Winch 3 Tons (Drum) Steel Drum Winch with Spooling Device?

3‑Ton Steel Drum Anchor Winch: Real-World Notes from the Field

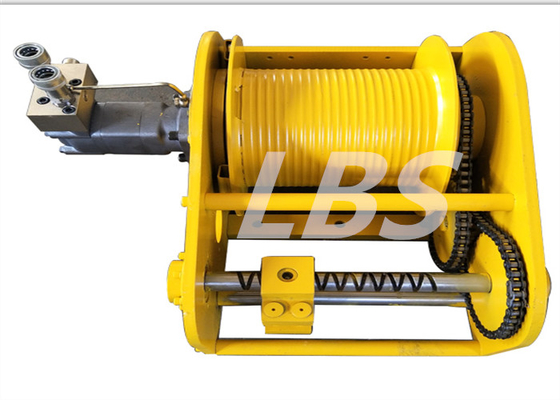

If you lift, pull, or position heavy kit all day, you quickly learn which winches just get on with the job. The Winch 3 Tons (Drum) Steel Drum Winch Standard Anchor Winch With Spooling Device is one of those. It’s a grooved-drum workhorse you’ll see on sites, docks, even small barges. Many customers say they pick it for the tidy layer-by-layer spooling and the fact it’s not fussy about weather.

What’s trending in winches right now

A few things are shaping specs this year: safer control logic, better line management (level wind/ Lebus-style grooving), and higher corrosion resistance for mixed onshore/offshore duty. Actually, even small 3‑ton units are getting optional tension sensors and remote HMI. It seems that “smart and sealed” is the theme.

Key specifications (typical build)

| Rated line pull | 3 t (≈29.4 kN) |

| Drum type | Grooved steel drum with level-wind spooling device |

| Drive | Electric or hydraulic (customer choice) |

| Rope capacity | up to ≈200–300 m at Ø12–14 mm (real-world use may vary) |

| Line speed | ≈10–25 m/min (config-dependent) |

| Brake | Fail‑safe spring-applied, hydraulic/electric release disc brake |

| Protection | Motor IP55/IP65; marine epoxy coating system C4–C5 |

| Controls | Local pendant, radio, or panel with E‑stop and overload |

| Certs (on request) | CE/UKCA; DNV/ABS project compliance |

How it’s built (short version)

Materials: S355 or equivalent welded steel drum and frame; quenched-and-tempered gear steel; sealed bearings; epoxy/polyurethane paint stack. Methods: CNC grooving for even rope lay; stress‑relieved weldments; dynamic balance on drums; factory pre‑tension spooling. Testing standards: EN 14492‑1 for power winches; ISO 4309 for rope handling/inspection; motors to IEC 60034.

Typical factory tests include 125% overload pull for 10 minutes, brake holding at 150% of rated load, and function tests (limit switches, E‑stop). Service life? With correct lubrication and rope inspections, 8–12 years is common; I’ve seen longer in light‑duty forestry.

Where it works best

Construction lifts and drags, small anchor handling on barges, gate operations in water conservancy projects, forestry skidding, and mine maintenance. To be honest, the tidy spooling shines when deck space is tight and rope damage is expensive.

Real customer snapshots

- River barrage: two units synchronized to position stop‑logs; operators liked the smooth low‑speed control.

- Hillside telecom site: hydraulic drive chosen for remote reliability; “set‑and‑forget” comment from the crew.

- Nearshore mooring: upgraded to C5‑M coating; after 14 months, only touch‑ups needed—surprisingly low wear.

Vendor comparison (at a glance)

| Vendor | Lead time | Certs/Compliance | Customization | Notes |

|---|---|---|---|---|

| LBS, Shijiazhuang (origin: NO.688 Zhongshan Rd.) | ≈4–8 weeks | EN 14492‑1, CE; DNV/ABS on request | High: drum, motor, controls, coating | Strong grooving and spooling device package |

| Vendor B (EU) | 6–10 weeks | EN/CE; IECEx options | Medium | Premium pricing; excellent manuals |

| Vendor C (US) | 8–12 weeks | UL/CE; ABS options | High | Great support; higher TCO |

Customization and options

Need hydraulic drive? Specific rope diameter or larger flange? Remote radio with PLC interlocks, load cell, or painted to C5‑M? That’s routine. The Winch 3 Tons (Drum) Steel Drum Winch Standard Anchor Winch With Spooling Device can be supplied with spark‑resistant features for certain zones (check your hazardous area classification first).

Final take

The Winch 3 Tons (Drum) Steel Drum Winch Standard Anchor Winch With Spooling Device is a solid fit when you want orderly rope management, honest 3‑ton pull, and straightforward maintenance. Not flashy—just dependable. I guess that’s why site supervisors keep reordering them.

References

- EN 14492‑1: Power driven winches and hoists – Winches (CEN). https://standards.cen.eu

- ISO 4309: Cranes – Wire ropes – Care and maintenance, inspection and discard. https://www.iso.org

- IEC 60034: Rotating electrical machines (motor performance/protection). https://webstore.iec.ch

- DNV-ST-E407: Lifting Appliances (offshore project compliance). https://www.dnv.com

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025