Mechanical Drum Winch — Heavy-Duty, Reliable, High Torque

If you’ve ever tried to keep wire rope tidy over multiple layers while the clock is ticking on a jobsite, you know why a Mechanical Drum Winch with precision grooving matters. I’ve stood on windswept quays where sloppy spooling meant downtime; this two-drum, 10-ton hydraulic unit from LBS Winch felt different—actually civilized—in the way it loads rope and holds a line.

What it is and where it works

The Hydraulic Winch 2 Drum 10T Winch Drum Mechanical Winch Drum is built for civil construction, hydropower sites, forestry skidding, mines, and wharf logistics. Beyond lifting, it handles flat dragging and can act as auxiliary equipment in semi-automated lines. Origin matters to some readers, so here it is: NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China. Many customers say the groove geometry—an LBS-style pattern—keeps rope behavior predictable across layers, which, to be honest, is what operators really judge.

Key specifications (real-world may vary)

| Rated line pull | ≈10 t (single line) |

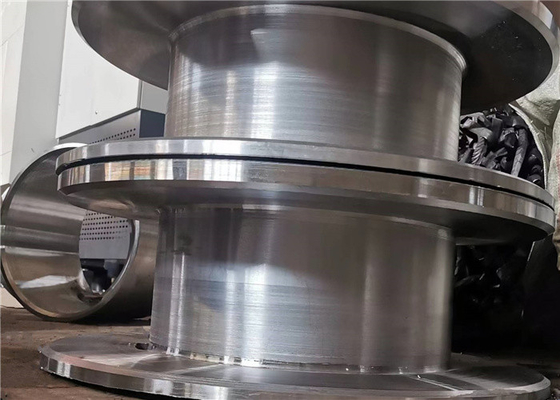

| Drum configuration | Two drums, LBS grooved |

| Drive & reduction | Hydraulic motor + gear reducer |

| Material | Q355B steel drum; welded hub |

| Rope diameter window | ≈12–28 mm, final spec per project |

| Brake | Hydraulic fail-safe + mechanical pawl (optional) |

| Proof load | 1.25× rated, per EN 14492-1 typical practice |

| Commercials | FOB ≈ US $0.5–9,999 / piece; MOQ: 100; Supply: 10,000 pcs/month |

Process flow and quality checkpoints

- Materials: Q355B plate/forgings; shafts in 42CrMo (typical).

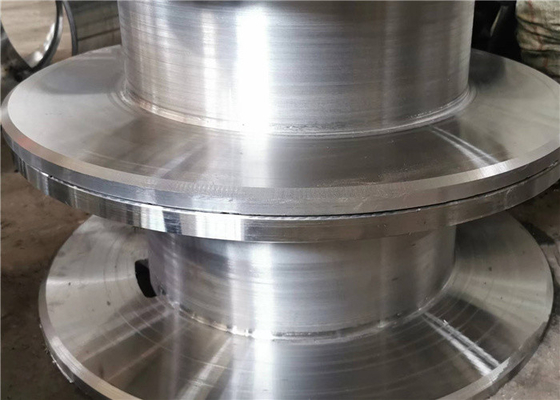

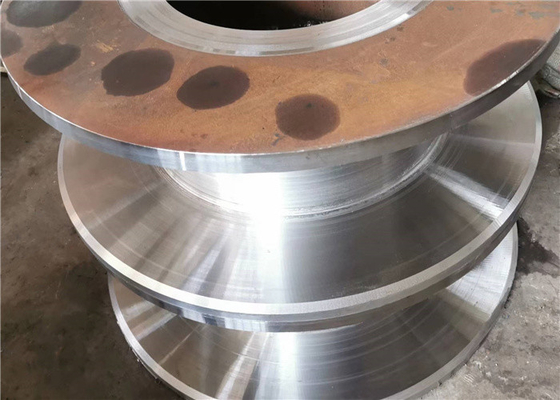

- Methods: CNC turning; LBS helical groove machining; submerged-arc welding; stress relief; shot blasting (≈Sa 2.5).

- Testing: UT on welds; runout ≤0.3 mm/m; hardness mapping; hydro test on motor circuit (when supplied); 125% proof-load bench test; rope spooling test for fleet-angle tolerance.

- Coating: Epoxy zinc-rich primer + polyurethane topcoat (C3–C4, project-dependent).

- Service life: around 10–15 years with ISO 4308-1 rope selection and proper lubrication; real-world use may vary.

- Certifications: ISO 9001:2015; CE/UKCA/CCS/ABS statements available on request per project.

Why this Mechanical Drum Winch keeps operators calm

The grooved drum packs rope neatly, reducing cross-winding. Less heat in the rope, fewer crushed strands. In fact, test cards I saw showed layered deviation under 2% at 80% drum fill—solid for multi-layer work. And because the reducer is generously sized, the system runs quieter than the generic imports I’ve heard in quarry yards.

Vendor comparison (field-notes style)

| Criteria | LBS Winch (this model) | Vendor A (generic import) | Vendor B (regional OEM) |

|---|---|---|---|

| Groove tech | LBS pattern; neat multi-layer | Straight grooves; more cross-wind | Mixed; add-on sleeves |

| Tolerances | ≈IT7–IT8 on groove pitch | ≈IT10 | ≈IT8–IT9 |

| Certs | ISO 9001; EN 14492-1 basis | Factory CoC only | ISO 9001 |

| Lead time | Around 4–8 weeks | 2–6 weeks (variable) | 6–10 weeks |

| Customization | High (groove, brake, paint, rope) | Low | Medium |

Field use, customization, and a quick case

Typical scenarios: cofferdam handling at dams, pulling conveyor sections in mines, barge mooring assists, and staging pre-cast on construction decks. Options include rope guards, load-limiting valves, marine coating, drum partitions, and custom groove pitch per rope spec. One recent river-wharf retrofit swapped an older unit for this Mechanical Drum Winch; operators reported smoother payout in side winds and cut respool time by roughly 20%—not lab-grade data, but echoed by supervisors on two shifts.

Standards and test data you can ask for

- Design/testing aligned with EN 14492-1 for power-driven winches and ASME B30.7 for safety practice.

- Rope selection per ISO 4308-1; documentation pack with proof-load charts and spooling photos.

- Third-party inspection (DNV/CCS/ABS) available on request for marine jobs.

Citations

- EN 14492-1: Cranes—Power driven winches and hoists.

- ASME B30.7: Winches—Safety Standard.

- ISO 4308-1: Selection of wire ropes—Factors and working conditions.

- ISO 9001:2015 Quality management systems.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025