Durable Winch Drum for Industrial Lifting & Pulling

Navigating Industrial Lifting: The Evolution and Significance of the Winch Drum

In heavy industries ranging from marine and offshore operations to construction, mining, and material handling, the reliable and efficient movement of heavy loads is paramount. At the heart of most lifting and pulling systems lies the winch drum, a critical component responsible for coiling and deploying wire ropes or synthetic lines. Its design, material integrity, and precision engineering directly dictate the safety, efficiency, and longevity of the entire winch mechanism. The modern industrial landscape demands components that not only meet stringent performance criteria but also offer enhanced durability, reduced maintenance, and optimal energy consumption. Current industry trends reflect a strong shift towards intelligent automation, integrating advanced sensor technologies, variable speed drives, and remote monitoring capabilities, which in turn necessitate winch drums designed for smoother operation, less wear on ropes, and compatibility with sophisticated control systems. Furthermore, there is an increasing emphasis on sustainable manufacturing practices and the use of corrosion-resistant materials, particularly in harsh environments like marine or petrochemical applications. This comprehensive understanding of the winch drum, its associated technologies, and the intricate manufacturing processes ensures that businesses can make informed decisions when investing in robust lifting solutions.

The demand for specialized winches, such as the double drum winch, is also on the rise, particularly in applications requiring independent control over multiple lines or extended rope capacities. These systems often feature complex gearing and control architectures that require an exceptionally robust winch drum capable of handling high loads, precise coiling, and dynamic operational stresses. The integration of advanced materials like high-strength alloy steels and sophisticated surface treatments ensures that these drums can withstand abrasive forces and environmental degradation over extended service lives, thereby reducing downtime and operational costs. The core challenge for manufacturers lies in balancing superior mechanical properties with cost-effectiveness and adherence to international safety standards, including ISO 9001 for quality management and specific industry certifications like API for oil and gas, DNV GL for marine, and various regional safety directives. Addressing these evolving requirements demands a deep technical expertise and a proactive approach to research and development, continuously pushing the boundaries of material science and manufacturing precision to deliver next-generation lifting solutions.

Precision Engineering: The Manufacturing Journey of a Winch Drum

The manufacturing of a high-performance winch drum is a meticulously engineered process, beginning with the selection of premium materials chosen for their specific mechanical properties, such as tensile strength, yield strength, ductility, and fatigue resistance. Common materials include various grades of cast iron (e.g., QT600-3, HT200), carbon steels (e.g., Q345B, Q235B), and alloy steels (e.g., 42CrMo), with stainless steel used for highly corrosive environments. The initial phase often involves either casting or forging. Casting, particularly sand casting or centrifugal casting, is suitable for complex geometries and large-scale production, allowing for the creation of intricate internal structures and rope grooves. Forging, conversely, imparts superior mechanical properties by refining the grain structure, enhancing strength and toughness, which is critical for drums subjected to extreme loads and dynamic stresses. After the primary shaping, the drums undergo extensive CNC (Computer Numerical Control) machining, ensuring precise dimensions, concentricity, and the accurate formation of rope grooves, such as the critical Lebus (LBS) groove system, which ensures optimal rope layering and minimizes wear.

Subsequent stages in the manufacturing process include heat treatment, such as quenching and tempering, to further enhance the material's hardness, wear resistance, and overall mechanical performance. This step is crucial for increasing the service life of the winch drum, particularly in demanding applications where continuous operation and high-stress cycles are common. Surface finishing treatments, like shot peening, galvanizing, or specialized coatings, are applied to protect against corrosion, abrasion, and fatigue, significantly extending the drum's operational lifespan in challenging environments like marine or offshore platforms. Throughout the entire manufacturing journey, rigorous quality control and inspection standards are strictly adhered to. These include non-destructive testing (NDT) methods like ultrasonic testing (UT), magnetic particle inspection (MPI), and radiographic testing (RT) to detect any internal flaws or surface imperfections. Furthermore, dimensional checks, material composition analysis (e.g., spectroscopy), and mechanical property testing (e.g., tensile tests, hardness tests) are performed to ensure compliance with international standards such as ISO (International Organization for Standardization), ANSI (American National Standards Institute), API (American Petroleum Institute), DNV GL, and ABS (American Bureau of Shipping). This comprehensive quality assurance regimen guarantees that each winch drum component meets the highest benchmarks for safety, reliability, and performance, delivering tangible advantages like reduced maintenance costs, enhanced operational efficiency, and superior resistance to harsh conditions, contributing to significant energy savings through optimized rope layering and reduced friction.

