Powerful Double Drum Winches - Electric & Compact 120V

Mastering Industrial Operations with Advanced Winch Systems

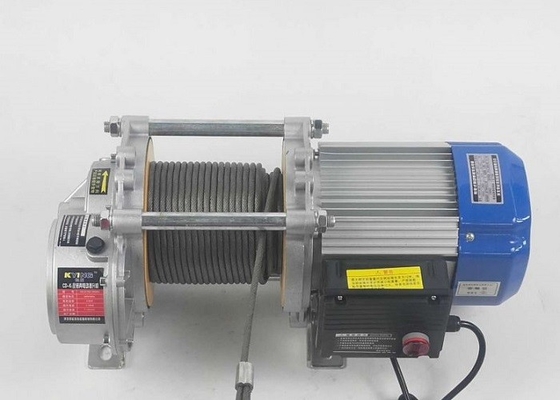

In today's demanding industrial landscape, the efficiency and reliability of heavy-lifting and pulling equipment are paramount. Among the most critical components are double drum winches, versatile machines engineered for precision and power in diverse applications. These robust systems, exemplified by our Electric Winch Drum Winch 12V Transfer Gear Double Drum Winches, offer unparalleled control and operational flexibility compared to their single-drum counterparts. Their design ensures balanced load distribution and enhanced safety, making them indispensable across various sectors that require synchronous or independent rope management.

Our expertise in specialized industrial equipment ensures that these winches are not merely tools but strategic assets, capable of optimizing complex material handling operations. With a focus on durability, performance, and user-centric design, our solutions meet the rigorous demands of modern industrial environments, ensuring seamless integration and long-term value.

Industry Trends and Technological Evolution

The industrial winch market is currently undergoing significant transformation, driven by demands for increased automation, energy efficiency, and enhanced safety features. Key trends include the integration of smart control systems, remote monitoring capabilities, and the development of more compact yet powerful designs. The emergence of specialized solutions, such as the electric winch 120v and small electric winch 120v, addresses the growing need for portable, high-performance winches that can operate effectively in confined spaces or with limited power infrastructure. These advancements facilitate easier deployment and offer considerable flexibility for onsite operations, reducing setup times and operational costs.

Technological leaps in motor efficiency and gear reduction systems are also contributing to the overall performance of double drum winches, allowing for greater pulling capacities with smaller footprints. This evolution is crucial for industries constantly seeking to maximize operational output while minimizing their environmental impact.

Key Technical Parameters and Specifications

Understanding the technical specifications of double drum winches is crucial for optimal selection and deployment. Parameters such as nominal pulling force, rope capacity per drum, motor power, and operating speed directly impact performance and suitability for specific tasks. For instance, the "nominal pulling force" refers to the maximum load the winch can safely lift or pull, typically measured in tons or kilonewtons (kN). "Rope capacity" dictates the maximum length and diameter of the wire rope that can be stored on each drum, a critical factor for long-distance hauls.

Our Electric Winch Drum Winch 12V Transfer Gear Double Drum Winches are designed with precision engineering, ensuring high efficiency and durability. Below is a representative table of common parameters for various configurations of double drum winches, highlighting the versatility available to meet diverse operational needs.

| Parameter | Small-Duty (e.g., small electric winch 120v) | Medium-Duty (e.g., electric winch 120v) | Heavy-Duty |

|---|---|---|---|

| Nominal Pulling Force | 0.5 - 2 tons (5-20 kN) | 3 - 10 tons (30-100 kN) | 15 - 50+ tons (150-500+ kN) |

| Rope Capacity per Drum (Diameter x Length) | Φ6-10mm x 100-200m | Φ12-20mm x 200-500m | Φ24-40mm x 500-1000m+ |

| Motor Power | 0.75 - 3 kW | 5.5 - 30 kW | 37 - 132+ kW |

| Operating Speed | 5 - 15 m/min | 8 - 25 m/min | 10 - 30 m/min |

| Voltage Options | 12V, 24V, 120V AC/DC | 120V, 240V, 400V, 480V AC | 380V, 440V, 690V AC |

| Control System | Push button, Wireless remote | Wired pendant, PLC-controlled, VFD | Advanced PLC with HMI, Remote diagnostics |

