double fold line rope groove” and make it for a specialized rope winding technique.

A typical lebus built drum is composed of a welded plain drum and a welded grooved shell. In the event of a malfunction, simply replacing the sleeves can greatly save costs and reduce expenses. -

Split Drum Winch Winch Grooved Drum Electric Winch Drum

The term “double fold line wire rope groove” currently popular in the lifting industry in China refers to a type of steel wire rope suitable for multi-layer production introduced from abroad winding rope groove form. Due to the fact that this type of rope groove remains parallel to the flange end face in most sections of the drum circumference, only in a very small area the section intersects with the flange end face, so the rope groove will inevitably experience bending, hence the name “double fold line rope groove” and make it for a specialized rope winding technique.

A typical lebus built drum is composed of a welded plain drum and a welded grooved shell. In the event of a malfunction, simply replacing the sleeves can greatly save costs and reduce expenses.