Technical Parameters and Key Specifications of Winch Drums

Understanding the technical parameters of a winch drum is fundamental for proper selection and integration into any industrial lifting system. These specifications directly influence the drum's compatibility with wire ropes, its load-bearing capacity, and overall operational efficiency. Key parameters include the drum diameter, which affects the rope speed and the number of layers a rope can spool, and the drum length, which determines the total rope capacity. The choice of material, as previously discussed, is dictated by the operating environment and required load, with cast iron and various steel alloys being common. Rope groove types are critical for optimal rope management; smooth drums are simplest but can lead to uneven layering, while helical grooves, especially Lebus (LBS) grooving, ensure precise multi-layer spooling, significantly extending rope life and preventing crushing or snarling, a critical aspect for applications requiring continuous, high-volume operation like that of a double drum winch or a standard drum winch. The safe working load (SWL) is a paramount safety parameter, indicating the maximum load the drum is designed to handle under specified conditions.

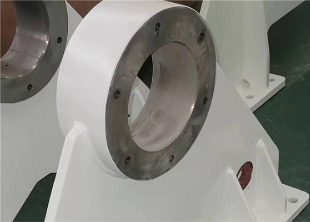

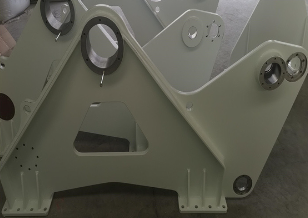

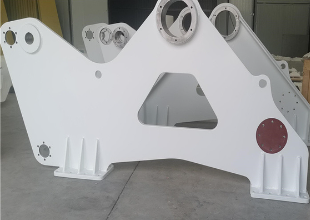

Surface treatments such as painting, galvanizing, or specialized coatings are applied to enhance corrosion resistance and reduce friction, thereby increasing the durability and efficiency of the winch drum. For complex winch systems, the integration of components like specialized brackets and bearings is crucial; for instance, the "For Winch Rope Lifting And Down Marine Winch Accessories Bracket-Bearing" product from LBSWinch exemplifies a high-quality accessory designed to support the smooth operation of the winch rope, minimizing friction and wear on both the rope and the drum while ensuring precise alignment during lifting and lowering operations, especially vital in marine environments where consistent performance is critical. Manufacturing processes, including casting, forging, welding, and advanced CNC machining, ensure dimensional accuracy and material integrity. Adherence to international standards like ISO, ANSI, API, and various classification society rules (e.g., DNV GL, ABS) is not just a regulatory requirement but a guarantee of quality, safety, and interoperability across global operations. The table below provides a representative overview of typical technical parameters for industrial winch drums, offering a clear reference for procurement and engineering teams evaluating options for their specific project needs, underscoring the importance of selecting a drum that aligns perfectly with operational demands and environmental conditions to maximize performance and safety.

Typical Winch Drum Technical Parameters

| Parameter | Typical Range/Options | Significance |

|---|---|---|

| Material | Cast Iron (QT600-3, HT200), Carbon Steel (Q345B, Q235B), Alloy Steel (42CrMo), Stainless Steel | Determines strength, wear resistance, and corrosion resistance. |

| Drum Diameter (D) | 150mm - 2500mm (6 inches - 98 inches) | Influences rope speed and bending stress on the wire rope. |

| Drum Length (L) | 300mm - 4000mm (12 inches - 157 inches) | Dictates total rope storage capacity. |

| Rope Diameter | 6mm - 100mm (0.24 inches - 4 inches) | Must match groove size for optimal rope performance. |

| Groove Type | Smooth, Helical (LBS groove - single layer, multi-layer) | Affects rope layering, wear, and system stability. LBS groove improves rope life by 500%. |

| Safe Working Load (SWL) | 1 Ton - 500 Tons | Maximum operational load; crucial for safety and compliance. |

| Surface Treatment | Painting, Galvanizing, Electroplating, Specialized Coatings | Enhances corrosion resistance and friction reduction. |

| Manufacturing Process | Casting, Forging, Welding, CNC Machining, Heat Treatment | Ensures dimensional accuracy, material integrity, and mechanical properties. |

| Applicable Standards | ISO, ANSI, API, DNV GL, ABS, CCS, Lloyd's Register | Guarantees quality, safety, and regulatory compliance. |

