Products

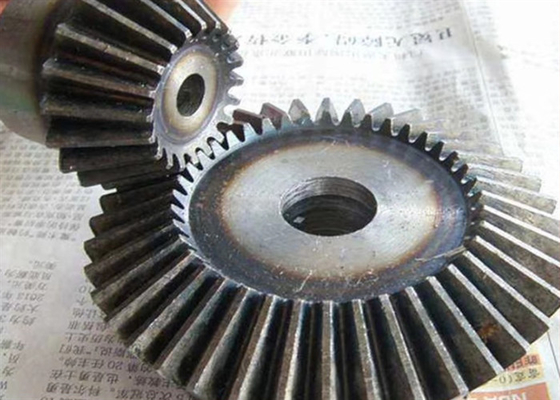

Oxygen Free Carburizing Spur Bevel Gear For Transmission Machinery

Products Description

Overview of gears

A gear is a mechanical component with teeth that mesh with each other. Widely used in mechanical transmission and the entire mechanical field. Modern gear technology has reached: gear module 0.004~100mm; The gear diameter ranges from 1 millimeter to 150 meters; The transmission power can reach 100000 kilowatts; The rotational speed can reach hundreds of thousands of RPM; The maximum circumferential speed is 300 meters/second.

What is a spur gear

Straight teeth are a classification method for gears, known as Spur Gear. According to the relative position and tooth direction of a pair of gear axes (whether the two circles are parallel), it can be divided into planar gear rotation and spatial gear rotation; According to the different working conditions of gears, they can be divided into open transmission and closed transmission; According to the shape of gear teeth or tooth profiles, they are divided into straight teeth, helical teeth, herringbone teeth, or straight teeth, curved teeth.

Application of spur gears

Straight gears are mainly used to reduce speed and increase torque. In some consumer goods products, they are also used for high-speed transportation. The following are the applications of spur gears in several products: mixers, washing machines, cars, bicycles, mechanical clocks, etc Advantages of spur gears: simple design, easy manufacturing, low cost, high efficiency, and the ability to achieve various transmission ratios Disadvantage of spur gears: high noise

What is a helical gear

Helical gears are not entirely helical gears. It should be said that helical gears are the meshing mode of two helical gears, distinguished by their different directions of transmitting force in space. Ordinary spur gears engage simultaneously along the tooth width, resulting in impact vibration noise and unstable transmission.

Application of helical gears

Helical gears are used to transmit heavy loads between parallel shafts at very high speeds. The following are the applications of helical gears in various products: automotive gearboxes, printing and other machinery, conveyors and elevators, factory automation, etc Advantages of helical gears: Compared with spur gears, they have higher load-bearing capacity and contact ratio, smoother, quieter, and better accuracy level Disadvantages of helical gears: Compared to spur gears, they have lower efficiency and increase the axial thrust on the shaft due to the helical angle

What is a herringbone gear

A helical gear has a lateral force on the shaft. To eliminate this force, a gear is made into a symmetrical and opposite helical gear to eliminate this force. It looks like a herringbone and is abbreviated as a double helical gear.

Application of Herringbone Gear

Used for high load-bearing capacity requirements, such as differentials and heavy machinery. Advantages of herringbone teeth: reduced axial force, smoother transmission and engagement, reduced noise, self centering ability, high load capacity Disadvantages of herringbone teeth: manufacturing difficulties and high costs

Development

In the future, gears are developing towards heavy-duty, high-speed, high-precision, and high-efficiency directions, striving for small size, light weight, long service life, and economic reliability. The development of gear theory and manufacturing technology will further study the tooth damage mechanism of gears, laying the foundation for establishing reliable strength calculation methods, and improving the bearing capacity of gears and extending their lifespan. In order to improve the smoothness of gear operation and increase the contact area of the gear at full load, the bearing capacity of the gear is improved by studying its elastic deformation, manufacturing and installation errors, and temperature field distribution.

Material

The commonly used steels for manufacturing gears include quenched and tempered steel, quenched steel, carburized quenched steel, and nitrided steel. The strength of cast steel is slightly lower than that of forged steel, and it is commonly used for larger gears; Grey cast iron has poor mechanical properties and can be used in light load open gear transmissions; Ductile iron can partially replace steel in manufacturing gears; Plastic gears are mostly used in places with light loads and low noise requirements, and their paired gears are generally made of steel gears with good thermal conductivity.

