High-Precision Grooved Drums for Optimal Wire Rope Winding

The Indispensable Role of Grooved Drum Technology in Modern Industries

In the intricate machinery of industrial operations, where precision, safety, and efficiency are paramount, the grooved drum stands as a cornerstone component. These specialized drums are crucial for managing wire ropes or cables in a multitude of hoisting, lifting, and pulling applications across diverse sectors. Unlike smooth drums, their precisely engineered grooves ensure consistent spooling, significantly extending cable life, enhancing operational safety, and optimizing power transmission. This article delves into the critical aspects of modern grooved drum technology, from manufacturing intricacies and technical parameters to wide-ranging applications and the strategic advantages they offer.

The evolution of grooved drum technology reflects the increasing demands for reliability and performance in demanding environments. Industries such as oil and gas, marine, mining, construction, and material handling rely heavily on winches and hoists equipped with superior grooved drum designs. Poor rope spooling can lead to premature rope failure, increased downtime, and significant safety hazards. Therefore, understanding the engineering excellence behind these components is not merely academic but a prerequisite for operational success and long-term cost efficiency.

Specifically, products like the Grooved Drum Skin Drum Winch Cover Grooved Sleeves For Smooth Drum represent a cutting-edge solution for upgrading existing smooth drum systems or enhancing the performance of new installations. These innovative sleeves offer the benefits of a full grooved drum without the need for complete drum replacement, providing a cost-effective path to superior rope management and increased operational longevity.

The Anatomy and Engineering of a Grooved Drum

A grooved drum, at its core, is a cylindrical component meticulously designed to guide and store wire rope, cable, or chain. Its defining feature is the helical or parallel grooving on its surface, which dictates the precise layering of the rope. This design is critical for preventing rope crossover, crushing, and subsequent damage, which are common issues with smooth drums under high load or repetitive cycles. The efficiency and safety of a winch or hoist system are profoundly influenced by the quality and design of its grooved drum.

Key Design Parameters and Components:

- Groove Profile: The most prevalent design is the Lebus grooving system, which involves precisely machined parallel and helical grooves that ensure a perfect level winding of the rope. Other profiles include helical grooves and sometimes random grooving for less critical applications. The Lebus system minimizes fleet angle issues and reduces wear on both the rope and the drum.

- Drum Diameter and Length: These dimensions are determined by the required rope capacity, lifting height, and available installation space. Larger diameters generally reduce rope bending fatigue.

- Rope Diameter Compatibility: Each grooved drum is designed for a specific range of wire rope diameters. The groove pitch and depth must precisely match the rope to ensure optimal winding and support.

- Material Selection: The choice of material is paramount, influenced by load requirements, environmental conditions, and desired service life.

- Carbon Steel: Commonly used for its strength and cost-effectiveness. Often heat-treated to enhance surface hardness and wear resistance.

- Alloy Steel: For higher strength, impact resistance, and fatigue life, especially in heavy-duty or dynamic applications. Examples include 42CrMo, 35CrMo, or customized alloys.

- Cast Iron: Offers good damping properties and machinability, suitable for certain moderate load applications.

- Stainless Steel: Chosen for corrosive environments (e.g., marine, chemical processing) due to superior corrosion resistance, albeit at a higher cost.

- Polymer/Nylon Sleeves: For applications requiring reduced weight or specialized non-metallic contact, often used as protective sleeves or inserts, like the Grooved Drum Skin Drum Winch Cover Grooved Sleeves For Smooth Drum.

- Surface Treatment: To enhance durability and corrosion resistance. Options include hardening, nitriding, induction hardening, chrome plating, or specialized coatings for specific environmental challenges.

Manufacturing Process Overview for a High-Quality Grooved Drum:

The manufacturing of a precision grooved drum is a multi-stage process requiring advanced engineering and stringent quality control. The goal is to achieve dimensional accuracy, surface integrity, and mechanical properties that withstand extreme operational stresses.

- Material Procurement and Inspection: Sourcing high-grade raw materials (e.g., steel billets, forged blanks) from certified suppliers. Incoming materials undergo chemical analysis and mechanical testing to ensure compliance with standards like ASTM, DIN, or JIS.

