-

Folded Rope Groove Automatic Rope Arranging Winch Drum Leather Manufacturer Direct Sales

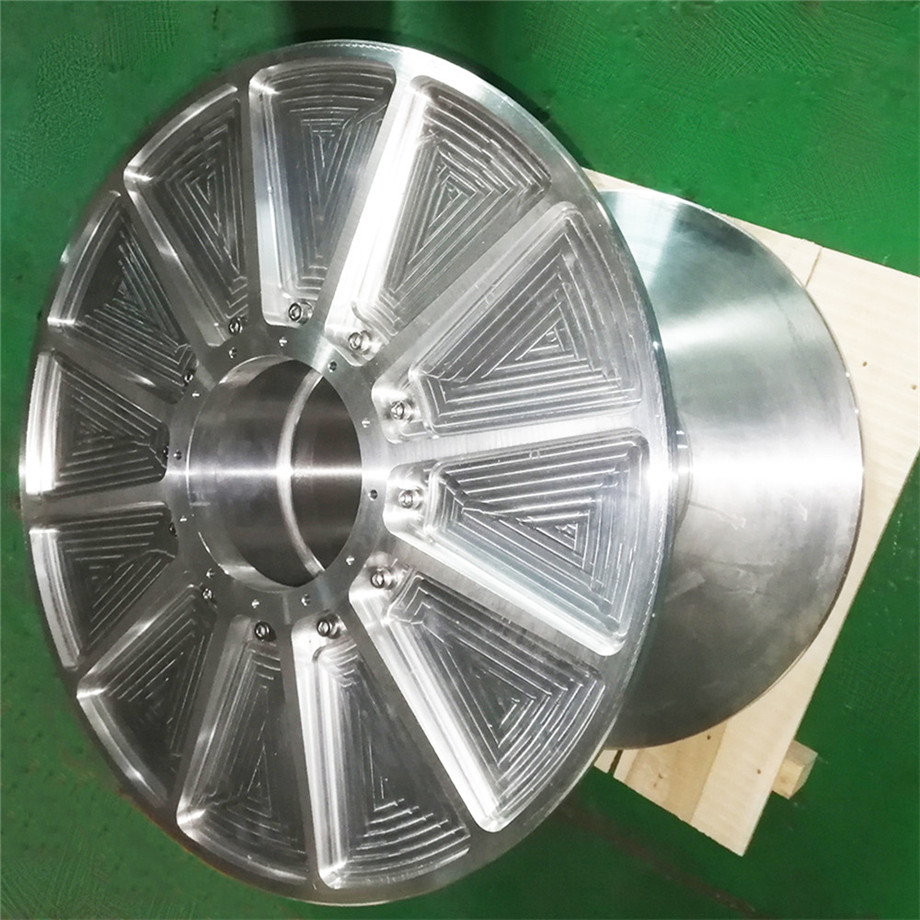

Split LBS rope groove drum skin:

Process a smooth drum into a LBS rope groove structure, and then divide it into two pieces, each consisting of a section consisting of inclined rope grooves and parallel grooves. It can be installed on drums with smooth grooves or spiral grooves.Split LBS rope groove leather: It is an effective and economical solution. If it is necessary to replace different types and sizes of ropes or damaged drums in the future, you can only replace the new LBS rope groove leather instead of replacing or repairing the entire drum component, saving costs for customers.Integrated LBS rope groove drum:

A drum with grooves directly inserted into it (with or without bolts or welding flanges as required). Process the LBS rope groove directly on the drum. -

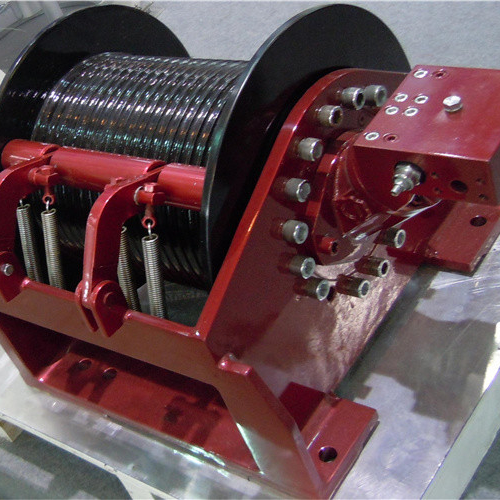

CCS Approval Smooth Drum 10 KN Hydraulic Crane Winch For Mining

hydraulic crane winch ,The drum is LEUBS grroved, the material is alloy steel, rope capacity is 300m, the brake type is Multiple disc brake, the The power rating is 10T.

-

S355J2+N large Diameter Rope Drum marine wnch

Product name:S355J2+N Large Diameter Rope Drum For Large Quipment Marine Winch Other name: Winch drum. Standard:NS-ISO 13920BF Sling type:cable or wire power: Electirc colour : Blue white Rope: 100-1000mm Rope diameter: 3-199mm Tolerance General: Ns-iso 2768mK Our company mainly serves lifting machinery, Marine machinery, petroleum machinery, water conservancy machinery, We can produce winches and all steel parts for winches Product name Rope winch drum Drum Quantity Single Or Double ... -

offshore equipment 650KN eletric winch with CCS certification

The winch converts the electric energy into mechanical energy through the motor, that is, the rotor of the motor rotates the output, through the triangle belt, shaft, gear, and then drives the drum to rotate after deceleration. The reel winds the wire rope 7 and passes through the pulley block to make the crane hook lift or drop the load Q, change the mechanical energy into mechanical work, and complete the vertical transport loading and unloading work of the load.

