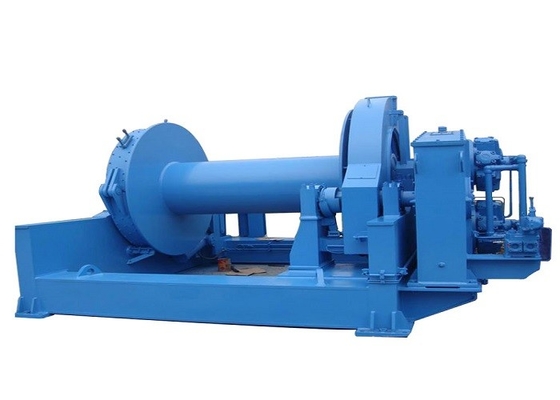

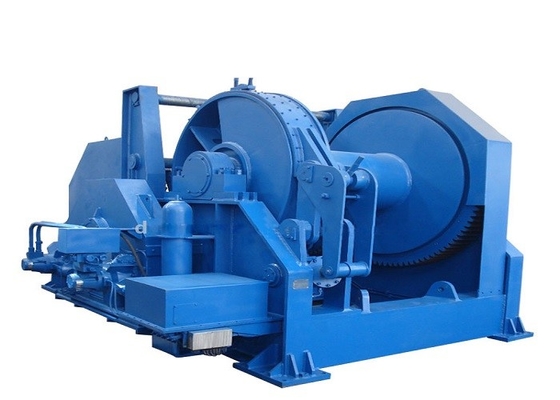

Powerful Double Drum Hydraulic Winch - Reliable & Efficient

Advancing Operations with Advanced Double Drum Hydraulic Winches: Industry Trends and Innovations

In the demanding landscape of marine, offshore, and industrial operations, the double drum hydraulic winch stands as a cornerstone of efficiency and reliability. This sophisticated piece of equipment is designed for intricate tasks requiring precise control over two independent or synchronized lines, offering unparalleled versatility in applications ranging from deep-sea fishing to complex construction and material handling. Current industry trends highlight a significant shift towards enhanced automation, integrated monitoring systems, and superior energy efficiency, driven by the escalating costs of operation and stringent environmental regulations. Manufacturers are focusing on compact designs with higher power-to-weight ratios, allowing for easier integration into diverse platforms without compromising pulling capacity or operational speed. The emphasis is increasingly on intelligent control systems that can automatically adjust tension, speed, and payout, minimizing human error and maximizing operational safety. Furthermore, the adoption of advanced materials for corrosion resistance and extended service life is paramount, especially in harsh marine environments. The market is also witnessing a surge in demand for customizable solutions, acknowledging that off-the-shelf products often fall short of the unique requirements of specialized industrial projects. This necessitates a close collaboration between winch manufacturers and end-users to engineer bespoke solutions that deliver optimal performance and long-term value.

The evolution of hydraulic systems, particularly closed-loop designs, contributes significantly to the superior performance and efficiency of modern double drum hydraulic winches. These systems offer finer speed control and greater torque density compared to their predecessors, translating into more responsive and powerful hoisting or pulling capabilities. The integration of proportional valves and advanced PLC (Programmable Logic Controller) systems enables operators to execute complex maneuvers with pinpoint accuracy, crucial for delicate marine operations such as net handling or precise anchor placement. Environmental considerations are also shaping product development, with a growing demand for hydraulic fluids that are biodegradable and systems designed to minimize oil leakage. This commitment to sustainability extends to noise reduction technologies, which are becoming a standard feature to comply with occupational health and safety regulations. As industries become more interconnected and global, the interoperability of winch systems with other vessel or platform control systems is also a critical factor, driving the development of standardized communication protocols. The robust design of a hydraulic drum winch ensures consistent performance under extreme conditions, making it an indispensable asset for operations where reliability cannot be compromised. The ability of the double drum hydraulic winch to manage multiple lines simultaneously or independently offers strategic advantages in time-sensitive operations, reducing operational windows and increasing overall productivity.