- Initial Forming (Casting or Forging):

- Forging: Preferred for drums requiring superior strength, toughness, and fatigue resistance. The process involves deforming metal under localized compressive forces using hammers or presses, refining grain structure, and eliminating porosity. This is common for high-load grooved drums in marine or mining sectors.

- Casting: Suitable for larger drums or those with complex geometries where forging might be impractical or uneconomical. While offering design flexibility, cast drums often require more rigorous post-casting treatments to achieve desired mechanical properties and reduce internal defects.

- Rough Machining: The formed blank is then rough machined on large lathes to achieve the basic cylindrical shape, preparing it for precision operations. This step removes excess material and ensures concentricity.

- Heat Treatment: A critical step to enhance the material's mechanical properties, such as hardness, strength, and wear resistance. This can include:

- Quenching and Tempering: For through-hardening.

- Normalizing: To refine grain structure.

- Induction Hardening: For surface hardening, providing wear resistance while maintaining a tough core. This is particularly effective for the groove surfaces of a grooved drum.

- Nitriding/Carburizing: Case hardening processes that introduce nitrogen or carbon to the surface, forming a hard, wear-resistant layer.

- Precision CNC Machining of Grooves: The most crucial step. High-precision CNC (Computer Numerical Control) lathes are used to cut the exact groove profile (e.g., Lebus or helical) onto the drum surface. The accuracy of this step directly impacts rope life and winding quality. Modern CNC machines achieve tolerances down to microns.

- Surface Finishing and Coating: Depending on the application, the drum surface may undergo grinding, polishing, or specialized coatings (e.g., hard chrome plating for extreme wear resistance, epoxy coatings for corrosion protection). For products like grooved sleeves, this stage ensures a smooth, durable exterior.

- Dynamic Balancing: For high-speed applications, drums are dynamically balanced to minimize vibrations and ensure smooth operation, which extends bearing life and reduces system wear.

- Final Quality Inspection and Testing: Comprehensive inspection covers:

- Dimensional Accuracy: Verification of all critical dimensions, including drum diameter, length, groove pitch, and depth, against engineering drawings.

- Non-Destructive Testing (NDT): Such as Ultrasonic Testing (UT) to detect internal flaws, Magnetic Particle Inspection (MPI) for surface cracks, or Dye Penetrant Inspection (DPI) for surface-breaking defects.

- Hardness Testing: To confirm the effectiveness of heat treatment.

- Surface Roughness Measurement: Ensuring optimal surface finish for rope contact.

- Load Testing (Simulated): In some cases, simulated load tests or functional tests are performed to validate performance.

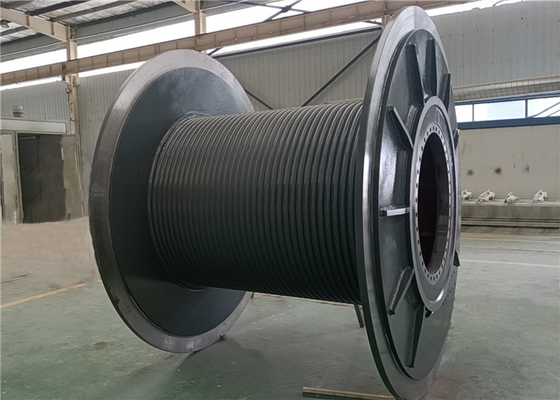

Image: A precisely machined grooved drum showcasing advanced manufacturing capabilities.

Industry Trends and Technological Advancements in Grooved Drum Design

The landscape of industrial machinery is continuously evolving, driven by demands for greater efficiency, safety, and sustainability. This evolution directly impacts the design and manufacture of components like grooved drums. Several key trends are shaping the future of this technology:

- Smart Drum Systems and IoT Integration: The integration of sensors and IoT (Internet of Things) technologies allows for real-time monitoring of drum performance, including load, temperature, vibration, and even rope wear. This data enables predictive maintenance, minimizes unexpected downtime, and optimizes operational parameters, leading to a significant increase in the operational lifespan of a grooved drum.

- Advanced Material Science: Research into new alloys and composite materials aims to create lighter, stronger, and more corrosion-resistant drums. For instance, high-strength steels with improved fatigue properties are extending service life in extreme environments. Developments in specialized coatings are also enhancing wear resistance and reducing friction, further prolonging the life of both the drum and the wire rope.

