Powerful Dual Drum Winch: High Mast & Mooring Solutions

Industry Trends and Market Dynamics for Advanced Winching Systems

The global demand for high-performance winching solutions, particularly in marine, offshore, and heavy-lift applications, continues to evolve rapidly. A key area of innovation and increasing adoption is the dual drum winch. This advanced equipment is becoming indispensable for operations requiring precision, high lifting capacity, and enhanced safety protocols. Market analyses indicate a Compound Annual Growth Rate (CAGR) of approximately 4.5% for the global winching systems market, reaching an estimated USD 15.2 billion by 2028, driven by expanding infrastructure projects, energy exploration, and maritime logistics.

Key trends include the integration of smart technologies, such as IoT for predictive maintenance and remote diagnostics, and advanced automation for single-person operation. There's also a significant push towards energy efficiency, with variable frequency drives (VFDs) becoming standard to optimize power consumption and reduce operational costs. Furthermore, the emphasis on environmental compliance, particularly in marine applications, is driving innovation in hydraulic and electric systems to minimize noise and pollution. The demand for robust, corrosion-resistant systems capable of operating in harsh environments, from subsea installations to high-altitude construction, further underscores the importance of meticulously engineered winches.

Detailed Manufacturing Process of a High-Performance Dual Drum Winch

The production of a dual drum winch, such as the Marine Platform Ship Cranes Double Fold Line Rope Groove Drum, is a sophisticated multi-stage process that adheres to stringent engineering standards to ensure durability, reliability, and peak performance in demanding operational environments. Our manufacturing approach integrates cutting-edge technology with rigorous quality control, from raw material selection to final assembly and testing.

Process Flow Schematic:

- 1. Material Selection & Procurement: High-grade alloy steels (e.g., Q345B, S355J2, 42CrMo) are meticulously selected for drum bodies, shafts, and structural components, ensuring superior tensile strength, yield strength, and fatigue resistance. Critical components like gears and bearings utilize specialized heat-treated steels for enhanced wear resistance. Materials for marine applications also incorporate corrosion-resistant coatings or stainless steel alloys.

- 2. Component Fabrication (Casting & Forging):

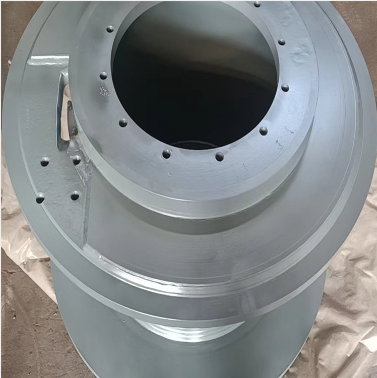

- Drum Blanks: Large drum blanks are often cast from high-strength ductile iron or steel, then precision-machined. For highly stressed applications, forged steel drums offer superior grain structure and mechanical properties.

- Shafts & Gears: Shafts are typically forged from alloy steel to achieve optimal strength-to-weight ratios and then heat-treated. Gears undergo precision forging followed by carburizing or nitriding to achieve a hard wear surface with a tough core.

- 3. Advanced Machining (CNC): All critical components, including drum rope grooves, gear teeth, bearing journals, and mounting surfaces, are subjected to multi-axis CNC machining. This ensures micron-level precision, critical for smooth operation, extended service life, and adherence to tight tolerances specified by standards like ANSI B89.1.5 and ISO 2768. The rope groove profiles (e.g., Lebus or folded line rope grooves for specific Marine Platform Ship Cranes Double Fold Line Rope Groove Drum applications) are precisely cut to optimize rope spooling and minimize wear.

- 4. Surface Treatment & Coating: Components destined for harsh environments undergo specialized surface treatments. This includes shot blasting for surface preparation, followed by multi-layer marine-grade epoxy coatings for superior corrosion resistance, particularly for double drum mooring winch systems. Heat treatments such as induction hardening, carburizing, and quenching are applied to enhance hardness and wear resistance of critical moving parts.

- 5. Assembly & Integration: Skilled technicians assemble the winch components, integrating the hydraulic power unit (HPU) or electric motor, gearbox, brakes (fail-safe disc brakes or band brakes), control systems, and safety features. Each step is documented and inspected.

- 6. Rigorous Testing & Quality Assurance: Every dual drum winch undergoes comprehensive testing:

- Load Testing: Static and dynamic load tests performed at 125% and 110% of the rated working load, respectively, as per ISO 8686-1 and API Spec 2C.

- Brake Performance: Verification of braking force, holding capacity, and emergency stop functionality.