Key Technical Specifications and Performance Parameters

Understanding the technical specifications of a double drum hydraulic winch is crucial for effective deployment and optimal performance in demanding environments. Key parameters include rated line pull, line speed, drum capacity, motor power, and overall dimensions. For instance, the "Double Drum Hydraulic Net Winch 1500 Watt Marine Drum Winch" is specifically engineered for marine applications, highlighting its hydraulic efficiency and robust construction. The rated line pull, typically measured in tonnes or kilonewtons (kN), indicates the maximum force the winch can exert, a critical factor for lifting heavy nets or anchors. Line speed, expressed in meters per minute (m/min), determines how quickly the operation can be completed, impacting overall productivity. Drum capacity, measured in meters of rope, specifies the length and diameter of the wire rope or synthetic line that each winch drum can accommodate. These winches often feature advanced braking systems, including dynamic braking and fail-safe mechanical brakes, ensuring the load is securely held even in the event of power loss. The hydraulic power unit (HPU), which includes the motor, pump, and reservoir, is another vital component, defining the winch's operational power and efficiency. Manufacturers also specify hydraulic pressure requirements (e.g., 20 MPa to 25 MPa) and flow rates, which are essential for integrating the winch into existing hydraulic systems on vessels or industrial sites.

The power rating, such as 1500 Watt for the marine drum winch, directly correlates with the torque output and speed capabilities, reflecting its capacity for heavy-duty operations. Furthermore, the selection of materials plays a significant role in the longevity and reliability of these systems. High-strength steel alloys, often treated for enhanced corrosion resistance (e.g., marine-grade epoxy coatings or hot-dip galvanization), are standard for the frame and drum construction. Gearing mechanisms, frequently planetary or helical gearboxes, are designed for high efficiency and minimal maintenance, contributing to the winch's overall power transmission. Electrical components, including control panels and sensors, are typically IP-rated for ingress protection against dust and water, a necessity for harsh operational environments. Understanding these detailed parameters allows engineers and procurement specialists to select a winch drum system that aligns precisely with the operational demands, environmental conditions, and safety standards of their specific projects. The interplay of these technical specifications determines the winch's suitability for high-load cycles, continuous operation, and adaptability to varying operational speeds and loads, ensuring robust and consistent performance over its long service life.

Typical Double Drum Hydraulic Winch Parameters

| Parameter | Value Range | Unit/Description |

|---|---|---|

| Rated Line Pull (per drum) | 5 - 50+ | Tonnes / kN |

| Rated Line Speed | 5 - 30 | m/min |

| Drum Capacity (Wire Rope) | 100 - 1500 | Meters (depends on diameter) |

| Hydraulic Motor Power | 15 - 200 | kW |

| Hydraulic System Pressure | 16 - 28 | MPa |

| Control System | Local / Remote / PLC | Types of Control |

| Braking System | Hydraulic / Manual / Automatic | Redundant safety features |

| Weight (excluding HPU) | 500 - 15000 | kg |

The Advanced Craftsmanship of Double Drum Hydraulic Winch Manufacturing

The manufacturing process of a double drum hydraulic winch is a testament to precision engineering and robust material science, ensuring durability and high performance in the most arduous conditions. The journey begins with the selection of premium-grade materials, typically high-tensile carbon steel or stainless steel alloys, chosen for their superior strength-to-weight ratio and corrosion resistance, especially critical for marine and offshore applications. Components such as the winch drum itself, the main frame, and critical gears undergo rigorous manufacturing processes. Large sections of the frame and drum shells are often subjected to precision CNC (Computer Numerical Control) machining, which ensures exact dimensional accuracy and perfect alignment, minimizing friction and wear during operation. For load-bearing components, forging is frequently employed to enhance grain structure and eliminate internal defects, resulting in parts with exceptional fatigue strength. Smaller, complex parts might utilize investment casting or sand casting, followed by extensive post-processing to achieve the required surface finish and dimensional tolerances. The manufacturing sequence includes stages like material preparation, cutting, welding (using certified welders and advanced techniques like submerged arc welding for deep penetration), machining, heat treatment for stress relief and hardness, and surface preparation (e.g., sandblasting) before protective coatings are applied.