- Energy Efficiency: Optimized groove designs, reduced friction, and precision manufacturing contribute to lower energy consumption by minimizing power loss during winding and unwinding operations. This translates to significant cost savings and a reduced environmental footprint, aligning with global sustainability initiatives.

- Modularity and Customization: There is a growing trend towards modular grooved drum designs, including the use of split sleeves (like the Grooved Drum Skin Drum Winch Cover Grooved Sleeves For Smooth Drum). This allows for easier installation, maintenance, and the ability to adapt existing smooth drums to specific grooving requirements without extensive modifications, enhancing versatility and reducing capital expenditure.

- Simulation and Digital Twins: Advanced simulation software (Finite Element Analysis - FEA) is increasingly used in the design phase to predict drum behavior under various load conditions, optimize material usage, and test different groove profiles virtually. The concept of digital twins – virtual models that mirror physical assets – is also gaining traction, allowing for continuous optimization and predictive maintenance throughout the drum's lifecycle.

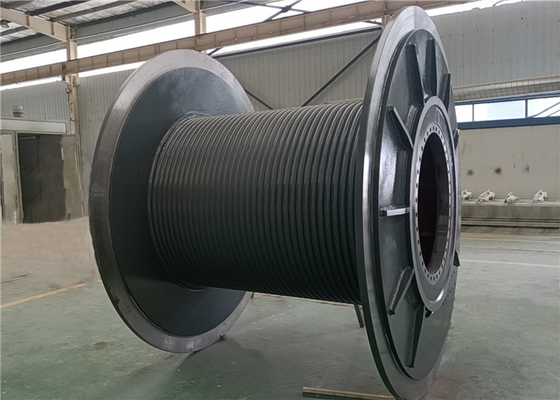

Image: High-precision manufacturing for advanced grooved drum systems.

Versatile Applications and Unrivaled Advantages of Grooved Drums

The inherent benefits of precision-engineered grooved drums make them indispensable across a vast array of industrial applications where reliable rope handling is critical. Their ability to ensure level winding, reduce rope wear, and enhance safety translates into significant operational advantages in diverse sectors.

Applicable Industries and Scenarios:

- Oil & Gas (Onshore & Offshore): From drilling rigs and workover rigs to offshore platforms and subsea intervention systems, grooved drums are essential for hoisting drill pipes, casing, and managing umbilical cables. The harsh marine environment often necessitates corrosion-resistant materials and coatings.

- Mining: Critical for mine hoists, winches for material transport, and deep shaft operations. Here, the emphasis is on robustness, high load capacity, and extreme durability to withstand abrasive conditions and continuous operation.

- Marine & Offshore: Used extensively in shipboard cranes, offshore mooring winches, tugboats, and research vessels. Applications include anchor handling, towing, and lifting operations, demanding excellent corrosion resistance and reliability.

- Construction: Found in tower cranes, mobile cranes, pile drivers, and hoists used for lifting heavy construction materials. Precision winding is crucial for safety and efficiency on construction sites.

- Material Handling: In large-scale warehouses, manufacturing plants, and logistics hubs, grooved drums are integral to overhead cranes, gantry cranes, and automated storage and retrieval systems (AS/RS). They ensure smooth, precise movement of goods.

- Metallurgy: Steel mills and metal processing plants utilize grooved drums in overhead cranes for moving heavy ladles, coils, and ingots, where high temperatures and extreme loads are common.

- Ports and Harbors: For large container111 cranes (STS, RTG, RMG), where precision and speed in handling massive loads are paramount.

- Hydropower and Water Treatment: In gate hoists for dams, sluices, and water treatment plants, controlling water flow and managing heavy gates. Emphasis on corrosion resistance and long service life due to constant exposure to water.

Technical Advantages in Typical Applications:

- Extended Wire Rope Life: The primary advantage. By guiding each layer of rope precisely, grooved drums (especially those with Lebus grooving) prevent pinching, crushing, and uneven wear. This can extend rope life by 200-500% compared to smooth drums, drastically reducing replacement costs and downtime.

- Enhanced Operational Safety: Consistent rope spooling eliminates erratic winding patterns that can lead to sudden load shifts, rope entanglement, or even catastrophic failure. This significantly improves safety for personnel and equipment.