Craftsmanship Unveiled: The Manufacturing Process

The production of high-performance double drum winches involves a meticulous multi-stage manufacturing process, ensuring each unit meets stringent quality and performance criteria. It commences with the careful selection of high-grade materials, including robust alloy steels for gears and drums, and corrosion-resistant coatings for external components. Key manufacturing stages include precision casting and forging of critical parts, followed by advanced CNC machining to achieve exact tolerances for gear sets, shafts, and drum surfaces.

Heat treatment processes, such as carburizing and tempering, are applied to enhance the hardness and wear resistance of critical moving parts, significantly extending the product's service life. Each component undergoes rigorous inspection at every stage, adhering to international standards like ISO 9001 and ANSI specifications. This ensures optimal functionality and reliability in demanding environments like petrochemical facilities, metallurgy plants, and water treatment systems. The final assembly includes comprehensive testing of the electrical systems, mechanical integrity, and load-bearing capacity. Our winches are engineered not only for durability but also for energy efficiency and superior corrosion resistance, crucial for challenging industrial applications.

Versatile Application Scenarios and Operational Advantages

The inherent design of double drum winches makes them exceptionally versatile across a multitude of industrial and commercial applications. Their ability to manage two independent or synchronously operating ropes provides distinct advantages in scenarios requiring precision control and sequential pulling or lifting. In construction, they are indispensable for pile driving, structural erection, and the precise positioning of heavy modules. The mining sector utilizes them for shaft sinking, material hoisting, and equipment retrieval from deep underground.

Furthermore, in marine and offshore operations, these winches are critical for mooring, anchor handling, and subsea equipment deployment, where controlled, synchronized movements are paramount for safety and efficiency. Their robust construction and advanced control systems ensure reliable performance even in harsh environmental conditions. The flexibility offered by dual drums allows for complex rigging setups, enhancing operational safety and reducing the need for multiple single-drum units. This multi-functionality translates into significant cost savings and improved project timelines for our clients.

Superior Technical Advantages and Performance Metrics

The technical superiority of our double drum winches stems from several key design and engineering principles. The dual drum configuration allows for balanced load distribution, minimizing stress on the winch mechanism and extending its operational life. This also enables the synchronized or independent control of two distinct lines, offering unparalleled precision for intricate lifting and pulling tasks. Our winches incorporate robust gear reduction systems, often helical or planetary gears, which provide high torque output and smooth, quiet operation. The use of Variable Frequency Drives (VFDs) for motor control ensures precise speed regulation, enabling soft starts and stops, which significantly reduces wear on the wire rope and mechanical components.

Safety is integrated into every aspect, with features such as automatic braking systems, overload protection, and emergency stop functionalities. These sophisticated controls, combined with heavy-duty construction, contribute to superior performance metrics including higher lifting speeds under full load, reduced power consumption, and minimal maintenance requirements. For specialized applications requiring portability and lower power consumption, options like the small electric winch 120v provide a compact yet powerful solution without compromising on essential features or reliability.

Customization Solutions and Manufacturer Insights

Choosing the right manufacturer for double drum winches is as crucial as selecting the equipment itself. A reputable manufacturer offers not just a product but a partnership, providing tailored solutions, comprehensive technical support, and reliable after-sales service. Our commitment to client-specific needs is reflected in our extensive customization capabilities. We understand that standard winches may not always meet the unique challenges of every project. Therefore, we offer bespoke engineering solutions, adjusting parameters such as pulling force, rope capacity, speed, motor type (including specialized electric winch 120v configurations), and control systems to precisely match operational requirements.