Quench

Advantages

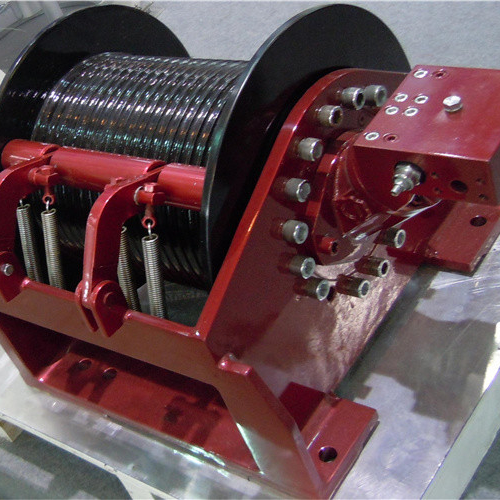

In recent years, our products have been widely used in the fields of offshore platform cranes, oil workover drilling winches, logging rope winding equipment, wall wiping machine winches, helicopter motor winches, and so on. With its high reputation, high-quality products and service system, it has received widespread praise from domestic and foreign customers.

Support and Services

Products Technical Support and Service

We understand how important it is for our customers to have reliable technical support and service for their products. We are here to provide the best possible assistance when it comes to any questions or issues you may have. Our experienced team of experts is available to help you find the best solution for your needs. We offer a variety of technical support options, ranging from troubleshooting and installation to product advice and maintenance. Our technical support team is available 24 hours a day, 7 days a week to answer any questions you may have. In addition to our technical support services, we also provide a wide range of services to keep your products running efficiently and effectively. These services include regular maintenance, repair, and replacement. We can also provide assistance with customization and upgrades if necessary. We strive to provide the best possible technical support and service for our customers. We are committed to keeping your products running smoothly and efficiently. If you have any questions or issues, please do not hesitate to contact us. Our team of experts is here to help.

Packing and Shipping

1.Each product is packed in a strong wooden boxes. 2.The box is labelled with the product details, such as the model number, and other relevant information. 3.We use reliable shipping providers to ensure that our products reach their destination safely and on time.

FAQ

What products do you produce? Our main products include various types of winches, LBS groove drum, LBS sleeves, spooling device winch, petroleum drilling rig winch, trailer mounted pumping unit, crane winch, fifth wheel, Herringbone Gear,etc., What are the areas of application for your products? Products are widely used in offshore platforms, ships, mines, petroleum, coal, ports, terminals, geological exploration, environmental protection, engineering machinery and other heavy machinery. What technical parameters do customers need to provide? 1. Drum diameter: 2. Width between flanges: 3. Rope or cable diameter: 4. Length of rope or cable to be accommodated: 5. Distance to fixed sheave and position between flanges: 6. Direction of wire rope entry: 7. Outside diameter of flanges: 8. Maximum operating load on rope or cable: 9. Type of rope entry through flange or Through barrel: 10. Material and requirements of the drum 11. A detailed drawing of the drum if possible: 12. Any Further Information Can I get a good price? Our products are reasonably priced to be cost-effective. Please send your inquiry to jzjxzz@LBS-china.com, or call +86-311-80761996, and we will reply to your request within 24 hours. How shall I pay? T / T and L / C payments are workable for us. How long does the delivery take from you? Delivery date depends on the model, specification and quantity required. When we make a quotation, we will separately state the delivery date. If you want an earlier delivery, we will try to make shift. How will the goods be packed? Our products are generally packed in wooden cases. How long is the warranty? The warranty starts from the date of BL (AWB) and lasts for 12 months. Do you provide on-site installation and commissioning services? We can provide on-site installation and commissioning services according to your requirements. Details and pricing of the services will be subject to the specially signed foreign technical service contract. If the product fails, how should we do? When failure occurs, please send a description of the failure in words and pictures to us. We will respond within 24 hours after receipt of your notice, and give solution proposals within 48 hours.

Write your message here and send it to us