Reliable 3 Ton Steel Drum Anchor Winch with Spooling Device

Introduction to Advanced Drum Winch Technology

In demanding industrial and marine applications, the reliability and performance of hoisting and pulling equipment are paramount. The Winch 3 Tons (Drum) Steel Drum Winch Standard Anchor Winch With Spooling Device represents a critical advancement in material handling solutions. Engineered for robust performance and operational efficiency, this industrial-grade winch is designed to meet stringent requirements across diverse sectors. Its integrated spooling device ensures precise wire rope management, significantly extending rope life and enhancing operational safety by preventing overwrapping and uneven layering. This article delves into the technical intricacies, application versatility, and strategic advantages of this essential piece of equipment for B2B decision-makers.

Focusing on key aspects such as manufacturing precision, adherence to international standards, and real-world performance, we aim to provide a comprehensive overview that highlights its value proposition in scenarios demanding dependable load handling and anchoring capabilities.

Current Industry Trends in Winch Technology

The industrial winch market is currently shaped by several transformative trends. Firstly, there's a strong push towards enhanced automation and intelligent control systems. Modern winches, including the Winch 3 Tons (Drum) Steel Drum Winch Standard Anchor Winch With Spooling Device, are increasingly incorporating PLC-based controls, remote operation capabilities, and advanced sensor technology for real-time load monitoring and predictive maintenance. This not only boosts operational efficiency but also significantly improves safety protocols by minimizing human intervention in hazardous environments.

Secondly, sustainability and energy efficiency are driving innovation. Manufacturers are developing more energy-efficient motors (e.g., IE3/IE4 efficiency classes), regenerative braking systems, and lightweight yet high-strength materials to reduce operational costs and environmental impact. The integration of variable frequency drives (VFDs) is also becoming standard, allowing for precise speed control and further energy savings.

Finally, customization and modularity are gaining traction. Industries require winches tailored to specific environmental conditions, load capacities, and operational footprints. Suppliers offering modular designs and extensive customization options, from specialized coatings for corrosion resistance to integrated anchoring systems, are better positioned to meet diverse client needs. The demand for winches capable of operating reliably in extreme conditions, such as high salinity marine environments or corrosive chemical plants, further emphasizes the need for specialized material selection and robust design.

Technical Specifications and Parameters

The performance and reliability of any industrial winch are directly tied to its technical specifications. The Winch 3 Tons (Drum) Steel Drum Winch Standard Anchor Winch With Spooling Device is engineered with precise parameters to ensure optimal operation under challenging conditions. Key components include a robust steel drum, high-efficiency gearbox, and a powerful electric motor, all designed for long service life and minimal maintenance.

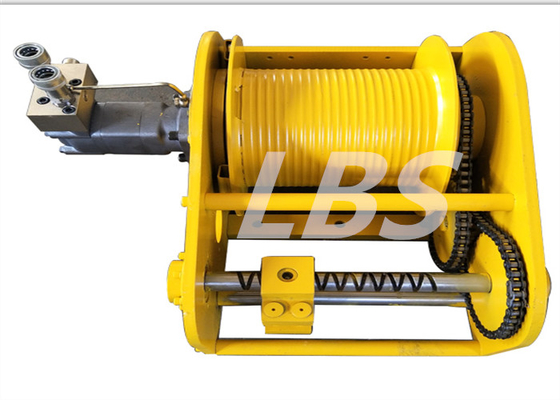

Figure 1: Illustration of a robust steel drum winch.

| Parameter | Value/Description |

|---|---|

| Rated Pulling Capacity | 3 Tons (30 kN) |

| Drum Diameter | Φ250 mm |

| Rope Capacity (Wire Rope) | Φ14 mm x 200 m (Standard) |

| Working Speed | 5-12 m/min (Adjustable via VFD) |

| Motor Power | 7.5 kW - 11 kW (Depending on application) |

| Gearbox Type | Planetary Gearbox / Worm Gear (High-efficiency, low noise) |

| Braking System | Electro-hydraulic failsafe brake with manual release |

| Spooling Device | Integrated automatic diamond screw type for even rope layering |