Our design process involves close collaboration with clients, employing advanced CAD and simulation tools to develop winches that integrate seamlessly into existing infrastructures and adhere to industry-specific regulations. This consultative approach ensures that each double drum winch is optimized for performance, safety, and longevity, delivering maximum return on investment. Our extensive service history and deep industry knowledge enable us to navigate complex technical challenges and deliver solutions that consistently exceed expectations.

Real-World Applications and Client Success Stories

Our track record of delivering high-performance double drum winches is supported by numerous successful applications and positive client feedback. For instance, a major infrastructure project recently deployed our heavy-duty double drum winches for the precise lifting and positioning of bridge segments over a challenging river crossing. The synchronized control of both drums was critical in maintaining stability and alignment, resulting in a project completion ahead of schedule and within budget, with minimal operational risks.

In another instance, a client in the offshore oil and gas industry utilized our specialized double drum winches for the controlled deployment and retrieval of subsea exploration equipment. The winches, customized with advanced remote monitoring and emergency braking systems, performed flawlessly in demanding deep-water conditions, ensuring the safety of personnel and the integrity of high-value assets. These case studies underscore our capability to provide reliable, efficient, and tailored winch solutions that stand up to the most rigorous industrial demands. Our long-term partnerships with clients are testament to our consistent service excellence and product durability.

Ensuring Trust and Authority: Our Commitment

Our dedication to quality and customer satisfaction is built on a foundation of trust and authoritative practices. All our double drum winches, including the Electric Winch Drum Winch 12V Transfer Gear Double Drum Winches, undergo rigorous testing and quality assurance protocols, compliant with international standards such as ISO 9001:2015. Each unit is subjected to load testing and operational performance checks before dispatch, ensuring peak reliability upon installation.

Frequently Asked Questions (FAQ)

- ✓ What is the typical lead time for custom double drum winches?

Our standard delivery cycle for custom orders ranges from 8 to 12 weeks, depending on complexity and material availability. Expedited options are available upon request. - ✓ What warranty is offered on your products?

We provide a comprehensive 12-month warranty on all mechanical and electrical components, covering manufacturing defects and ensuring peace of mind. - ✓ Do you provide installation and maintenance support?

Yes, we offer on-site installation supervision, commissioning services, and comprehensive maintenance support agreements to maximize your equipment's uptime.

Our commitment extends beyond product delivery, offering robust customer support, including technical assistance and spare parts availability, ensuring long-term operational excellence for all our double drum winches.

Conclusion: The Future of Industrial Winching

The evolution of double drum winches reflects the ongoing demand for more powerful, precise, and reliable lifting and pulling solutions in industrial environments. From the compact and efficient small electric winch 120v to heavy-duty, customized systems, these machines are pivotal in enhancing operational safety, productivity, and cost-effectiveness across diverse sectors. Our unwavering commitment to engineering excellence, adherence to international quality standards, and customer-centric approach positions us at the forefront of this technological advancement. We continue to innovate, providing industrial partners with the robust and intelligent winch solutions necessary to meet the complex challenges of tomorrow's infrastructure and resource development.

References

- "Machinery's Handbook," 31st Edition, Industrial Press Inc.

- "Mechanical Design of Machine Elements and Machines," Jack E. Fernandez and Colin B. Brown, Oxford University Press.

- "Standard Handbook for Mechanical Engineers," 12th Edition, McGraw-Hill Education.

- "ISO 9001:2015 Quality Management Systems – Requirements," International Organization for Standardization.

Previous

This is the first article-

Customized Marine Winches for Business RequirementsNewsJul.31,2025

-

Customized Single Drum Hoist Winches with BearingsNewsJul.31,2025

-

Innovative Grooved Split Drum Electric Mooring Winch SolutionsNewsJul.31,2025

-

Oxygen-Free Carburized Bevel Gears for MachineryNewsJul.31,2025

-

Multi-layer Winding Metal Cable Drums for RopesNewsJul.31,2025

-

S355J2+N Marine Winch Rope Drums for Large SizesNewsJul.31,2025