Quality control is integrated at every stage, from raw material inspection to final assembly and testing. Non-destructive testing (NDT) methods, including ultrasonic testing, magnetic particle inspection, and radiographic testing, are routinely performed on welds and critical components to detect any subsurface flaws. Hydrostatic testing of hydraulic circuits ensures integrity and leak-free operation, while load testing verifies the winch's capacity under realistic operational conditions. Manufacturers adhere strictly to international standards such as ISO 9001 for quality management, and specific industry standards like API (American Petroleum Institute) for oil and gas equipment, or DNV-GL, Lloyd's Register, and ABS for marine applications. These certifications not only ensure compliance but also attest to the winch's reliability and safety. The average service life of a well-maintained drum winch can exceed 20 years, a testament to the robust design and meticulous manufacturing. These winches find extensive application across diverse sectors, including petrochemical for pipeline installation, metallurgy for heavy lifting, and water supply/drainage for infrastructure projects. In these typical application scenarios, the double drum hydraulic winch offers significant advantages such as energy efficiency through optimized hydraulic power management, precise load control to prevent damage, and superior anti-corrosion properties to withstand aggressive chemical or saline environments, ensuring long-term operational integrity and reduced maintenance costs.

Diverse Application Scenarios and Distinct Technical Advantages

The versatility of the double drum hydraulic winch positions it as an indispensable asset across a multitude of high-demand industries. In the marine sector, its primary roles include deep-sea fishing, where precise control over large fishing nets is essential, and offshore operations like anchor handling, towing, and mooring. The ability to manage two lines independently allows for complex maneuvers such as simultaneously deploying and retrieving equipment or maintaining tension on two separate points, which is crucial for stability in dynamic environments. Beyond marine applications, these robust winches are critical in civil engineering for bridge construction, dam maintenance, and large-scale infrastructure projects requiring heavy lifting or precise tensioning. In the petrochemical industry, they are utilized for pipe-laying operations, tensioning cables, and handling heavy components in hazardous environments, often requiring ATEX certification for explosive atmospheres. The metallurgical industry benefits from their controlled power for positioning heavy furnaces, ladles, or rolling mill components. Furthermore, in specialized sectors like scientific research, these winches are employed for deploying oceanographic instruments to precise depths or retrieving geological samples. The inherent safety features, such as automatic braking and overload protection, are paramount in these high-stakes environments, preventing accidents and equipment damage.

The technical advantages of a hydraulic drum winch are multifaceted. Firstly, the superior power density of hydraulic systems allows for massive forces to be generated from relatively compact units, making them ideal for applications with limited space. Secondly, hydraulic winches offer infinitely variable speed control, enabling operators to achieve very slow, precise movements for delicate operations or rapid deployment when speed is critical. This level of control surpasses that of electric winches in many heavy-duty scenarios. Thirdly, the inherent overload protection of hydraulic systems prevents damage to the winch or the load; if the load exceeds the system's capacity, the hydraulic pressure simply stalls, rather than burning out a motor. Fourthly, hydraulic systems are less susceptible to environmental factors like dust, moisture, and extreme temperatures compared to electrical components, contributing to their reliability in harsh conditions. Lastly, the robust construction and fewer moving parts in the drive train lead to lower maintenance requirements and extended operational lifespans. The specific "Double Drum Hydraulic Net Winch 1500 Watt Marine Drum Winch" exemplifies these advantages, offering exceptional control and durability for challenging marine netting operations, contributing significantly to improved operational efficiency, safety, and reduced lifecycle costs across its diverse applications.