| Power Supply | 3 Phase, 380V/50Hz (Customizable) |

| Control System | Local pendant control, optional wireless remote, PLC integration |

| Material | High-strength alloy steel frame, cast steel drum, marine-grade coatings |

| Operating Temperature | -20°C to +45°C |

| Compliance | ISO 9001, CE, DNV-GL (Optional marine certification) |

These specifications highlight the winch's capability for heavy-duty, continuous operation, ensuring both safety and efficiency in critical lifting and anchoring tasks. The inclusion of a robust spooling device is crucial for maintaining rope integrity and preventing operational issues often associated with uneven rope winding.

Manufacturing Process Flow and Quality Assurance

The production of a high-performance industrial winch like the Winch 3 Tons (Drum) Steel Drum Winch Standard Anchor Winch With Spooling Device demands a meticulously controlled manufacturing process, adhering to stringent quality standards. This ensures durability, operational safety, and an extended service life in demanding environments like petrochemical, metallurgy, and water supply & drainage.

Schematic Manufacturing Steps:

- Material Selection & Preparation: High-grade alloy steel (e.g., Q345B, S355J2) is selected for structural components and drum. Critical parts like gears and shafts use hardened carbon steel or chromium-molybdenum steel. All incoming materials undergo spectral analysis and ultrasonic flaw detection to ensure compliance with ASTM or EN standards.

- Casting/Forging of Components: The drum is typically cast from high-strength steel or fabricated by welding thick steel plates, followed by stress relief annealing. Gear blanks and shafts are forged for superior grain structure and mechanical properties, then normalized.

- CNC Machining: Precision machining is critical for drum surfaces, gear teeth, shaft dimensions, and mounting interfaces. Advanced CNC lathes and milling machines ensure tight tolerances (e.g., IT6-IT7 for critical dimensions) and surface finishes, reducing wear and improving operational smoothness. This is crucial for the integrated spooling device's accuracy.

- Heat Treatment: Gears and pinions undergo case hardening (carburizing and quenching) or induction hardening to achieve high surface hardness (HRC 55-60) while maintaining a tough core, enhancing wear resistance and load-bearing capacity. Shafts are often tempered for optimal strength and ductility.

- Welding & Fabrication: Structural frames and base plates are precision-welded using techniques like submerged arc welding (SAW) or shielded metal arc welding (SMAW) by certified welders (e.g., AWS D1.1, ISO 9606). Welds undergo non-destructive testing (NDT) such as magnetic particle inspection (MPI) or radiographic testing (RT).

- Surface Treatment & Painting: Components are sandblasted to SA 2.5 standard, followed by multiple coats of industrial-grade primer and topcoat. For corrosive environments, specialized epoxy or polyurethane coatings offer superior corrosion resistance, extending the winch's service life, particularly relevant in marine or chemical processing applications. This step contributes to energy saving by reducing friction.

- Assembly: All sub-assemblies (gearbox, motor, brake, spooling device) are carefully integrated onto the main frame. Bearings, seals, and fasteners are installed according to engineering specifications.

-

Testing & Quality Control:

- No-Load Run Test: Verification of motor function, brake engagement, and spooling device operation.

- Rated Load Test: The winch is tested at its full rated capacity for a specified duration to verify pulling speed, motor current, and temperature rise, as per ISO 4301 or ANSI B30.7 standards.

- Overload Test: A 125% overload test is typically conducted to ensure safety margins and structural integrity.

- Noise & Vibration Analysis: To ensure comfortable operation and structural health.

- Functional Test of Spooling Device: Verifying even rope layering under load.

- Final Inspection & Documentation: A comprehensive final inspection, including dimensional checks, paint finish, and control system functionality, is performed. Certification documents, operation manuals, and maintenance guides are prepared.

Figure 2: Winch components undergoing quality inspection.

The rigorous adherence to international manufacturing and testing standards (e.g., ISO 9001 for quality management, ISO 4301 for lifting appliances, ANSI B30.7 for base-mounted drum hoists) ensures that each unit delivers consistent performance and a projected service life exceeding 20 years with proper maintenance. Advantages include enhanced energy saving through efficient gearbox designs and corrosion resistance through advanced surface treatments, making it ideal for demanding industries.

