Double Line Electric Hoist: Faster, Safer, Stronger?

double line electric hoist,25000 lb electric winch,5 ton electric winch is a key solution in the machinery manufacturing industry industry, specifically within Manufacturing of lifting and transportation equipment and Manufacturing of marine lifting equipment. This article explores how Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- double line electric hoist,25000 lb electric winch,5 ton electric winch Overview

- Benefits & Use Cases of double line electric hoist,25000 lb electric winch,5 ton electric winch in Manufacturing of marine lifting equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in machinery manufacturing industry

- Conclusion on double line electric hoist,25000 lb electric winch,5 ton electric winch from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

double line electric hoist,25000 lb electric winch,5 ton electric winch Overview

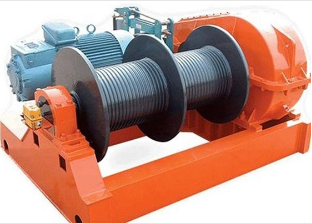

In marine environments, reliable lifting and pulling equipment underpins safe, efficient deck operations. A double line electric hoist uses two-part reeving to effectively double line pull at the hook, while electric winches translate motor torque into controlled linear force for mooring, anchoring, and launch-and-recovery tasks. Across capacities—from a compact 5 ton electric winch to a robust 25000 lb electric winch—B2B buyers seek consistent line speed, precise control, and low lifecycle cost. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. engineers electric marine winches with large rope capacity, double-grooved drums for accurate spooling, and marine-duty coatings to withstand salt spray and continuous deck vibration.

Technically, the company’s electric winch solutions can be configured with high-efficiency motors, helical or planetary gearboxes, fail-safe electromagnetic brakes, and variable frequency drives (VFDs) for soft start, creep speeds, and overload protection. Double-grooved drums help maintain layer-to-layer line lay, reducing rope wear and minimizing crush damage—critical when handling wire rope on long drum barrels. Integrated control options range from local push-button stations to PLC-based systems with remote operation. Whether you are specifying a 5 ton unit for davit handling or evaluating higher pulls aligned with the 50-ton class showcased on the product page, Junzhong’s designs emphasize safety margins, predictable torque, and dependable duty cycles.

Benefits & Use Cases of double line electric hoist,25000 lb electric winch,5 ton electric winch in Manufacturing of marine lifting equipment

Marine builders and operators rely on configurable solutions that cover mooring winches, anchor handling, towing, slipway/ship-lift applications, and A-frame or davit systems. A 5 ton electric winch is often selected for utility tasks, boat handling, or ROV umbilical management, while a 25000 lb electric winch aligns with heavier deck machinery, towing auxiliaries, and shore-based slipways. For on-deck hoisting, the double line electric hoist setup delivers higher hook loads at controlled speeds, giving crews precise handling of equipment, stores, and mission packages in sea states where smooth control is paramount.

Key advantages include steady torque at low speeds, accurate inching with VFD control, and enhanced spooling through double-grooved drum geometry. Electric actuation also simplifies integration with vessel power and digital control systems, supporting interlocks, load monitoring, and alarms. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. is experienced in engineering marine-duty winches with large rope capacity to extend operational envelopes and reduce changeovers. Optional features—such as marine-grade enclosures, heaters, protective coatings, and custom foundations—help tailor solutions to class requirements and environmental conditions, enabling OEMs and shipyards to streamline installation while maintaining compliance and safety.

Cost, Maintenance & User Experience

Total cost of ownership in marine lifting equipment is driven by energy use, rope life, planned maintenance, and downtime. Electric winches from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. are designed for serviceability: accessible brake assemblies, standardized bearings and seals, and rugged geartrains that maintain alignment over time. Double-grooved drums improve line lay, which can help extend rope life—reducing frequent replacements and saving on consumables. Compared with hydraulic systems, electric drives can lower operating costs through higher efficiency, reduced leak risks, and simplified power distribution.

B2B decision makers report that consistent line speed, quiet operation, and intuitive controls improve crew confidence and reduce training time. From a smaller 5 ton electric winch to a 25000 lb electric winch, the ability to fine-tune acceleration and deceleration via VFDs enhances load protection and deck safety. Budget planning typically centers on line pull, line speed, drum capacity, materials, and control architecture. Junzhong supports lifecycle value through application engineering, factory testing, on-site commissioning assistance, and long-term parts availability—factors that contribute to predictable ROI and smoother resupply planning across fleets and shipyards.

Sustainability & Market Trends in machinery manufacturing industry

The machinery manufacturing industry—especially in marine applications—is shifting toward electrification, digitalization, and cleaner operations. Electric winches eliminate hydraulic fluid spill risk and can deliver measurable energy efficiency gains, especially when paired with VFDs that optimize power draw and enable regenerative braking on appropriate systems. As ports and shipyards pursue decarbonization, electric deck machinery supports emissions goals and reduces environmental exposure.

Regulatory expectations around safety, noise, and environmental protection continue to rise. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. adopts a forward-thinking approach by offering marine-duty protection systems, corrosion-resistant finishes, and control options that facilitate monitoring, diagnostics, and integration with vessel automation. Predictive maintenance, enabled by sensor data and condition monitoring, is becoming a standard expectation for fleet operators who want to avoid unscheduled downtime. In this landscape, right-sizing a double line electric hoist or specifying a 5 ton to 25000 lb electric winch with accurate spooling and strong braking provides dependable performance today while aligning with future-ready, eco-conscious operations.

Conclusion on double line electric hoist,25000 lb electric winch,5 ton electric winch from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

From utility handling to heavy-duty marine operations, a well-specified double line electric hoist and electric winches in the 5 ton to 25000 lb range deliver precise control, reliability, and long-term value. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. combines engineering rigor with marine-oriented design—double-grooved drums, robust braking, and smart controls—so B2B teams can standardize on durable, efficient equipment. Explore how these solutions can improve safety, uptime, and lifecycle costs across your fleet or facility.

Contact us: email: lbswinch@lebus.com.cn

Visit our website: https://www.lbswinch.com

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025