Durable Grooved Winch Drums for Optimal Wire Spooling

Understanding the Critical Role of Grooved Winch Drums in Heavy-Duty Operations

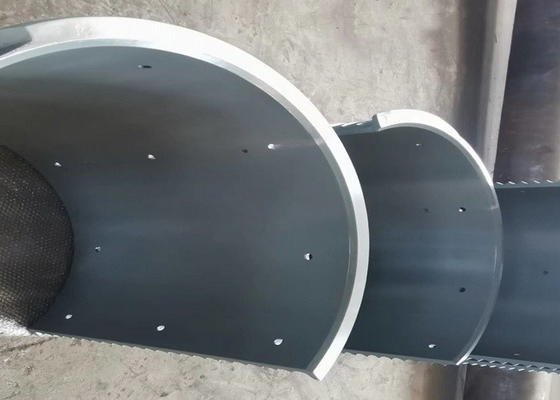

In industries demanding precision, safety, and durability for material handling and lifting, the grooved winch drum stands as a cornerstone component. Unlike conventional smooth drums, grooved drums are engineered with helical or parallel grooves that meticulously guide wire rope, ensuring uniform spooling, minimizing wear, and significantly extending the lifespan of the rope itself. This advanced design is paramount in applications where heavy loads, high speeds, and repetitive cycles are the norm, contributing directly to operational efficiency and safety across diverse sectors. Its importance cannot be overstated in modern industrial infrastructure.

The escalating demand for more reliable and efficient lifting solutions has pushed manufacturers to innovate, focusing on materials science and precision engineering. This evolution addresses critical challenges such as fatigue, corrosion, and operational safety, leading to the development of highly specialized drums. Our focus on the Alloy Steel Anchor Drum Winch Cover grooved winch drum exemplifies this commitment to excellence, offering a product tailored for the most demanding marine and industrial environments. Its superior design and construction underscore a strategic advantage for any operation seeking to optimize its winching systems.

The Advanced Manufacturing Process of Grooved Winch Drums

The production of a high-performance grooved winch drum is a sophisticated process, integrating advanced metallurgy with precision engineering. The journey begins with the selection of premium materials, primarily high-grade alloy steels such as 42CrMo, 35CrMo, or Q345B, chosen for their exceptional tensile strength, wear resistance, and fatigue properties. These materials undergo rigorous testing to meet international standards, including ISO 9001 and ANSI specifications, ensuring their suitability for demanding applications. The choice of material directly impacts the drum's longevity and performance under extreme conditions, highlighting the critical nature of this initial phase.

Precision Manufacturing Stages: From Forging to Finishing

- Material Preparation & Forging: Large steel ingots are heated and forged to achieve a dense, uniform grain structure, enhancing mechanical properties. Forging eliminates internal defects and improves material integrity, which is crucial for the drum's structural soundness.

- Rough Machining & Heat Treatment: The forged blank undergoes rough machining to achieve initial dimensions. This is followed by specialized heat treatments, such as quenching and tempering, to optimize hardness, toughness, and stress relief. These thermal processes are precisely controlled to imbue the alloy steel with its superior performance characteristics.

- CNC Grooving: The most critical phase involves high-precision CNC machining to cut the specific helical or parallel grooves. Utilizing advanced multi-axis CNC lathes, this process ensures exact groove profiles, pitch, and depth, critical for optimal rope spooling. The accuracy of the grooving directly influences wire rope longevity and operational efficiency.

- Surface Treatment & Finishing: Post-grooving, drums often receive surface treatments like polishing, coating, or nitriding to enhance corrosion resistance and reduce friction. This step is particularly vital for drums operating in harsh marine or chemical environments, significantly extending their operational lifespan.

- Quality Inspection: Each grooved winch drum undergoes a series of stringent quality checks, including ultrasonic testing for internal defects, magnetic particle inspection for surface cracks, dimensional accuracy checks, and material hardness tests. This comprehensive inspection regime guarantees compliance with global safety and performance benchmarks, such as API Q1 and DNV GL standards, ensuring the product's reliability in critical applications.

The meticulous attention to detail at each stage of manufacturing ensures that the resulting grooved winch drum not only meets but often exceeds the demanding requirements of industries like petrochemical, metallurgy, mining, and water treatment. Products like the Alloy Steel Anchor Drum Winch Cover Grooved Winch Drum are designed for a service life often exceeding 20 years with proper maintenance, showcasing their robust engineering. In typical applications, these drums significantly reduce energy consumption due to smoother rope handling and offer exceptional resistance to corrosion, even in aggressive environments, proving their value as a long-term investment.