Versatile Application Scenarios

The robust design and precision engineering of the Winch 3 Tons (Drum) Steel Drum Winch Standard Anchor Winch With Spooling Device make it indispensable across a multitude of industrial and marine applications. Its 3-ton capacity, combined with precise rope management provided by the spooling device, ensures safe and efficient operation in critical tasks.

Figure 3: Winch deployed in a construction setting.

- Construction & Infrastructure: Ideal for lifting heavy building materials, pulling structural components into place, or operating pile drivers. Its compact footprint allows for integration into various site setups. The spooling device prevents rope damage during repetitive lifting cycles common in construction.

- Marine & Offshore Operations: Serving as a standard anchor winch on smaller vessels, barges, or offshore platforms. It facilitates anchor handling, mooring operations, and deployment/recovery of research equipment. The corrosion-resistant design ensures longevity in saltwater environments.

- Mining & Metallurgy: Used for pulling ore carts, conveyor belt tensioning, or material handling in processing plants. Its robust construction can withstand abrasive conditions and continuous operation.

- Petrochemical & Energy: Essential for pipeline installation, equipment positioning, and maintenance tasks within refineries or power plants. The explosion-proof motor options and precise control are critical in these sensitive environments.

- Water Treatment & Drainage: Employed for lifting sluice gates, managing screens, or positioning pumps in water infrastructure projects. The ability to operate reliably in humid and potentially corrosive conditions is a significant advantage.

- Manufacturing & Warehousing: Utilized for heavy equipment relocation, assembly line assistance, or automated storage and retrieval systems where precise, controlled movement of heavy loads is required.

The versatility of this winch is underscored by its adaptability to various power sources (electric, hydraulic, pneumatic) and control configurations, making it a valuable asset for operations requiring reliable, powerful, and precise pulling or lifting capabilities.

Technical Advantages and Performance Benefits

The inherent technical advantages of this 3-ton steel drum winch stem from its comprehensive design and adherence to high engineering standards. These benefits translate directly into operational efficiency, safety, and reduced total cost of ownership for industrial users.

- Integrated Spooling Device: This feature is a significant differentiator. It ensures the wire rope is always evenly layered on the drum, preventing cross-winding, crushing, and premature wear. This extends wire rope service life by up to 30%, reduces downtime for rope replacement, and significantly enhances operational safety by preventing unexpected rope failures.

- High-Efficiency Drivetrain: Equipped with robust helical or planetary gearboxes, the winch achieves superior mechanical efficiency (typically >90%). This minimizes power loss, resulting in significant energy saving compared to older worm gear designs, especially beneficial in applications with frequent starts and stops.

- Corrosion Resistance: Utilizing marine-grade paints and coatings, along with options for stainless steel components or hot-dip galvanization, the winch exhibits excellent corrosion resistance. This is crucial for longevity in harsh environments such as coastal areas, chemical plants, or water treatment facilities, drastically reducing maintenance and replacement costs.

- Precision Control: The option for Variable Frequency Drives (VFDs) provides smooth acceleration and deceleration, precise speed control, and accurate load positioning. This not only enhances safety by preventing shock loads but also allows for delicate handling of sensitive materials.

- Robust Braking System: Featuring an electro-hydraulic failsafe brake, the system automatically engages upon power loss, ensuring the load is securely held. This critical safety feature provides peace of mind in high-risk lifting or anchoring operations.

- Durable Construction: Built with heavy-duty steel frames and components designed for continuous duty (e.g., FEM 1Am or ISO M5 duty cycles), the winch is engineered for maximum durability and minimal deflection under full load, ensuring a long operational life.

These technical advantages collectively position the product as a superior choice for industries that demand unwavering performance, maximum safety, and long-term cost-effectiveness from their material handling equipment.

