Need a Grooved Drum Winch with Precise Spooling & High Load?

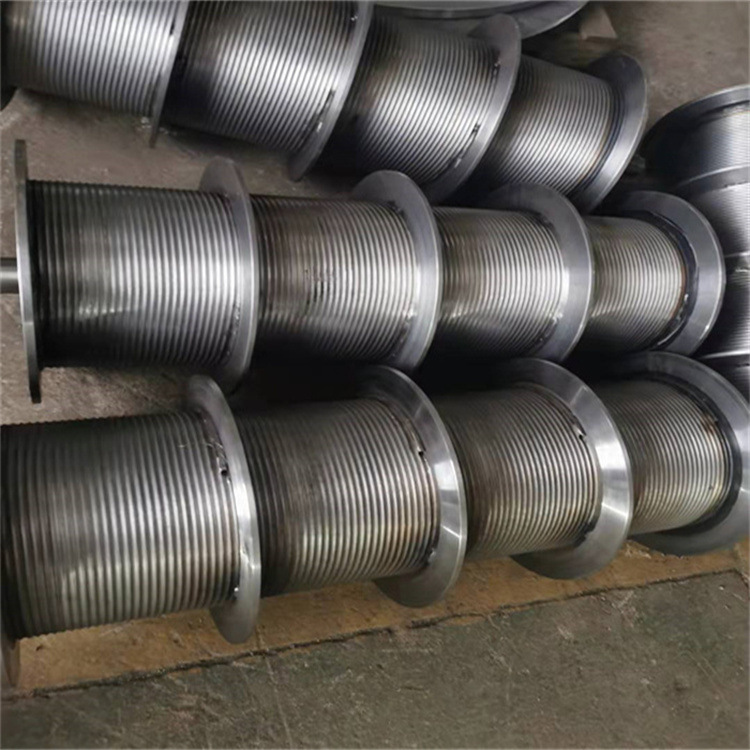

Quadruple Carbon Steel Grooved Winch Drum With Shaft: field notes from a lifting nerd

If you’ve ever wrestled with wire rope layering, you already know why a grooved drum winch matters. The short version: precise grooves control the rope path, cut crush damage, and keep lifts predictable. The long version—well, that’s why we’re here.

What’s new in grooved drums (and why you should care)

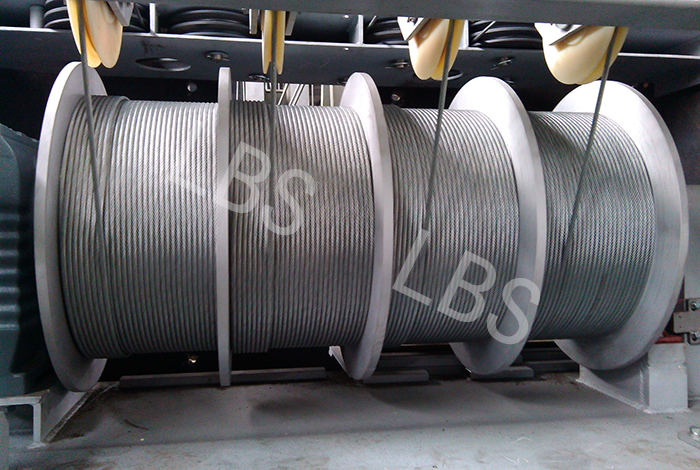

In port, offshore, and tower crane circles, three trends keep popping up: extending rope life, preparing for compacted strands and high-strength synthetic lines, and reducing unplanned downtime. The Quadruple Carbon Steel Grooved Winch Drum With Shaft tackles all three with spiral and Lebus-style groove options. Operators say the rope finally “behaves,” which, frankly, is half the battle on windy quaysides.