Manufacturer Comparison and Tailored Custom Solutions

When procuring a double drum hydraulic winch, selecting the right manufacturer is as crucial as defining the technical specifications. The market features several reputable manufacturers, each with distinct specializations and approaches to design, production, and after-sales support. Key differentiators often include the level of customization offered, adherence to international quality and safety standards, the range of available capacities, technological innovations (e.g., remote diagnostics, advanced control algorithms), and the global service network. Some manufacturers excel in standardized, high-volume production, offering competitive pricing, while others focus on highly engineered, custom-built solutions for niche or extremely demanding applications. For instance, LBS Winch, with its "Double Drum Hydraulic Net Winch 1500 Watt Marine Drum Winch," focuses on specialized marine applications, offering solutions that prioritize durability and specific functionalities required for net handling. Evaluating a manufacturer involves scrutinizing their engineering capabilities, their track record of successful projects, customer testimonials, and their responsiveness to unique client requirements. It is essential to consider not just the initial purchase price but the total cost of ownership, which includes maintenance, spare parts availability, and the expected operational lifespan. A thorough comparison will reveal differences in component sourcing, manufacturing tolerances, and the robustness of safety features, all of which impact long-term reliability and operational safety.

Customization is often a critical factor for B2B clients, as standard winch drum models may not perfectly fit highly specialized operational envelopes, environmental constraints, or integration challenges. Leading manufacturers offer comprehensive customization programs, allowing clients to specify unique requirements for line pull, speed, drum capacity, control systems (e.g., integration with vessel management systems, wireless remote control), material selection (e.g., for extreme corrosion or low-temperature environments), and certification to specific class societies (e.g., DNV, ABS, LR). This bespoke approach ensures that the winch is optimized for the intended purpose, leading to enhanced performance, greater operational efficiency, and a longer service life. Custom solutions may involve designing a compact footprint for tight spaces, developing specialized fairlead systems to guide the rope, or incorporating advanced data logging capabilities for performance monitoring and predictive maintenance. Working with a manufacturer adept at custom solutions means engaging in a collaborative design process, leveraging their engineering expertise to develop a winch system that not only meets but often exceeds the project's unique demands, delivering significant operational and economic benefits over the life of the asset.

Comparative Analysis: Leading Double Drum Hydraulic Winch Manufacturers

| Feature/Manufacturer | Manufacturer A (General Purpose) | Manufacturer B (Specialized Marine) | LBS Winch (Double Drum Hydraulic Net Winch 1500W) |

|---|---|---|---|

| Primary Focus | Broad industrial applications | Offshore & Heavy Marine | Specific Marine Net & Light Duty |

| Customization Level | Moderate (standard options) | High (engineer-to-order) | High (application-specific focus) |

| Typical Lead Time | 10-14 weeks | 16-24 weeks | 8-12 weeks (for standard customizations) |

| Certifications | ISO 9001 | ISO 9001, DNV-GL, ABS, API | ISO 9001, specific marine class approvals on request |

| Post-Sales Support | Regional service centers | Global network, remote diagnostics | Dedicated technical support, global parts network |

| Innovative Features | Basic automation | Advanced PLC, real-time monitoring | User-friendly controls, robust marine-grade design |

Real-World Application Cases and Client Experience

The practical effectiveness and reliability of a double drum hydraulic winch are best demonstrated through real-world application cases and the invaluable feedback from clients. Consider a prominent deep-sea fishing enterprise operating in the North Atlantic. They integrated a custom-built double drum hydraulic winch, similar to the "Double Drum Hydraulic Net Winch 1500 Watt Marine Drum Winch," onto their trawlers. The challenge was to efficiently manage vast fishing nets, which require precise and synchronized handling of both the main net and the secondary lines to optimize deployment and retrieval while minimizing damage to the catch and equipment. The winch's hydraulic system offered the precise speed and tension control necessary for these delicate yet demanding operations. The client reported a significant reduction in net damage, leading to lower repair costs and increased operational uptime. Furthermore, the winches’ robust construction and marine-grade protective coatings effectively resisted the corrosive saltwater environment, significantly extending the equipment's lifespan beyond initial expectations. This direct experience highlights the critical role of reliability and precision in economically viable maritime operations, providing a tangible example of how advanced winch technology directly translates into tangible business advantages.