- Functional Testing: Operation under various speed and load conditions, checking motor performance, gearbox efficiency, and control system responsiveness.

- Noise & Vibration Analysis: Ensuring adherence to occupational health and safety standards.

- Non-Destructive Testing (NDT): Ultrasonic testing, magnetic particle inspection, and radiographic inspection for critical welds and castings to detect internal flaws.

- 7. Certification & Documentation: Upon successful completion of all tests, the winch is certified by relevant classification societies such as ABS, DNV-GL, Lloyd's Register, or BV, ensuring compliance with international maritime and industrial safety standards. Comprehensive documentation including operation manuals, maintenance schedules, and material certificates is provided.

The target industries for these robust winches include petrochemical, metallurgy, marine and offshore, mining, water supply & drainage, and general heavy industry. Advantages in typical application scenarios include significant energy saving through efficient power transmission systems, superior corrosion resistance for extended operational life in harsh marine environments, and enhanced safety features like redundant braking systems.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications of a dual drum winch is paramount for B2B decision-makers. Our winches are engineered to deliver exceptional performance, reliability, and safety across a broad spectrum of demanding applications. Below are typical parameters for advanced double drum winch for high mast and marine applications.

Dual Drum Winch Product Specifications Table

| Parameter | Specification Range | Notes |

|---|---|---|

| Rated Line Pull (per drum) | 5 Ton (50 kN) to 300 Ton (3000 kN) | Configurable based on application requirements. |

| Rope Capacity (each drum) | 500 m to 8000 m (depending on rope diameter) | Lebus or Folded Line Rope Groove for optimal spooling. |

| Line Speed (first layer) | 5 m/min to 60 m/min | Variable speed control via VFD or hydraulic system. |

| Power Source | Electric (AC motor, VFD) / Hydraulic / Diesel-Hydraulic | Efficiency class IE3/IE4 motors for electric variants. |

| Braking System | Hydraulically released, spring-applied disc brakes / Band brakes | Redundant safety braking mechanisms, typically >150% static holding. |

| Control System | Local control panel, Remote control (wired/wireless), PLC automation | Integrated load monitoring, emergency stop, spooling synchronization. |

| Operating Temperature | -40°C to +50°C | Special considerations for arctic or tropical environments available. |

| Certifications | ABS, DNV-GL, LR, BV, CCS, RMRS, ISO 9001, CE | Project-specific certifications can be accommodated. |

| Enclosure Protection | IP56 (standard), IP67 (optional) | Suitable for harsh outdoor and marine conditions. |

These parameters are designed to meet the rigorous demands of offshore platforms, research vessels, heavy construction sites, and specialized industrial facilities, ensuring both operational efficiency and a long service life.

Application Scenarios and Technical Advantages

The versatility of a dual drum winch makes it an invaluable asset across numerous heavy-duty industries. Its design allows for independent or synchronized operation of two drums, providing unparalleled flexibility and control for complex lifting and pulling tasks.

Key Application Scenarios:

- Offshore & Marine Operations: Essential for anchor handling, deep-sea mooring, subsea deployment/recovery, and platform tensioning systems. The dual drum configuration enables precise management of mooring lines or complex subsea assets.

- High Mast Lighting Systems: Specifically, a double drum winch for high mast applications is critical for raising and lowering heavy lighting arrays for maintenance. The dual drums ensure balanced lifting, preventing tilting and ensuring stability during operation, which is crucial for safety and system integrity.

- Construction & Infrastructure: Used in bridge construction for cable tensioning, heavy lifting at remote sites, and specialized material handling where synchronized or independent lifting is required for large, unwieldy components.

- Mining & Tunneling: For pulling heavy ore cars, tensioning conveyor belts, or assisting in equipment movement within confined spaces. The robust construction is ideal for harsh subterranean conditions.

- Hydropower & Water Management: Operating spillway gates, dam maintenance, and managing heavy structures in water-related infrastructure.

Technical Advantages:

- Enhanced Safety & Redundancy: With two independent drums, operations can maintain greater control and offer a level of redundancy. If one system experiences an issue, the other can often be used for stabilization or emergency operations. Integrated load limiters and emergency stop functions are standard.

- Precision & Control: Advanced control systems (e.g., PLC-based with human-machine interface HMI) allow for precise speed and tension control on each drum, enabling synchronized or differential operations crucial for complex lifts or line management.

- Increased Efficiency: The ability to perform two tasks simultaneously or to manage two lines independently significantly boosts operational efficiency and reduces project timelines. Features like automatic rope spooling ensure consistent and safe winding.