Quick spec snapshot (≈ real-world figures)

| Product | Quadruple Carbon Steel Grooved Winch Drum With Shaft |

| Groove style | Lebus (multi-layer) or spiral; flange / non-flange; with or without shaft |

| Material | Carbon steel (≈ S355 / ASTM A572 Gr.50 range), HB 180–220 typical |

| Groove tolerance | ±0.2–0.3 mm; runout ≤0.3 mm (shop-tested) |

| Rope compatibility | Ø10–78 mm wire rope; synthetic by request (liner required) |

| Coating | Zinc-rich epoxy + PU topcoat ≈ 200–300 μm; salt-spray 480 h |

| Standards | ISO 4301/4309, ASME B30.7, DNV-ST-0378, FEM 1.001 guidance |

| FOB & MOQ | FOB US $0.5–9,999 per piece; MOQ 100; Supply ≈ 10,000 pcs/month |

| Origin | NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China |

Where it works

Offshore platform crane winches, port cranes, tower and crawler cranes, and gantry cranes. In short: anywhere layering control is non‑negotiable. Many customers say they see fewer bird nests and smoother re-reeving. Not magic—just consistent geometry.

Process flow, testing, and life expectancy

Materials are cut and rolled, then groove-machined on CNC lathes (multi-start Lebus patterns). Welds are UT/MT inspected; drums are dynamically balanced; grooves are gauged with certified pins. Typical proof-rotation and dimensional checks follow ISO 4309 rope guidance. Coatings get DFT readings and 480 h salt-spray checks. Service life? Around 8–15 years under planned maintenance—real-world use may vary with rope care and duty class.

Why a grooved drum winch saves money

- Rope life extension (often 15–35% in my notes) due to controlled pressure and no cross-binding.

- Safer spooling at low fleet angles—operators report calmer, more predictable lifts.

- Faster rope change-outs (the groove acts like a tutor for new technicians, to be honest).

Vendor snapshot (what buyers actually compare)

| Vendor | Groove accuracy | Coating | Lead time | Notes |

|---|---|---|---|---|

| LBS (this product) | ≈ ±0.2–0.3 mm | Zn-rich epoxy + PU | 4–8 weeks typical | Strong Lebus know-how; high volume capacity |

| Generic offshore supplier | ≈ ±0.3–0.5 mm | Epoxy (std.) | 6–10 weeks | Broad catalog; variable MOQs |

| Local fabricator | Depends on CNC | Powder/paint | 2–6 weeks | Fast but needs detailed drawings |

Case notes (real sites, quick wins)

- Port crane retrofit: rope wear down ≈27% after six months; fewer mid-shift cutbacks.

- Offshore pedestal crane: grooved drum winch with hybrid Lebus pattern stabilized layering in squalls; operators called it “boringly consistent,” which is a compliment.

Customization & ordering

Options: flange or non-flange, shafted or hub-only, groove pitch tailored to rope diameter/lay, synthetic liners, DNV/ABS class witness if needed. Pricing sits in a broad band (see FOB), and yes, MOQ is 100. For multi-yard programs, capacity (≈10k pcs/month) keeps schedules intact. If your spec sheet is a little messy, send it anyway—I’ve seen worse, and a grooved drum winch design can be tuned fast once rope data and fleet angles are confirmed.

Certifications, compliance, and test data

Works within ISO 4301 duty classes; rope handling aligned to ISO 4309; offshore use guided by DNV-ST-0378 and API 2C practices. ASME B30.7 covers the hoist side. Typical shop docs: MTCs, NDT reports (UT/MT), balance reports, DFT logs, and dimensional charts. Honestly, paperwork is half the product—and worth it.

References

- ISO 4309: Cranes—Wire ropes—Care and maintenance, inspection and discard

- ASME B30.7: Base-Mounted Drum Hoists

- DNV-ST-0378: Standard for Offshore and Platform Lifting Appliances

- API Spec 2C: Offshore Pedestal-Mounted Cranes

- FEM 1.001: Rules for the Design of Hoisting Appliances

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025