- Improved Winding Efficiency: Precise grooves ensure that the rope lays perfectly, layer upon layer, minimizing the energy required for winding and unwinding. This leads to energy savings, especially in systems with high duty cycles. For instance, in a typical crane operation, a properly designed grooved drum can contribute to up to 10-15% energy efficiency improvement due to reduced friction and smooth operation.

- Reduced Maintenance and Downtime: With less rope wear and fewer winding issues, the frequency of rope inspection, repair, and replacement is significantly reduced. This translates directly into lower maintenance costs and increased operational uptime.

- Corrosion Resistance: For industries like marine, petrochemical, and water treatment, the selection of corrosion-resistant materials (e.g., stainless steel, specialized coatings) is critical. A well-engineered grooved drum can withstand harsh chemical exposure and saline environments, ensuring long-term integrity.

- Optimized Space Utilization: Efficient layering of rope allows for a more compact drum design for a given rope capacity, which is crucial in space-constrained applications.

Image: A customized steel grooved drum designed for specific industrial requirements.

Technical Specifications and Performance Parameters of Grooved Drums

Understanding the detailed technical specifications of a grooved drum is crucial for procurement and operational planning. The following table outlines typical parameters that define the performance and suitability of these critical components.

Typical Grooved Drum Parameters:

| Parameter | Description | Typical Range / Value | Impact on Performance |

|---|---|---|---|

| Drum Material | Forged Steel (e.g., 42CrMo, 35CrMo), Cast Iron, Stainless Steel | Varies by application (e.g., Steel for high load, SS for corrosion) | Determines strength, wear resistance, corrosion resistance, and overall lifespan. |

| Drum Diameter (Flange OD) | Outer diameter of the drum flanges. | 300 mm - 5000 mm (12 in - 200 in) | Influences rope bending fatigue, rope capacity, and system size. |

| Drum Length (Grooved Part) | Length of the section containing grooves. | 200 mm - 3000 mm (8 in - 120 in) or customized | Directly impacts the number of rope layers and total rope capacity. |

| Rope Diameter (D) | Nominal diameter of the wire rope. | 6 mm - 80 mm (0.24 in - 3.15 in) | Critical for matching groove profile and ensuring proper rope fit. |

| Groove Type | Lebus, Helical, Random | Lebus (most common for precise layering) | Determines rope winding pattern, efficiency, and life. Lebus offers superior winding. |

| Groove Pitch | Distance between centers of adjacent grooves. | Typically 1.05 D to 1.15 D | Ensures optimal spacing for rope layers, prevents pinching. |

| Effective Drum Core Diameter | Diameter at the bottom of the grooves. | Minimum 18D (for hoist applications) | Influences rope bending fatigue and theoretical load capacity. |

| Load Capacity | Maximum static or dynamic load the drum can withstand. | 1 Ton - 500 Tons (or higher for custom) | Primary indicator of the drum's strength and application suitability. |

| Surface Hardness | After heat treatment (e.g., induction hardening). | HRC 45-55 (for hardened areas) | Directly impacts wear resistance and drum service life. |

| Inspection Standards | Industry standards for manufacturing and testing. | ISO, ANSI, ASTM, DIN, API, DNV, ABS, LR | Ensures quality, safety, and interoperability. |

| Estimated Service Life | Under normal operating conditions and proper maintenance. | 15 - 30+ Years (for well-maintained, quality drums) | Long-term cost-effectiveness and ROI. |

Manufacturer Comparison: Choosing the Right Grooved Drum Partner

Selecting a manufacturer for grooved drums goes beyond just product specifications; it involves assessing their expertise, quality control, customization capabilities, and after-sales support. The market for grooved drums and related solutions, such as groove drums, includes a range of providers from large industrial conglomerates to specialized boutique manufacturers.