Vendor Comparison: Why Choose Our 3-Ton Drum Winch

When evaluating industrial winches, distinguishing between vendors is critical. While many suppliers offer 3-ton capacity winches, the true value lies in design integrity, component quality, after-sales support, and customization capabilities. Below is a comparison highlighting key differentiators for the Winch 3 Tons (Drum) Steel Drum Winch Standard Anchor Winch With Spooling Device against typical market alternatives.

| Feature | Our 3-Ton Drum Winch | Typical Market Alternative |

|---|---|---|

| Spooling Device | Integrated automatic diamond screw type (Standard) | Manual or optional external spooler (Higher cost, less efficient) |

| Motor Efficiency | IE3/IE4 standard, VFD compatible for energy saving | IE1/IE2 standard, fixed speed, higher energy consumption |

| Corrosion Protection | Multi-layer epoxy/polyurethane marine-grade coating, optional galvanization | Standard industrial paint, limited protection in harsh environments |

| Braking System | Electro-hydraulic failsafe brake with over-torque protection | Mechanical shoe brake or simple electric brake, less precise |

| Gearbox Design | Robust planetary or helical gears, sealed for life lubrication | Worm gear or open gear systems, higher maintenance, lower efficiency |

| Certifications | ISO 9001, CE, optional DNV-GL, ABS, BV | Basic CE, sometimes no specific certifications |

| Customization | Extensive options for capacity, speed, drum size, control, and environment adaptation | Limited customization, standard models only |

| Service Life | Designed for 20+ years with proper maintenance | Typically 10-15 years, higher wear and tear |

This comparison demonstrates our commitment to delivering superior quality, enhanced safety, and long-term value. Our investment in advanced features like the integrated spooling device and high-efficiency components translates into lower operational costs and greater reliability, making it a strategic choice for discerning industrial clients.

Customized Solutions and Tailored Engineering

Recognizing that no two industrial operations are identical, we specialize in providing customized solutions for the Winch 3 Tons (Drum) Steel Drum Winch Standard Anchor Winch With Spooling Device. Our engineering team works closely with clients to modify standard designs or create bespoke winches that precisely match specific operational demands, environmental conditions, and regulatory requirements.

- Capacity and Speed Adjustments: While the standard is 3 tons, we can adjust line pull, speed, and rope capacity to suit unique project parameters, optimizing for either higher speed at lighter loads or maximum pull force.

- Environmental Adaptations: For extreme temperatures, corrosive atmospheres (e.g., chemical processing), or explosive environments (e.g., oil & gas), we offer specialized materials, coatings, and ATEX-certified components. This includes sealed enclosures, anti-condensation heaters, and marine-grade protective systems.

- Control System Integration: From advanced PLC-based automation for integration with existing SCADA systems to explosion-proof remote controls and specialized HMI interfaces, our control systems are designed for seamless operation and enhanced safety.

- Drum Design Modifications: Options include split drums for multiple rope lines, grooved drums for improved rope lay, or larger drum diameters for increased rope capacity.

- Power Source Versatility: While primarily electric, we can configure winches for hydraulic or pneumatic power, catering to sites where electrical supply is limited or hazardous.

Our engineering expertise ensures that every customized winch retains the core reliability and performance characteristics expected, while delivering precise functionality for the client's unique challenges.

Application Case Studies & Customer Experience

Our commitment to quality and tailored solutions is best exemplified through real-world applications. The Winch 3 Tons (Drum) Steel Drum Winch Standard Anchor Winch With Spooling Device has proven its capabilities in diverse and demanding environments, earning trust from leading industrial partners.

Case Study 1: Offshore Platform Maintenance (Southeast Asia)

A major offshore energy company required a robust anchoring solution for their maintenance barge operating in corrosive tropical waters. Our customized 3-ton electric winch, equipped with a specialized marine-grade coating, DNV-GL certification, and an integrated auto-spooling device, was chosen. The client reported a 15% reduction in wire rope replacement frequency due to the efficient spooling, and zero downtime attributed to winch malfunction over 3 years of continuous operation. The operational manager praised the winch’s reliability and the significant cost savings on maintenance.

Figure 4: Winch in an offshore or heavy-duty industrial setting.

