Large Drum Winch: High Capacity, 240V Electric—Need One?

[large drum winch,electric winch 240v,small electric winch 240v] is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of lifting machinery. This article explores how Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- [large drum winch,electric winch 240v,small electric winch 240v] Overview

- Benefits & Use Cases of [large drum winch,electric winch 240v,small electric winch 240v] in Manufacturing of lifting machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on [large drum winch,electric winch 240v,small electric winch 240v] from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

[large drum winch,electric winch 240v,small electric winch 240v] Overview

A large drum winch is an engineered hoisting and pulling system built around a single, robust drum and gearbox designed to handle substantial line pull and long rope capacities. In the Manufacturing of lifting machinery, these winches enable safe, controlled movement of heavy components, fixtures, and assemblies. For lighter-duty or distributed workstations, an electric winch 240v or a small electric winch 240v provides dependable performance on commonly available power supplies, supporting tasks such as positioning jigs, feeding lines, and light material handling.

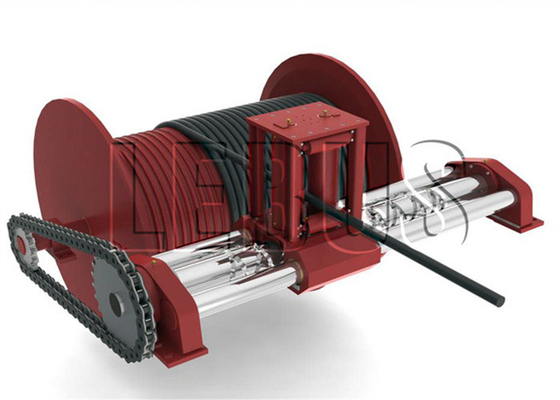

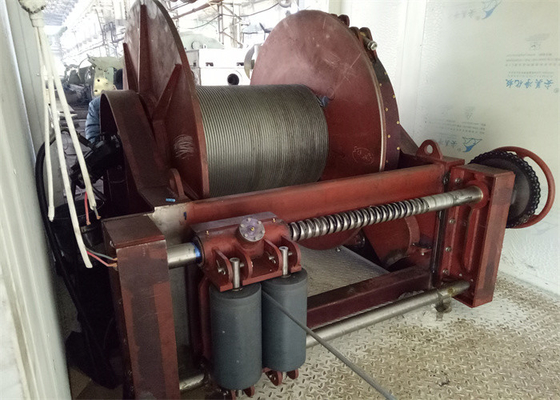

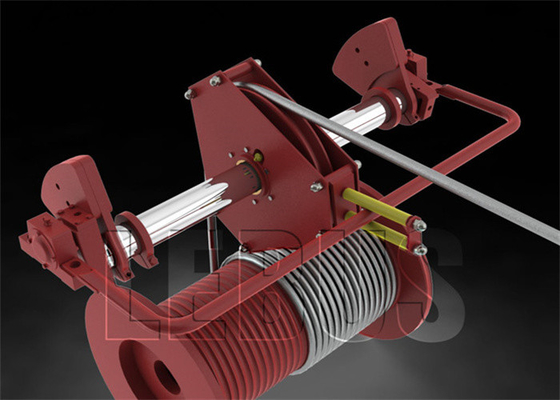

Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. manufactures single-drum electric winches with precision Lebus-style grooved drums and programmable spooling devices to ensure even rope lay, minimize wear, and improve safety. Typical configurations feature high-efficiency motors, sealed gearboxes, integrated brakes, overload protection, and options for variable frequency drives (VFD) to achieve soft start/stop and precise speed control. From compact 240V units to industrial large drum winches with multi-ton capacities, the company delivers solutions tailored to duty class, rope length, ambient conditions, and control logic—meeting the requirements of modern production lines and lifting systems.

Benefits & Use Cases of [large drum winch,electric winch 240v,small electric winch 240v] in Manufacturing of lifting machinery

Within lifting machinery manufacturing, winches are central to assembly bays, test stands, and integration lines. A large drum winch excels in handling long wire ropes and high loads for fabricating crane booms, steel structures, and modular equipment. It ensures consistent line pull during lifting, tilting, or load positioning operations. Where space and power access are limited, an electric winch 240v or small electric winch 240v can be deployed at individual workcells to assist with fixture changeovers, component indexing, and ergonomic material handling.

Key advantages include precise rope layering via grooved drums and powered spooling devices, which reduce bird-nesting and extend wire rope life. VFD-driven control enables accurate speed/torque profiles, lowering shock loads and improving product quality during assembly. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. differentiates with robust steel fabrication, tight machining tolerances, application engineering, and customization—such as special coatings, low-temperature packages, custom control panels, and remote or integrated PLC interfaces. This combination translates to safer operations, higher throughput, and fewer stoppages across crane assembly shops, equipment refurbishment centers, and OEM test facilities.

Cost, Maintenance & User Experience

Total cost of ownership is driven by energy use, rope/part consumption, uptime, and labor. Junzhong’s grooved drum and automatic spooling device maintain consistent rope tension and alignment, significantly reducing premature rope wear and replacement frequency. High-efficiency motors paired with VFDs cut energy waste and inrush currents, while sealed gearboxes and industrial brakes lower maintenance overhead. For smaller workstations, an electric winch 240v or small electric winch 240v leverages existing power infrastructure, avoiding costly rewiring and expediting deployment.

Maintenance is straightforward: routine rope inspection, lubrication schedules, gearbox oil checks, brake testing, and spooling device verification. The company provides clear documentation, spare parts support, and training to keep crews productive. B2B users in the Special Equipment Manufacturing Industry consistently report smoother rope lay, fewer line tangles, and improved cycle consistency—factors that translate into measurable ROI through higher throughput and reduced downtime. Whether upgrading an existing line or specifying new lifting machinery, these winches help standardize best practices and stabilize operational costs.

Sustainability & Market Trends in manufacturing

Manufacturers are prioritizing electrification, energy efficiency, and safer automation. Modern winch systems support these goals with high-efficiency motors, regenerative-ready drive options, and programmable controls that curb idle consumption and minimize mechanical stress. Robust grooving and spooling technologies extend rope life, thereby reducing material waste and maintenance interventions. Specifying recyclable steel components, durable finishes, and long-life seals further aligns lifting equipment with sustainability targets and evolving regulatory expectations.

Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. is advancing these trends with configurable controls, remote diagnostics readiness, and engineered drum/spooling designs that optimize performance per duty class. The company’s emphasis on longevity and rebuildability supports circular economy principles—keeping equipment in service longer and reducing lifecycle emissions. As the market moves toward smarter, safer, and more efficient lifting solutions, products ranging from compact electric winch 240v units to high-capacity large drum winches position B2B buyers to meet both production and ESG commitments.

Conclusion on [large drum winch,electric winch 240v,small electric winch 240v] from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

From heavy assembly and proof-load testing to precise workcell positioning, a large drum winch, electric winch 240v, or small electric winch 240v can elevate safety, throughput, and repeatability across lifting machinery manufacturing. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. delivers durable designs, controlled spooling, and application-specific engineering that help decision makers reduce TCO and operational risk. For specifications, pricing, and technical support: Contact us: email: lbswinch@lebus.com.cn. Visit our website: https://www.lbswinch.com

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025