| Category of Manufacturer | Key Characteristics | Pros | Cons | Best Suited For |

|---|---|---|---|---|

| Large OEMs / Industrial Conglomerates | Broad product lines, integrated solutions, global presence, high production volume. | Extensive R&D, brand recognition, global support network, often part of larger systems. | Less flexibility for niche customization, higher overheads leading to higher standard pricing, longer lead times for custom orders. | Standardized large-scale projects, clients prioritizing established brands and integrated solutions. |

| Specialized Grooved Drum Manufacturers (e.g., LBS Winch) | Focused expertise in winch components, high degree of customization, advanced engineering. | Deep technical knowledge, rapid prototyping, highly tailored solutions (e.g., Grooved Drum Skin Drum Winch Cover Grooved Sleeves), stringent quality control specific to drums, competitive pricing for custom work. | May not offer full winch systems, less global physical presence (rely on distributors/direct shipping). | Clients needing specific groove types, unique load capacities, specialized materials, or innovative solutions like drum sleeves; those prioritizing performance and customization. |

| Budget/Mass Production Suppliers | Primarily focus on cost efficiency, standard designs, high volume production. | Lower initial cost, readily available stock for common sizes. | Limited customization, potentially lower quality control, shorter service life, higher long-term maintenance costs. | Cost-sensitive projects with less stringent performance requirements, non-critical applications. |

For critical industrial applications, partnering with a specialized manufacturer like LBS Winch for your grooved drum or groove sleeves ensures access to deep engineering expertise, adherence to rigorous quality standards, and the flexibility to provide highly customized solutions that precisely match unique operational demands. This focus translates into superior product performance, extended operational life, and a strong return on investment.

Customization and Innovative Solutions: Grooved Sleeves for Smooth Drums

While integrated grooved drums are ideal for new installations, many existing winch systems utilize smooth drums, which can lead to premature wire rope wear and winding inconsistencies. This is where innovative solutions like the Grooved Drum Skin Drum Winch Cover Grooved Sleeves For Smooth Drum come into play. These modular sleeves allow for a cost-effective upgrade, transforming a standard smooth drum into a highly efficient grooved system without the need for complete drum replacement.

Image: Lebus groove sleeve offering a modular upgrade for smooth winch drums.

The Advantage of Grooved Sleeves:

- Cost-Effectiveness: Significantly lower capital expenditure compared to replacing the entire drum assembly.

- Reduced Downtime: Installation is often quicker and less disruptive than a full drum replacement.

- Enhanced Performance: Instantly upgrades a smooth drum to the benefits of a precision-grooved system, extending rope life and improving safety.

- Versatility: Available in various materials (steel, nylon, custom alloys) and groove profiles to match specific rope diameters and applications. They can be split or solid, depending on installation requirements.

Customization Process for Grooved Drums and Sleeves:

Leading manufacturers offer comprehensive customization services, recognizing that off-the-shelf solutions may not always meet unique operational demands. A typical customization process involves:

- Detailed Consultation: Understanding the specific application, winch type, wire rope characteristics (diameter, construction, breaking strength), environmental conditions, load cycle, and desired service life.

- Engineering Design and Simulation: Utilizing CAD/CAM software and FEA (Finite Element Analysis) to design the optimal drum or sleeve, considering factors like material stress, fatigue, and heat dissipation.

- Material Selection: Recommending the most suitable material (e.g., specific alloy steel, stainless steel for marine, specialized polymers for sleeves) and heat treatment processes to meet performance and longevity requirements.

- Groove Profile Optimization: Tailoring the Lebus or helical groove profile for maximum rope life and winding efficiency for the specified rope and application.

- Surface Treatment and Coatings: Applying specialized surface treatments (e.g., induction hardening, chrome plating, ceramic coatings) to enhance wear resistance, corrosion resistance, or reduce friction as needed.

- Integrated Components: Designing drums to seamlessly integrate with existing shafts, bearings, gearboxes, and braking systems.

- Quality Assurance and Documentation: Providing comprehensive test reports, material certificates, and compliance documentation (e.g., DNV, ABS, LR, ISO).

Image: Steel or nylon split Lebus sleeve, adaptable for various winch drum configurations.

Case Studies: Grooved Drums in Action

The practical impact of high-quality grooved drums is best illustrated through real-world applications. These case studies highlight how precision engineering translates into tangible benefits for complex industrial operations.

Case Study 1: Enhanced Deepwater Mooring System for Offshore Platform

- Challenge: An existing semi-submersible offshore platform experienced frequent wire rope damage and replacement on its mooring winches, leading to costly downtime and safety concerns. The original smooth drums contributed significantly to premature rope wear under heavy loads and constant dynamic motion in deepwater conditions.

- Solution: The operator decided to upgrade to specialized grooved drums (or groove sleeves applied to existing drums) with a Lebus pattern, manufactured from marine-grade alloy steel and featuring enhanced induction hardening and anti-corrosion coatings. The drums were custom-engineered for 76mm diameter synthetic and steel hybrid mooring lines.