Diverse Applications and Sector-Specific Advantages of Winch Drums

The versatility and robustness of the winch drum make it an indispensable component across a wide array of demanding industrial sectors, each with unique operational requirements and environmental challenges. In the marine and offshore industry, including shipping, oil rigs, and subsea operations, winch drums are critical for mooring, towing, anchor handling, and deploying subsea equipment. Here, anti-corrosion properties and high fatigue resistance are paramount due to exposure to saltwater and extreme weather, making drums made from specially treated alloy steels or stainless steel with marine-grade coatings essential. For the oil and gas sector, particularly for drilling and well intervention, winch drums must handle enormous loads and precise depth control, often requiring multi-layer Lebus grooving for optimal wire rope management and extended service life. Mining operations rely on heavy-duty winch drums for hoisting, hauling, and conveying materials, where extreme abrasion and impact resistance are key, often necessitating drums forged from high-strength steels with robust heat treatments.

In the construction industry, particularly for cranes and material lifts, winch drums facilitate the precise positioning of heavy structural components and equipment, where smooth operation and reliable braking mechanisms are critical for safety and efficiency. The petrochemical and chemical processing industries demand winch drum components that can withstand corrosive chemicals and high temperatures, often requiring specialized coatings and materials like stainless steel to prevent degradation and ensure operational integrity. For municipal applications such as water treatment and sewage systems, corrosion-resistant drums are vital for deploying and retrieving pumps and maintenance tools within harsh, often acidic or alkaline, environments. In the metallurgy sector, especially steel mills, winch drums are integral to moving heavy billets, coils, and slag pots, operating under extreme temperatures and dusty conditions, necessitating materials with exceptional heat resistance and mechanical strength. Across all these industries, the technical advantages of a well-engineered winch drum are evident: enhanced safety through precise rope management, reduced operational costs due to extended component and rope lifespan, and improved energy efficiency from optimized spooling. Our drum winch and double drum winch solutions are specifically designed with these sector-specific challenges in mind, offering unparalleled reliability and performance as evidenced by numerous successful deployments and positive customer feedback in demanding applications worldwide, showcasing our commitment to delivering tailored and high-performing solutions for diverse industrial needs.

Selecting the Right Partner: Manufacturer Comparison and Custom Solutions

Choosing the right manufacturer for your winch drum needs is as crucial as the technical specifications themselves, directly impacting the long-term reliability, support, and overall value of your investment. While many suppliers offer standard winch components, leading manufacturers distinguish themselves through a combination of engineering expertise, manufacturing precision, adherence to international standards, and a robust commitment to customer service and customization. Key differentiators often include the depth of their R&D capabilities, their track record in complex projects, and their ability to provide tailored solutions for highly specialized applications, such as large-scale marine towing or unique industrial processes requiring a bespoke double drum winch system. A comprehensive evaluation should consider factors like material sourcing, in-house manufacturing capabilities (e.g., advanced CNC machining, heat treatment facilities), quality assurance protocols, and the availability of certification from reputable classification societies.

At LBSWinch, our commitment to excellence is reflected in our robust manufacturing processes, extensive engineering support, and our ability to deliver highly customized winch drum solutions that precisely meet client specifications. Our "For Winch Rope Lifting And Down Marine Winch Accessories Bracket-Bearing" product exemplifies our dedication to precision engineering, providing essential support for critical marine winch operations, ensuring longevity and reliability in harsh conditions. Unlike competitors who might offer limited off-the-shelf options, we specialize in designing and manufacturing custom winch drums with specific dimensions, materials, groove types (including advanced LBS grooving for optimal rope layering), and surface treatments, tailored for unique load capacities and operational environments. Our engineering team collaborates closely with clients from concept to completion, utilizing advanced CAD/CAM software and finite element analysis (FEA) to simulate performance and ensure structural integrity under anticipated loads. This bespoke approach ensures that whether you require a compact drum winch or a multi-ton double drum winch, the final product is optimized for performance, safety, and longevity, often exceeding industry benchmarks. The table below illustrates a comparative overview, highlighting the critical aspects that differentiate top-tier manufacturers in the industrial winch component market, showcasing LBSWinch’s leadership in quality, customization, and comprehensive technical support.

