Double Drum Winch for High Mast – Heavy-Duty, Precise, Safe

Double Drum Winch For High Mast is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of lifting and transportation equipment. This article explores how Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Double Drum Winch For High Mast Overview

- Benefits & Use Cases of Double Drum Winch For High Mast in Manufacturing of lifting and transportation equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Double Drum Winch For High Mast from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

Double Drum Winch For High Mast Overview

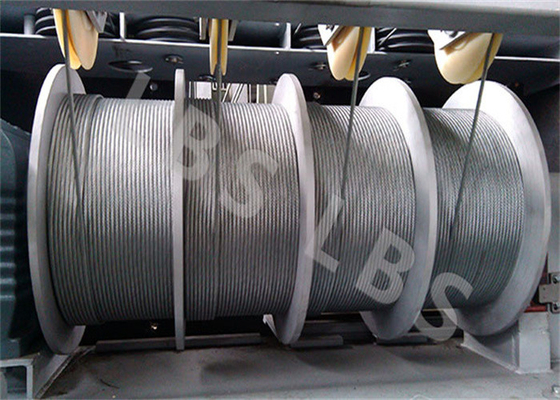

A Double Drum Winch For High Mast is engineered to raise and lower tall structures—such as high-mast lighting poles, communication towers, and maintenance platforms—safely and efficiently. Two coordinated drums manage separate wire ropes for synchronized lifting, precise tensioning, and built-in redundancy. For B2B decision makers in the Manufacturing of lifting and transportation equipment, this design improves uptime, operator safety, and serviceability compared to single-drum or manual systems. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. designs and manufactures robust electric drum winch systems with grooved steel drums that promote uniform spooling and extend rope life.

- Typical specifications can be tailored: 5–50 t rated line pull per drum, 5–20 m/min line speed, rope capacity 50–800 m, and 380–690 V, 50/60 Hz power. Options include VFD control, PLC synchronization, load monitoring, fail-safe disc brakes, limit switches, and IP55–IP66 electrical protection.

- Junzhong’s LBS-style grooved drums reduce wire-rope wear and improve layer formation—critical for high mast duty cycles. The same engineering principles are applied to double drum mooring winch configurations for marine and port applications.

- Backed by in-house machining, quality control, and application engineering, Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. is a reliable partner for customized high mast winches that integrate seamlessly into OEM equipment or retrofit projects.

Benefits & Use Cases of Double Drum Winch For High Mast in Manufacturing of lifting and transportation equipment

In factories and infrastructure settings, double-drum systems support safe, frequent raising/lowering cycles for tall luminaires, inspection platforms, and tower sections. OEMs of lighting masts, maintenance hoists, and service trolleys specify a Double Drum Winch For High Mast to maintain equal rope tension, minimize sway, and ensure level lifting. In ports, airports, and stadium complexes, the same platform scales into a double drum mooring winch or electric drum winch for utility handling, aligning standards across fleets and simplifying spares.

- Key features: synchronized dual-drum control, LBS grooved drums for perfect spooling, overload and slack-rope protection, precise speed control via VFD, and ergonomic pendant/HMI operation. These capabilities reduce maintenance windows and improve operator confidence.

- Competitive advantages: engineered-for-duty cycles, customizable footprints, integration with PLC/SCADA, and proven rope management that extends service intervals. The result is higher availability and lower lifetime costs compared with ad-hoc lifting solutions.

- Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. applies cross-industry expertise—construction, marine, and industrial lifting—to optimize each high mast configuration, from compact electric drives to heavy-duty drum assemblies for outdoor environments.

Cost, Maintenance & User Experience

Total cost of ownership for a Double Drum Winch For High Mast is driven by energy use, rope life, planned maintenance, and downtime. Junzhong’s electric drum winch solutions leverage high-efficiency motors and VFDs to curb energy consumption, while grooved drums and correct fleet angles reduce rope abrasion—often extending rope-change intervals and lowering consumable spend. Modular brake systems and accessible bearings simplify servicing, reducing labor hours and inventory complexity.

- Durability and ROI: Heavy-duty frames, sealed gearboxes, and corrosion-resistant finishes deliver long service life in outdoor installations. Many users report improved uptime and fewer emergency callouts after standardizing on a synchronized double-drum design.

- User experience: Smooth starts/stops, intuitive controls, and integrated safety interlocks reduce operator fatigue and training time. In the Special Equipment Manufacturing Industry, feedback highlights predictable lifting, cleaner spooling, and easier inspections as key contributors to ROI within typical 12–24 month horizons, depending on duty cycles.

Sustainability & Market Trends in manufacturing

Manufacturers are transitioning from hydraulic or diesel systems to electric drum winch platforms to meet decarbonization goals, reduce noise, and simplify compliance. Energy-efficient drives, regenerative braking (where applicable), and precision controls cut power consumption and extend component life. Regulations continue to promote safer lifting practices, more accurate load control, and responsible material use—trends that favor engineered, synchronized double-drum winches for high mast operations.

- Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. takes a forward-thinking approach: specifying high-efficiency motors, optimizing drum grooves to extend rope lifespan (reducing waste), and offering robust coatings for long outdoor service. Digital options—sensors for load/tension, remote status, and maintenance prompts—support predictive upkeep and safer operations.

- With infrastructure expansion in ports, airports, and smart cities, demand is rising for standardized winch platforms that can be configured as a Double Drum Winch For High Mast or a double drum mooring winch, ensuring scalability and lifecycle consistency across applications.

Conclusion on Double Drum Winch For High Mast from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

For B2B decision makers seeking reliable, safe, and service-friendly lifting solutions, a Double Drum Winch For High Mast delivers synchronized control, extended rope life, and lower total cost of ownership. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. combines proven grooved-drum engineering with configurable electric drum winch platforms to meet demanding duty cycles in the Manufacturing of lifting and transportation equipment. Partner with a team that understands your application and adapts the design to your site, standards, and budget.

- Contact us: email: lbswinch@lebus.com.cn

- Visit our website: https://www.lbswinch.com

- Explore product details: Product Page

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025