Mechanical Drum Winch: High Torque, Durable—Why Buy?

mechanical drum winch,buy mechanical drum winch is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of lifting and transportation equipment. This article explores how Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- mechanical drum winch,buy mechanical drum winch Overview

- Benefits & Use Cases of mechanical drum winch,buy mechanical drum winch in Manufacturing of lifting and transportation equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on mechanical drum winch,buy mechanical drum winch from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

mechanical drum winch,buy mechanical drum winch Overview

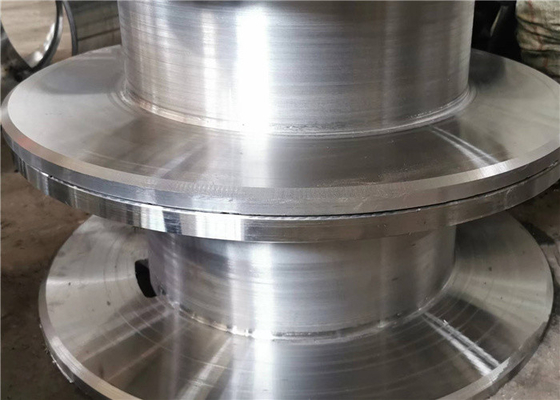

A mechanical drum winch is the core winding component in lifting and transportation equipment, converting motor or engine torque into controlled line pull via a grooved cylindrical drum. In the General equipment manufacturing industry, it underpins critical functions in cranes, hoists, towing systems, and material handling lines where consistent rope spooling, dependable braking, and long service life directly affect uptime and safety.

Engineered drums from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. are typically fabricated from robust steels such as Q355B and can be supplied with precision-machined Lebus-style grooving matched to rope diameter and lay direction to ensure even multi-layer winding. Key configurable parameters include drum diameter and barrel length, flange height, groove pitch and lead, shaft/bearing interfaces, surface treatment, and integration provisions for brakes, gearboxes, and couplings. For heavy-duty use, options such as replaceable grooving sleeves, induction-hardened wear surfaces, and corrosion-resistant coatings are available. As a reliable manufacturer serving the Manufacturing of lifting and transportation equipment segment, the company delivers custom and standard drums that meet demanding alignment, balance, and NDT quality requirements, supporting OEMs and retrofit projects worldwide.

Benefits & Use Cases of mechanical drum winch,buy mechanical drum winch in Manufacturing of lifting and transportation equipment

Manufacturers of cranes, winches, capstans, and specialized transport systems depend on mechanical drum winches for high line-pull stability and predictable rope behavior. Typical applications include mobile and tower cranes, shipboard and offshore deck machinery, mining and construction hoists, conveyor take-up systems, utility cable pulling, and factory floor positioning/rigging stations. Precision grooving enhances rope layering across multiple wraps, minimizing crossovers and crushing, which reduces rope wear and extends inspection intervals.

Competitive advantages of Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. include engineered grooving solutions that maintain constant fleet-angle tolerance, improved line pull per layer, and smoother payout/takeup at varying speeds. The drums can be supplied as single or double drum assemblies, with integration readiness for hydraulic or electric drives, fail-safe braking, and torque monitoring. Heavy-wall construction, optimized weld procedures, and CNC machining deliver dimensional accuracy and balance for vibration-free operation. For B2B decision makers aiming to buy mechanical drum winch assemblies that shorten commissioning time, Junzhong’s application engineering, drawings support, and fast sampling help accelerate OEM development while reducing risk.

Cost, Maintenance & User Experience

Total cost of ownership for a mechanical drum winch is determined by more than purchase price. Rope life, maintenance intervals, downtime, and integration complexity can outweigh initial savings. Precision-grooved drums from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. help lower TCO by reducing rope damage and the frequency of changeouts—an immediate benefit in high-duty cycles. Options like replaceable grooving sleeves limit overhaul costs to wear surfaces rather than the entire drum, while standardized bearings and seals simplify spare parts stocking.

Maintenance best practices include scheduled inspections of groove wear, rope seating, flange integrity, bearing temperature, and brake function; proper lubrication; and adherence to rope installation procedures (pre-tensioning and break-in). Users in the General equipment manufacturing industry report smoother spooling, fewer line shocks, and more consistent line pull after switching to engineered-groove drums, resulting in measurable reductions in unplanned stoppages. In many cases, ROI is realized through longer rope lifecycles and reduced operator intervention, together with improved safety margins and audit readiness.

Sustainability & Market Trends in manufacturing

Sustainability priorities in manufacturing emphasize lifecycle performance, resource efficiency, and safety. A well-designed mechanical drum winch supports these goals by extending wire rope service life (less scrap), enabling safer operations (lower incident risk), and allowing refurbishment via sleeves rather than full drum replacement (less material use). Material traceability, optimized machining to reduce waste, and durable coatings contribute to lower environmental impacts over the equipment’s lifetime.

Market trends point to higher payloads with tighter safety factors, greater electrification, and the adoption of smart sensors for condition monitoring. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. supports these shifts with engineering that accommodates torque/line-speed feedback devices, precision tolerances for high-efficiency drivetrains, and configurations suitable for both electric and hydraulic systems. For B2B teams evaluating how to buy mechanical drum winch solutions aligned with future-ready manufacturing, Junzhong’s focus on design-for-maintainability and upgrade paths (e.g., sleeves, surface treatments, and instrumentation provisions) offers a pragmatic route to meeting performance and sustainability KPIs simultaneously.

Conclusion on mechanical drum winch,buy mechanical drum winch from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

A mechanical drum winch is central to safe, efficient lifting and transportation equipment. By combining robust materials, precision grooving, and integration-ready design, Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. delivers durable, high-value solutions that reduce downtime, extend rope life, and improve ROI for OEMs and plant operators. If you plan to buy mechanical drum winch assemblies tailored to demanding applications, partner with a manufacturer who understands your duty cycle and compliance needs.

Contact us: email: lbswinch@lebus.com.cn

Visit our website: https://www.lbswinch.com

Explore the product: Product page

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025