Another compelling case involves a leading offshore energy company utilizing a high-capacity double drum hydraulic winch for anchor handling and subsea equipment deployment during the installation of floating offshore wind turbines. The project required extremely accurate positioning of anchors and the careful lowering of sensitive subsea components, often under challenging weather conditions. The hydraulic winch’s advanced control system, which included real-time load monitoring and automated tensioning, proved instrumental in ensuring the safety and precision of these complex maneuvers. The client specifically praised the system's ability to maintain constant line tension even with dynamic vessel movements, preventing slack lines or sudden load shifts that could jeopardize the entire operation. This level of reliability in critical offshore lifting scenarios underscores the inherent trust placed in a well-engineered drum winch. Post-project feedback consistently emphasized the winch's robust performance, minimal downtime for maintenance, and the responsive technical support provided by the manufacturer. These successful deployments not only validate the technical prowess of these systems but also build strong client relationships based on demonstrated performance and reliability in the most demanding operational contexts. These case studies underscore how tailored solutions and proven performance contribute to long-term operational success and client satisfaction.

Frequently Asked Questions (FAQ) about Double Drum Hydraulic Winches

-

Q1: What are the primary advantages of a double drum hydraulic winch over an electric winch for heavy-duty applications?

A1: Double drum hydraulic winches offer several distinct advantages for heavy-duty applications, particularly in marine and industrial environments. Firstly, they possess superior power density, meaning they can generate massive pulling forces from a more compact footprint, which is critical in space-constrained installations. Secondly, hydraulic systems inherently provide infinitely variable speed control, allowing for extremely precise and smooth load handling, crucial for delicate operations or managing dynamic loads. Electric winches, while capable, often require complex and costly variable frequency drives to achieve comparable control. Thirdly, hydraulic winches offer excellent overload protection; if the load exceeds the system's capacity, the hydraulic pressure simply stalls without damaging the motor, unlike electric motors that can burn out. Additionally, hydraulic systems are less susceptible to harsh environmental conditions such as moisture, dust, and extreme temperatures, making them more reliable and requiring less maintenance in challenging settings. This robust nature leads to a longer operational lifespan and reduced downtime, translating into significant cost savings over the equipment's lifetime.

-

Q2: How does the "Double Drum Hydraulic Net Winch 1500 Watt Marine Drum Winch" ensure high precision in net handling?

A2: The "Double Drum Hydraulic Net Winch 1500 Watt Marine Drum Winch" achieves high precision in net handling through a combination of advanced hydraulic controls and its dual-drum configuration. The hydraulic system incorporates proportional control valves and can be integrated with a Programmable Logic Controller (PLC). This allows operators to precisely control both the speed and tension of each drum independently or in synchronized mode. For net handling, this means the ability to adjust the payout and retrieval of different parts of the net at varying speeds to ensure optimal spread and retrieval, preventing tangles or damage. Real-time load sensing capabilities often provide feedback to the control system, enabling automatic adjustments to maintain constant tension, even if the vessel is moving or the net encounters resistance. The closed-loop hydraulic system ensures a highly responsive and accurate power delivery, minimizing lag and providing immediate reaction to operator inputs, which is paramount for delicate marine netting operations where precise movements are critical to operational efficiency and preventing costly damage to equipment or catch.

-

Q3: What are the typical delivery timelines and warranty provisions for custom double drum hydraulic winches?