Case Study 2: Municipal Water Treatment Plant Upgrade (Europe)

A large municipal water treatment facility needed to replace aging winches used for controlling sluice gates and lifting heavy filter modules. The environment presented challenges with constant humidity and exposure to treated water chemicals. We supplied a series of 3-ton winches with IP67-rated motors, corrosion-resistant components, and VFD-controlled precise speed adjustments. The VFD integration led to an estimated 20% energy saving compared to their previous equipment, and the precise control significantly reduced the risk of gate damage during opening and closing cycles. The facility director noted the winches' "unwavering performance and enhanced safety features."

Case Study 3: Bridge Construction Project (North America)

For a complex bridge construction project involving the precise positioning of pre-fabricated sections, our winches were deployed as part of a synchronized lifting system. The integrated spooling device ensured smooth and reliable rope management, crucial for maintaining synchronization and preventing snags during critical lifts. The robust design endured continuous, heavy-duty cycles, contributing to the project's adherence to a tight schedule. The site supervisor commended the winches for their "reliability under pressure and critical role in achieving high-precision placement."

Trustworthiness: FAQ, Lead Time, Warranty & Support

Building and maintaining trust with our B2B clients is foundational. We provide clear commitments regarding product quality, delivery, and post-sale support for every Winch 3 Tons (Drum) Steel Drum Winch Standard Anchor Winch With Spooling Device.

Frequently Asked Questions (FAQ)

-

Q: What is the typical lead time for a 3-ton drum winch?

A: Standard models typically have a lead time of 4-6 weeks from order confirmation. Customized solutions may require 8-12 weeks depending on complexity and specific component sourcing. Expedited options are available upon request. -

Q: What kind of warranty is offered?

A: We provide a comprehensive 12-month warranty on all mechanical and electrical components from the date of commissioning or 18 months from delivery, whichever comes first. Extended warranty packages are available. -

Q: Can the winch be adapted for hazardous environments?

A: Yes, we offer ATEX-certified components, explosion-proof motors, and specialized enclosures for operation in Zone 1 and Zone 2 hazardous areas. Please specify your requirements for tailored solutions. -

Q: What after-sales support is available?

A: Our global support network offers installation supervision, commissioning assistance, operator training, spare parts supply, and remote technical support. On-site service is available through our certified service partners worldwide.

Lead Time & Fulfillment

Our streamlined production process and robust supply chain enable efficient order fulfillment. We maintain a stock of critical components to minimize delays, ensuring that standard units can be dispatched within competitive lead times. For custom orders, a detailed project timeline with milestones is provided, ensuring transparency throughout the manufacturing and delivery process.

Warranty Commitments

Our warranty reflects our confidence in the superior quality and craftsmanship of our winches. It covers defects in material and workmanship under normal operating conditions. Our dedicated warranty team ensures prompt resolution of any covered issues, minimizing operational disruption for our clients.

Figure 5: Professional support and service team.

Customer Support & After-Sales Service

Our commitment extends beyond delivery. We offer comprehensive after-sales support, including readily available spare parts, detailed technical documentation, and access to skilled engineers for troubleshooting and maintenance guidance. Our global network of service partners ensures that expert assistance is always within reach, guaranteeing the continuous optimal performance and longevity of your equipment.

Conclusion

The Winch 3 Tons (Drum) Steel Drum Winch Standard Anchor Winch With Spooling Device stands as a testament to advanced engineering and manufacturing excellence. Its robust design, precise control, integrated spooling mechanism, and adaptability to diverse industrial environments make it an indispensable asset. By offering unparalleled reliability, safety, and long-term cost-effectiveness, this winch is engineered to meet and exceed the rigorous demands of modern industrial operations, reinforcing our position as a trusted partner in heavy-duty material handling.

References

- International Organization for Standardization. ISO 4301-1: Cranes – Classification – Part 1: General.

- American Society of Mechanical Engineers. ASME B30.7: Base-Mounted Drum Hoists.

- European Federation of Materials Handling. FEM 1.001: Rules for the design of hoisting appliances.

- DNV-GL Standards for Certification No. 2.22 Lifting Appliances.

- National Institute for Occupational Safety and Health (NIOSH). Engineering Controls for Preventing Wire Rope Failures.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025