Manufacturer Comparison: Key Differentiators for Winch Drum Suppliers

| Feature/Attribute | LBSWinch | Competitor A (Standard) | Competitor B (Value-focused) |

|---|---|---|---|

| Customization Capability | Extensive (Bespoke designs, materials, grooves, sizes) | Limited (Standard modifications only) | Minimal (Primarily off-the-shelf) |

| Engineering & Design Support | Full lifecycle support, FEA, CAD/CAM integration | Basic consultation for standard products | Post-sale technical sheet only |

| Quality Certifications | ISO 9001, API, DNV GL, ABS, CCS, Lloyd's (project-specific) | ISO 9001 (Basic) | No specific external certifications |

| Material Traceability | 100% certified from reputable mills with full documentation | Standard mill certificates | Basic material declaration |

| After-Sales Support | Comprehensive (Technical assistance, parts, warranty, training) | Limited (Parts only) | Minimal (Online FAQ only) |

| Typical Lead Time (Custom) | 6-12 weeks (optimized for project complexity) | 10-20 weeks (less flexible) | 12-24 weeks (less predictable) |

Ensuring Reliability: Quality Assurance, Certifications, and Support

The unwavering commitment to quality assurance and adherence to international certifications are cornerstones of reliable winch drum manufacturing. These processes instill confidence in clients by guaranteeing that every component meets rigorous safety, performance, and environmental standards. Our quality management system is certified to ISO 9001, providing a robust framework for consistent product quality and continuous improvement across all stages, from design and material procurement to manufacturing, testing, and delivery. For specific industry applications, our winch drums comply with highly specialized regulations and classification society rules. For instance, in marine and offshore applications, our products can be certified by DNV GL, ABS, Lloyd's Register, or CCS, ensuring compliance with stringent maritime safety and operational guidelines, critical for any drum winch or double drum winch used in these environments. Similarly, for the oil and gas sector, adherence to API standards (e.g., API Spec 2C for offshore cranes) ensures that winch components are fit for purpose in highly demanding and potentially hazardous operations.

Beyond initial certifications, our dedication to trustworthiness extends to comprehensive post-sales support and clear operational guarantees. We provide detailed documentation, including material certificates, NDT reports, and performance test data, ensuring complete transparency and traceability for every winch drum. Our standard delivery cycle for custom winch drums typically ranges from 6 to 12 weeks, depending on complexity and material availability, with expedited options available for urgent projects. Each product is backed by a comprehensive warranty, typically ranging from 12 to 24 months, covering manufacturing defects and ensuring peace of mind for our clients. Our customer support team is readily available to provide technical assistance, troubleshooting, and spare parts procurement, ensuring minimal downtime and sustained operational efficiency. We have a proven track record of resolving complex technical challenges and providing timely support, as demonstrated by numerous successful service cases where our rapid response and expert intervention kept critical operations running smoothly. Our commitment to unparalleled service, combined with our rigorous quality controls, reinforces our position as a trusted partner for mission-critical industrial lifting solutions, providing unparalleled reliability for your winch systems, including the crucial bracket-bearing component that ensures the stability and longevity of your winch operations.

Frequently Asked Questions (FAQ) about Winch Drums

To further enhance understanding and address common inquiries regarding the selection, application, and maintenance of winch drum components, we've compiled a list of frequently asked questions. These questions cover critical aspects that B2B decision-makers and technical personnel often consider when procuring or integrating winch solutions, ensuring clarity and transparency in our offerings.

Q1: What are the primary factors to consider when selecting a winch drum material?