- Durability & Longevity: Constructed from high-strength materials and featuring robust gearbox designs, these winches are built for continuous heavy-duty operation with minimal maintenance, even in corrosive marine environments.

- Adaptability: Modular design allows for integration with various power sources (electric, hydraulic, diesel), braking systems, and control options, making them highly adaptable to specific project requirements.

Vendor Comparison and Customized Solutions

Selecting the right vendor for a dual drum winch is a critical decision that impacts operational efficiency, safety, and long-term cost of ownership. It goes beyond initial purchase price to encompass reliability, support, and the ability to deliver tailored solutions.

Key Factors in Vendor Comparison:

| Factor | Leading Manufacturers (e.g., LBS Winch, XYZ Corp.) | Other Vendors (e.g., ABC Solutions) |

|---|---|---|

| Product Range & Customization | Extensive standard models; high degree of custom engineering (load, speed, rope capacity, drive type, control systems, marine-grade materials). | Limited standard options; less flexibility for bespoke designs. |

| Quality & Certifications | ISO 9001, CE, ABS, DNV-GL, LR, BV certified; rigorous NDT and load testing. | May meet basic industry standards but lack specific classification society approvals for critical applications. |

| After-Sales Support & Warranty | Global service network, 24/7 technical support, comprehensive spare parts, extended warranties (2-5 years). | Limited regional support, shorter warranties (1 year), potentially delayed spare parts. |

| Technological Innovation | VFD integration, PLC automation, remote diagnostics, energy recovery systems, advanced rope spooling (Lebus/folded line grooves). | Basic hydraulic/electric systems, less emphasis on smart features or energy efficiency. |

| Lead Time & Project Management | Structured project management, clear timelines (typically 12-24 weeks for custom builds), dedicated project engineers. | Variable lead times, less transparent project tracking. |

Customized Solutions for Specific Needs:

Recognizing that no two projects are identical, we specialize in providing highly customized dual drum winch solutions. Our engineering team collaborates closely with clients to develop specifications that precisely match their operational requirements, environmental conditions, and budget constraints. This includes:

- Power System Configuration: Tailoring electric (AC/DC), hydraulic, or diesel-driven systems with specific power outputs and control schemes.

- Rope Management: Custom drum sizes, Lebus or folded line rope grooves (as seen in the Marine Platform Ship Cranes Double Fold Line Rope Groove Drum), and automatic spooling devices optimized for various wire ropes or fiber lines.

- Environmental Adaptations: Specialized coatings for extreme corrosion resistance, heating/cooling systems for hydraulic units in harsh climates (-40°C to +50°C), and explosion-proof (ATEX/IECEx) certifications for hazardous environments.

- Integrated Control & Monitoring: Bespoke PLC/HMI systems with options for remote diagnostics, data logging, real-time tension monitoring, and integration into vessel/platform management systems.

- Footprint & Mounting: Custom base frames and mounting arrangements to fit specific deck layouts or installation spaces, minimizing structural modifications.

Application Case Studies & Customer Experience

Our commitment to delivering reliable and high-performance winching solutions is validated through numerous successful installations and positive client feedback. These case studies highlight the tangible benefits our dual drum winch systems bring to complex projects globally.

Case Study 1: Offshore Platform Mooring System Upgrade

Client: Major International Oil & Gas Producer

Challenge: An aging mooring system on a North Sea exploration platform required an upgrade to meet stricter environmental regulations and enhance operational safety during severe weather conditions. The existing winches lacked the precision for dynamic positioning assistance and required frequent, costly maintenance.

Solution: We supplied two customized 150-ton double drum mooring winch systems, each featuring Lebus rope grooves, integrated tension monitoring, and a fully redundant electro-hydraulic power unit. The PLC-based control system allowed for synchronized pay-out/haul-in across all mooring lines, enhancing station-keeping capabilities.

Outcome: The new winches significantly improved mooring stability, reduced line wear by 30% due to optimized spooling, and decreased maintenance downtime by 40%. The client reported enhanced operational safety and compliance with the latest DNV-GL offshore standards. Lead time for design, manufacturing, and FAT (Factory Acceptance Test) was 20 weeks.

Case Study 2: High Mast Lighting Installation for Port Terminal

Client: Major Seaport Authority

Challenge: The port required a robust and reliable system for maintaining their 30-meter high mast lighting poles. Manual methods were slow and unsafe. Precision and speed were critical for minimizing disruption to port operations during maintenance cycles.