- Outcome:

- Wire Rope Life Extension: Average rope life increased by approximately 300%, from 1.5 years to over 4.5 years, directly attributable to precise spooling and reduced inter-layer crushing.

- Reduced Downtime: Maintenance intervals for rope inspection and replacement were significantly extended, saving an estimated $500,000 per year in operational costs and vessel downtime.

- Improved Safety: Eliminating erratic winding reduced risks associated with fouled lines and improved overall operational safety.

Case Study 2: Optimization of Overhead Crane for Heavy Steel Coil Handling

- Challenge: A major steel mill's overhead cranes, tasked with moving 50-ton steel coils, experienced rapid wear of wire ropes and occasional load swinging due to inconsistent winding on their existing smooth hoist drums. This impacted efficiency and posed safety risks in a high-temperature, high-load environment.

- Solution: The mill replaced its smooth hoist drums with high-capacity grooved drums engineered from heat-treated alloy steel (e.g., 35CrMo), featuring robust Lebus grooving optimized for their 32mm steel wire ropes.

- Outcome:

- Increased Rope Service Life: Wire rope replacement frequency dropped by 60%, from every 6 months to 15 months, leading to substantial savings on rope procurement and installation labor.

- Enhanced Operational Smoothness: The consistent winding pattern significantly reduced load swinging, improving control and safety during coil transfers, which contributed to a 5% increase in operational throughput.

- Reduced Maintenance: Less friction and wear on ropes also reduced stress on other hoist components, decreasing overall maintenance requirements for the crane system.

Case Study 3: Modernizing a Water Treatment Plant Gate Hoist

- Challenge: A municipal water treatment plant utilized an aging gate hoist with a smooth drum for controlling a large sluice gate. Exposure to treated water and varying humidity caused accelerated corrosion on the drum surface and premature failure of the wire ropes due to inconsistent winding.

- Solution: The plant opted for custom-designed grooved drums made from stainless steel (SS316L) with an additional marine-grade epoxy coating for enhanced corrosion resistance. The Lebus grooving was designed for optimal winding of their 20mm galvanized steel ropes.

- Outcome:

- Elimination of Corrosion Issues: The stainless steel construction and specialized coating completely halted the previous corrosion problems, ensuring the drum's structural integrity over the long term.

- Extended Component Life: The wire rope life more than doubled, and the overall service life of the grooved drum is projected to exceed 25 years, minimizing future replacement needs.

- Improved Reliability: Consistent and smooth operation of the sluice gate improved the plant's operational reliability and reduced manual intervention.

Image: A high-performance grooved drum exemplifying reliability in a demanding application.

Commitment to Quality, Support, and Trustworthiness

In B2B partnerships, trust is built on proven quality, reliable support, and clear commitments. A reputable supplier of grooved drums and related components like the Grooved Drum Skin Drum Winch Cover Grooved Sleeves For Smooth Drum will stand by their products and services.

Certifications and Quality Assurance:

Adherence to international standards is a non-negotiable aspect of high-quality grooved drum manufacturing. Look for manufacturers with:

- ISO 9001: Certification for Quality Management Systems, ensuring consistent product quality and customer satisfaction.

- Classification Society Approvals: For marine and offshore applications, certifications from bodies like DNV (Det Norske Veritas), ABS (American Bureau of Shipping), Lloyd's Register (LR), or Bureau Veritas are essential. These signify compliance with rigorous industry-specific safety and performance standards.

- API Specifications: For oil and gas industry components, adherence to American Petroleum Institute (API) standards (e.g., API 2C for offshore pedestal cranes) demonstrates suitability for demanding environments.

- Comprehensive Testing: Beyond standard NDT (Non-Destructive Testing), manufacturers should provide material certificates, heat treatment reports, and dimensional inspection reports for every grooved drum.

Frequently Asked Questions (FAQ):

- Q: How does a grooved drum extend wire rope life?

- A: The precisely machined grooves ensure the wire rope spools uniformly layer upon layer, preventing crushing, pinching, and random overlapping that are common causes of premature wear on smooth drums. This controlled winding significantly reduces bending fatigue and abrasion, dramatically increasing the wire rope's operational life.