The primary factors for material selection for a winch drum include the maximum load capacity, the operating environment (e.g., marine, corrosive chemicals, high temperatures), and the required service life. High-strength alloy steels like 42CrMo are preferred for heavy-duty applications requiring superior wear and fatigue resistance. For highly corrosive environments, stainless steel or carbon steel with specialized coatings (like galvanizing or marine-grade paints) are essential. Cast iron (e.g., QT600-3) offers good vibration dampening and cost-effectiveness for moderate loads, while forged steel provides exceptional strength and toughness for critical applications. Understanding the specific operational stresses and environmental exposure is crucial for making an informed material choice that ensures both performance and longevity, directly impacting the overall operational cost and safety profile of the entire winch system, including accessories like bracket-bearings.

Q2: How does LBS grooving benefit the performance and lifespan of a wire rope and the winch drum?

Lebus (LBS) grooving is a specialized system that ensures controlled, multi-layer spooling of wire rope on a winch drum, significantly enhancing both performance and lifespan. Unlike conventional smooth drums or simple helical grooves, LBS grooving forces the rope into a precise, organized pattern layer after layer, preventing crushing, uneven winding, and kinks that lead to premature rope failure. This optimized spooling distributes the load evenly across the drum surface, reduces localized stress points on the rope, and minimizes abrasive wear on both the rope and the drum itself. Studies show that LBS grooving can extend wire rope life by up to 500% compared to smooth drums, leading to substantial cost savings from reduced rope replacement and minimized downtime. This precision also improves the overall stability and safety of lifting operations, especially for systems like a double drum winch where synchronized and precise rope handling is critical, preventing potential snags and ensuring smooth load ascent and descent.

Q3: What certifications should I look for when sourcing a winch drum for marine applications?

For marine applications, rigorous certifications from recognized classification societies are essential for a winch drum to ensure compliance with international maritime safety regulations and operational standards. Key certifications to look for include DNV GL (Det Norske Veritas Germanischer Lloyd), ABS (American Bureau of Shipping), Lloyd's Register, Bureau Veritas, and CCS (China Classification Society). These certifications confirm that the drum's design, materials, manufacturing process, and testing adhere to the highest industry benchmarks for safety, reliability, and environmental compatibility in harsh marine environments. Beyond these, a manufacturer's ISO 9001 quality management system certification is also crucial, demonstrating a consistent commitment to quality throughout the entire production cycle. Verifying these certifications ensures that the winch drum will perform reliably under the demanding conditions of marine lifting and pulling operations, safeguarding personnel and assets.

Q4: Can LBSWinch provide customized winch drums for unique project requirements?

Absolutely. LBSWinch specializes in providing highly customized winch drum solutions tailored to unique project requirements. We understand that standard off-the-shelf components may not always meet the specific demands of complex industrial applications. Our experienced engineering team works closely with clients to develop bespoke designs based on specific load capacities, rope diameters, drum dimensions, groove patterns (including specialized multi-layer Lebus grooving), material requirements (e.g., specific alloy steels, stainless steel), and surface treatments. We leverage advanced design tools like CAD/CAM and finite element analysis (FEA) to ensure optimal performance, structural integrity, and compliance with all relevant industry standards. Whether you need a unique drum winch for a specialized industrial process or a custom double drum winch for large-scale synchronized operations, our capabilities allow us to deliver precision-engineered solutions that integrate seamlessly into your existing or new systems, ensuring maximum efficiency and reliability for your critical lifting and pulling operations.

References

- American Petroleum Institute (API) Standards for Offshore Drilling and Production.

- International Organization for Standardization (ISO) 9001: Quality Management Systems.

- DNV GL: Rules for Classification of Ships and Offshore Units.

- American Bureau of Shipping (ABS) Guide for Certification of Lifting Appliances.

- The Lebus Engineering Handbook: Wire Rope Spooling Technology.

Previous

This is the first article-

Customized Marine Winches for Business RequirementsNewsJul.31,2025

-

Customized Single Drum Hoist Winches with BearingsNewsJul.31,2025

-

Innovative Grooved Split Drum Electric Mooring Winch SolutionsNewsJul.31,2025

-

Oxygen-Free Carburized Bevel Gears for MachineryNewsJul.31,2025

-

Multi-layer Winding Metal Cable Drums for RopesNewsJul.31,2025

-

S355J2+N Marine Winch Rope Drums for Large SizesNewsJul.31,2025