Solution: We provided a series of custom-designed double drum winch for high mast applications, each with a 10-ton capacity, optimized for a compact footprint. These electric winches incorporated automated limit switches and an anti-slack device, ensuring precise and balanced ascent/descent of the heavy lighting rings.

Outcome: The solution dramatically improved the efficiency and safety of high mast maintenance. Operational time for lowering and raising a lighting ring was reduced by 60%, and the precise control eliminated the risk of tilting or entanglement. The client lauded the intuitive control interface and the system's robust performance in a corrosive port environment.

Frequently Asked Questions (FAQ)

- Q1: What is the typical lead time for a custom dual drum winch?

- A1: For standard models with minor modifications, the lead time is typically 12-16 weeks. For highly customized solutions, involving new engineering designs and specific material procurement, the lead time can range from 20-30 weeks. We provide a detailed project schedule upon order confirmation.

- Q2: What warranty is offered on your dual drum winches?

- A2: We provide a comprehensive 24-month warranty on all mechanical and electrical components, starting from the date of commissioning or 30 months from delivery, whichever comes first. Extended warranty options are available upon request.

- Q3: How do you ensure compliance with international maritime standards (e.g., DNV-GL, ABS)?

- A3: Our engineering and manufacturing processes strictly adhere to the requirements of leading classification societies. We maintain active certifications with bodies such as ABS, DNV-GL, Lloyd's Register, and Bureau Veritas. All critical components are traceable, and thorough documentation is provided for class approval and audits.

- Q4: Can your winches operate in hazardous environments (e.g., ATEX zones)?

- A4: Yes, we offer specialized explosion-proof designs certified for operation in ATEX or IECEx zones, typically Zone 1 or Zone 2. These configurations include flameproof enclosures, intrinsically safe control circuits, and non-sparking components to meet strict safety regulations in petrochemical and gas industries.

- Q5: What kind of after-sales support do you provide?

- A5: Our after-sales support includes 24/7 technical assistance, global spare parts supply, on-site commissioning, preventative maintenance contracts, and comprehensive operator training programs. We have a network of service engineers ready to deploy worldwide.

Commitment to Quality, Support, and Timely Fulfillment

Our reputation is built on delivering winching solutions that exceed expectations in performance, longevity, and safety. We understand that for B2B clients, predictability in lead times and robust post-sales support are as crucial as the product itself.

Lead Time & Fulfillment

We operate with transparent project management methodologies. Upon receiving your detailed requirements, our engineering team will provide a comprehensive proposal including technical specifications, a firm quotation, and a detailed project timeline. Our manufacturing facility, leveraging advanced production planning and inventory management, ensures that component procurement and assembly are streamlined to meet agreed-upon delivery schedules. Typical fulfillment for a standard dual drum winch ranges from 12-16 weeks, while highly custom-engineered solutions typically require 20-30 weeks, including design, fabrication, testing, and certification.

Warranty Commitments

Our winches are backed by an industry-leading warranty, reflecting our confidence in their quality and durability. A standard 24-month warranty covers material defects and workmanship. This warranty period can be extended through tailored service agreements, providing clients with peace of mind and protecting their investment over the long term. Each winch undergoes rigorous Factory Acceptance Testing (FAT) to verify performance against contractual specifications before shipment.

Comprehensive Customer Support

Our commitment to our clients extends far beyond the sale. We offer a holistic suite of customer support services designed to maximize the uptime and efficiency of your winching systems:

- 24/7 Technical Hotline: Access to expert engineers for immediate troubleshooting and operational guidance.

- Global Field Service: On-site support for installation, commissioning, preventative maintenance, and emergency repairs by certified technicians.

- Spare Parts Management: A robust inventory system and global distribution network ensure rapid availability of genuine spare parts, minimizing downtime.

- Training Programs: Customized training for operators and maintenance personnel to ensure safe and efficient operation of the winch system.

- Lifecycle Support: Offering upgrades, refurbishments, and end-of-life management services to extend the operational life of your equipment.

References:

- ISO 8686-1: Cranes – Design principles for loads and load combinations – Part 1: General.

- API Spec 2C: Specification for Offshore Pedestal-Mounted Cranes. American Petroleum Institute.

- DNV-GL Offshore Standards, OS-E401: Design of Offshore and Platform Lifting Appliances.

- ABS Rules for Building and Classing Offshore Support Vessels. American Bureau of Shipping.

- Journal of Ocean Engineering and Science, "Advancements in Marine Mooring Systems Technology," Vol. 8, Issue 3, 2022.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025