A3: For custom double drum hydraulic winch solutions, delivery timelines can vary significantly based on the complexity of the design, the extent of customization required, and the current production schedule. Typically, a bespoke winch project, from design approval to factory acceptance testing, can range from 8 to 24 weeks. Standard models with minor customizations might have shorter lead times, often within 8-12 weeks. Major modifications or completely new designs involving extensive engineering can extend this period. At LBS Winch, we strive for efficient project management to meet agreed-upon deadlines while ensuring the highest quality. Regarding warranty, our products, including the "Double Drum Hydraulic Net Winch 1500 Watt Marine Drum Winch," typically come with a comprehensive 2-year warranty covering parts and labor against manufacturing defects. Extended warranty options are often available, subject to specific project requirements and negotiation. This commitment to quality and post-sales support underscores our dedication to long-term client satisfaction and ensures peace of mind regarding the reliability and performance of our advanced winch solutions.

Commitment to Trust, Quality, and Customer Support

Our unwavering commitment to delivering highly reliable and efficient double drum hydraulic winch systems is underpinned by a robust framework of quality assurance, transparent operational processes, and dedicated customer support. From the initial consultation to post-installation service, every phase is managed with meticulous attention to detail to foster enduring trust with our B2B partners. We adhere to stringent international manufacturing standards, including ISO 9001 quality management systems, ensuring that every winch drum we produce meets the highest benchmarks for design integrity, material quality, and operational performance. For our "Double Drum Hydraulic Net Winch 1500 Watt Marine Drum Winch," this includes rigorous testing protocols at various stages of production, such as non-destructive testing of welds, hydrostatic testing of hydraulic circuits, and comprehensive load testing to validate rated capacities and safety margins. Our certifications from leading classification societies, where applicable, further underscore our authority and adherence to global industry best practices.

Transparency in our delivery cycle is paramount. Once a custom solution or standard unit order for a drum winch is confirmed, clients receive clear communication regarding manufacturing progress, estimated delivery dates, and logistical arrangements. While typical lead times for bespoke solutions might range from 8 to 24 weeks depending on complexity, we provide realistic timelines and work diligently to meet them. Our commitment extends significantly beyond the point of sale through comprehensive warranty provisions and unparalleled customer support. Each double drum hydraulic winch typically comes with a standard 2-year warranty covering parts and labor, providing our clients with peace of mind. Our global network of certified technicians and readily available spare parts ensures that any operational issues are addressed swiftly and efficiently, minimizing downtime. We offer 24/7 technical assistance, remote diagnostics capabilities, and on-site support, reinforcing our dedication to maximizing the operational efficiency and longevity of your investment. This holistic approach to quality, delivery, and support builds a foundation of trust, making us a reliable partner for your most critical lifting and pulling requirements.

References & Authoritative Citations

- DNV GL. (2018). Rules for Classification of Ships, Pt.3 Ch.4, Lifting Appliances. Det Norske Veritas Germanischer Lloyd.

- ISO 9001:2015. (2015). Quality management systems – Requirements. International Organization for Standardization.

- Lloyd's Register. (2020). Rules and Regulations for the Classification of Ships, Part 3, Chapter 9: Lifting Appliances. Lloyd's Register Group Limited.

- Hydraulic Institute. (2017). Hydraulic Handbook. Hydraulic Institute Publications.

- API Specification 2C. (2019). Specification for Offshore Cranes. American Petroleum Institute.

Previous

This is the first article-

Customized Marine Winches for Business RequirementsNewsJul.31,2025

-

Customized Single Drum Hoist Winches with BearingsNewsJul.31,2025

-

Innovative Grooved Split Drum Electric Mooring Winch SolutionsNewsJul.31,2025

-

Oxygen-Free Carburized Bevel Gears for MachineryNewsJul.31,2025

-

Multi-layer Winding Metal Cable Drums for RopesNewsJul.31,2025

-

S355J2+N Marine Winch Rope Drums for Large SizesNewsJul.31,2025