- Q: Can I upgrade my existing smooth drum to a grooved drum?

- A: Yes, innovative solutions like Grooved Drum Skin Drum Winch Cover Grooved Sleeves For Smooth Drum are specifically designed for this purpose. These split or solid sleeves can be fitted over existing smooth drums, providing the benefits of Lebus grooving without requiring a full drum replacement, making it a cost-effective upgrade.

- Q: What is the typical lead time for a custom grooved drum?

- A: Lead times vary depending on the drum's complexity, material requirements, size, and current production schedules. For a highly customized grooved drum, typical lead times can range from 8 to 16 weeks, including design, manufacturing, and rigorous testing. Standard or semi-custom options may have shorter lead times.

- Q: What warranty is typically offered on a grooved drum?

- A: Reputable manufacturers typically offer a warranty period of 12 to 24 months from the date of delivery or commissioning, covering manufacturing defects and material failures under normal operating conditions. Specific terms will be outlined in the sales agreement.

- Q: How do I determine the correct grooved drum for my application?

- A: This requires a detailed assessment of your winch's capacity, target load, wire rope diameter and type, desired rope length, operating environment (temperature, corrosion risk), and duty cycle. It is highly recommended to consult with the manufacturer's engineering team, who can provide expert guidance and customize a solution to your precise needs.

Delivery and Customer Support:

- Global Logistics: Experienced manufacturers provide robust packaging and efficient global shipping solutions, including sea freight and air cargo, ensuring safe and timely delivery to even the most remote industrial sites.

- Technical Assistance: Post-sale support, including installation guidance, operational troubleshooting, and maintenance recommendations, is crucial for maximizing the lifespan and performance of your grooved drum.

- Long-Term Partnership: A focus on building enduring relationships, offering spare parts, and providing ongoing consultancy for future projects reinforces trust and ensures continuous operational excellence.

Image: Commitment to quality is evident in every aspect of a grooved drum's production.

Conclusion: Investing in Superior Grooved Drum Technology

The choice of a grooved drum is a strategic decision that profoundly impacts the efficiency, safety, and longevity of critical lifting and pulling operations. From the meticulous manufacturing processes involving forging, CNC machining, and advanced heat treatments, to the precise engineering of groove profiles like Lebus, every aspect contributes to superior performance.

Investing in high-quality grooved drums or innovative solutions like Grooved Drum Skin Drum Winch Cover Grooved Sleeves For Smooth Drum is not merely an expenditure but a long-term investment that yields substantial returns through extended wire rope life, reduced maintenance costs, enhanced operational safety, and increased system uptime. As industries continue to evolve, the demand for precision, durability, and customization in components like grooved drums will only grow, underscoring their irreplaceable role in the backbone of industrial infrastructure.

Partnering with a specialized manufacturer that embodies expertise, experience, authoritativeness, and trustworthiness—as demonstrated through stringent quality control, industry certifications, and comprehensive customer support—ensures that your industrial operations are equipped with the most reliable and efficient rope management solutions available. The future of industrial lifting and pulling depends on the continued advancement and meticulous application of grooved drum technology.

References

- ISO 4301-1: Cranes -- Classification -- Part 1: General classification, International Organization for Standardization.

- API Specification 2C: Offshore Pedestal-Mounted Cranes, American Petroleum Institute.

- DNV GL Rules for Classification of Ships.

- British Standard BS 7262: Code of practice for the safe use of cranes.

- Wire Rope Technical Board Handbook.

- ASME B30.2: Overhead and Gantry Cranes (Top Running Bridge, Single or Multiple Girder, Top Running Trolley Hoist).

- The Lebus Principle and Its Application to Wire Rope Spooling, Lebus International Engineers, Inc. Technical Papers.

Previous

This is the first article-

Customized Marine Winches for Business RequirementsNewsJul.31,2025

-

Customized Single Drum Hoist Winches with BearingsNewsJul.31,2025

-

Innovative Grooved Split Drum Electric Mooring Winch SolutionsNewsJul.31,2025

-

Oxygen-Free Carburized Bevel Gears for MachineryNewsJul.31,2025

-

Multi-layer Winding Metal Cable Drums for RopesNewsJul.31,2025

-

S355J2+N Marine Winch Rope Drums for Large SizesNewsJul.31,2025