-

Customized Non-standard wire rope multi-layer winding LEBUS grooved winch drum

Grooved Winch Drum

Material: Carbon Steel, Alloy Steel, Stainless Steel, Aluminum, High-Strength Steel, Etc

Material Standards: GB, AISI, ASME, ASTM, JIS, DIN, …

Ambient Temperature: -40 ° C To +45 ° C

Stroage Ambient Temperature: -40 ° C To +50 ° C

Groove Type of Drum: Spiral Grooves or Lebus Grooves

The Rotation Direction of The Drum: Lefthand or Righthand

Processing method: Machine Work

Wire Rope Diameter: 3 MM~100 MM

Processing Equipment: CNC machining center

-

Lebus grooved drum with ratchet for ocean surveying winch

Electric winch is widely used in heavy work and large traction required. The motor of the single-drum electric winch drives the drum through the reducer, and a brake is arranged between the motor and the input shaft of the reducer. In order to meet the needs of lifting traction and rotary operations, there are double and multiple reel winches. The structure Electric winch is composed of base, gear box, motor, cable arrangement machinery, electrical control box, frequency converter box, hand-h... -

Split sleeves for efficient use

The LEBUS split-sleeve system consists of a pair of outer shells that are bolted or welded onto a smooth drum to provide a grooving pattern. Either helical or LEBUS parallel grooves can be carved into the sleeves.

As with all LEBUS drums, the grooving in split sleeves is engineered to match the specific rope construction, diameter and length, and to suit the application.

When the split type drum fence skin is installed, the split fence skin sleeve is wrapped on the smooth slotless drum, and is closely connected with the drum through bolts or welding, so that the original smooth surface of the drum outside the surface becomes the form of lebus double folding rope groove, which is convenient for the application of winch modification or replacement of the drum. -

Customized Non-standard wire rope multi-layer winding LEBUS grooved winch drum

Grooved Winch Drum

Material: Carbon Steel, Alloy Steel, Stainless Steel, Aluminum, High-Strength Steel, Etc

Material Standards: GB, AISI, ASME, ASTM, JIS, DIN, …

Ambient Temperature: -40 ° C To +45 ° C

Stroage Ambient Temperature: -40 ° C To +50 ° C

Groove Type of Drum: Spiral Grooves or Lebus Grooves

The Rotation Direction of The Drum: Lefthand or Righthand

Processing method: Machine Work

Wire Rope Diameter: 3 MM~100 MM

Processing Equipment: CNC machining center -

wire rope winding Drum of Aluminum Alloy Material

winch is one of the important optional equipment of the helicopter. The winch on the helicopter is generally an electric winch,

The electric winch can carry out lifesaving and lift the wounded or personnel from the ground to the helicopter cabin in the hovering state of the helicopter. In the hovering state of the helicopter, lift the refueling tube, helicopter hovering refueling, reduce the helicopter refueling time, that is, reduce the preparation time of flight tasks; Hang the cable on the hook of the winch, rope down the personnel, so that the personnel quickly descend to the ground to perform the task; Lifting and transporting light cargo; Aerial lifting personnel to carry out aerial work. With the continuous progress and development of helicopter technology, electric winch technology is also constantly improving, and playing an irreplaceable role in more and more fields. -

Multiple grooved Winch Drum For BMU

Window cleaner is commonly used for cleaning and maintenance of Windows and external walls of buildings or structures. Mainly by walking mechanism, bottom frame, winch system, column, rotary mechanism, boom (telescopic arm mechanism); The winch system is the most important part. Its design is directly related to the structure layout of the whole machine, working reliability, stability, wire rope life and the stability of the whole machine.

LEBUS grooved double or multiple drums group produced by our company, suitable for all kinds of window cleaning machine, to solve the rope in multi-layer winding rope problem. -

lebus grooved drum for tower crane

ower crane is a rotating crane whose boom is mounted on the top of the towering tower. It is mainly used for vertical transportation of materials and component installation in construction of multi-storey and high-rise buildings. It is composed of metal structure, working mechanism and electrical system. The metal structure includes tower body, boom, base, attachment rod, etc. The working mechanism has four parts: lifting, luffing, turning and walking. Electrical system includes motor, controller, distribution frame, connecting circuit, signal and lighting device, etc.

The drum is an important part of the tower crane, which plays the role of hoisting or lowering heavy objects by winding the wire rope.

The wire rope must be correctly wound on the winch drum to proceed smoothly. A drum with a rope groove helps to wind the wire rope neatly and avoid wire rope disorder. The winding of the wire rope should be as smooth as possible, so as to give full play to the performance of the wire rope and prolong the service life. If there is a rope guide groove on the drum, it will help the winding smoothly, our company produces LEBUS rope groove drum, it is to realize the smooth winding of the rope -

Split type lebus grooved sleeves of nylon or steel materials

Lebus grooved system is the most effective and perfect method to prolong the life of wire rope. LBS rope groove makes the load evenly distributed between layers, and the practice proves that it greatly prolongs the life of wire rope. In fact, the test surface can extend wire rope life by more than 500%. Reducing wire rope damage increases safety and reduces machine downtime.