Technical Specifications and Performance Metrics

Selecting the appropriate grooved winch drum requires a detailed understanding of its technical parameters and how they align with operational demands. Key specifications dictate performance, safety, and compatibility within a given system. The Alloy Steel Anchor Drum Winch Cover Grooved Winch Drum, for instance, is designed with a specific set of parameters to ensure optimal performance in marine anchoring and heavy lifting operations. Understanding these figures is crucial for engineers and procurement specialists looking to acquire the best solution for their needs. Prospective clients often want to know exactly what they are investing in, making transparent data essential.

Key Parameters for Grooved Winch Drums

| Parameter | Typical Range / Value | Significance |

|---|---|---|

| Drum Material | Alloy Steels (e.g., 42CrMo, 35CrMo, Q345B) | Determines strength, wear resistance, and corrosion properties. Critical for durability. |

| Rope Diameter Range | 2mm to 80mm (Customizable) | Defines compatibility with various wire ropes. Must match application needs. |

| Drum Diameter | 200mm to 2000mm (or larger) | Influences rope capacity, winding ratio, and overall winch footprint. |

| Groove Type | Lebus Grooving (Parallel & Helical), Helical | Affects rope spooling accuracy, layer separation, and minimizes cross-over. Lebus is preferred for multi-layer spooling. |

| Rope Capacity | Up to 10,000m (depending on drum size & rope dia.) | Maximum length of wire rope the drum can accommodate. Critical for operational reach. |

| Design Standards | API, ISO, ANSI, DNV GL, Lloyd's Register | Ensures compliance with industry safety, quality, and performance benchmarks. |

| Surface Hardness | HB 220-280 (Post-treatment) | Indicates resistance to abrasion and indentation, extending drum life. |

These specifications underline the precision and performance expected from a high-quality grooved winch drum. For example, a Lebus grooving system is critical for multi-layer spooling, preventing crushing and minimizing wear, thereby significantly enhancing wire rope life by up to 500% compared to smooth drums. This directly translates into reduced maintenance costs and improved operational uptime. Companies seeking to buy grooved winch drum solutions must prioritize these technical merits to ensure long-term value and operational safety.

Diverse Application Scenarios and Industry Trends

The versatility of the grooved winch drum allows its deployment across a broad spectrum of industries, each benefiting from its precise rope management capabilities. From deep-sea exploration to heavy industrial lifting, these drums are indispensable. In the marine sector, they are crucial for anchor handling, towing, and offshore drilling platforms, where robust and reliable equipment is non-negotiable due to harsh environmental conditions. The ability to manage long lengths of wire rope with minimal wear is a significant advantage in these applications, ensuring operational continuity and safety for personnel.

Industry-Specific Applications and Emerging Trends

- Oil & Gas (Offshore & Onshore): Used in drilling rigs, pipe-laying vessels, and mooring systems for reliable heavy lifting and precise positioning of equipment. The demand for deeper exploration and production drives the need for high-capacity, durable drums capable of handling extreme loads and environmental pressures.

- Mining: Essential for hoisting systems in underground and open-pit mines, where safety and continuous operation are paramount. Modern trends lean towards automated systems requiring even greater precision in rope spooling.

- Construction: Employed in large cranes, pile drivers, and bridge construction, facilitating the lifting and movement of heavy structural components. Urbanization and infrastructure development continue to fuel demand for robust lifting solutions.

- Water Treatment & Petrochemical: Utilized in processes requiring precise control of valves, gates, or submerged equipment. Resistance to corrosive elements and longevity are key considerations in these environments, making alloy steel drums highly valuable.

- Marine & Ports: Beyond anchor drums, they are vital for cargo handling cranes, ship-to-shore gantry cranes, and specialized research vessels. The trend towards larger vessels and faster turnaround times demands more efficient and robust winching mechanisms.

Current industry trends indicate a strong move towards automation, remote operation, and increased data integration for predictive maintenance. This necessitates grooved winch drum designs that can integrate seamlessly with advanced control systems, offering feedback on rope tension, speed, and positioning. Furthermore, the emphasis on sustainability and environmental protection means a greater focus on energy-efficient designs and materials with a longer lifespan, reducing waste and operational footprints. Manufacturers that offer highly customizable solutions and comprehensive support are increasingly favored by companies looking to buy grooved winch drum systems that are future-proof.

Customization and Engineered Solutions

Recognizing that no two industrial applications are identical, leading manufacturers of grooved winch drum solutions offer extensive customization options. This bespoke approach ensures that each drum is perfectly aligned with the client's specific operational requirements, optimizing performance and extending component life. Customization can involve adjustments to drum dimensions, material specifications, groove profiles (e.g., Lebus parallel or helical), surface treatments, and integration features. For instance, an offshore drilling platform might require a drum designed to handle extreme tensions and corrosive saltwater environments, necessitating specific alloy compositions and anti-corrosion coatings. This level of tailored engineering is crucial for complex projects.

Designing for Specific Needs

- Material Selection: Beyond standard alloy steels, specialized materials like stainless steel or duplex alloys can be used for highly corrosive environments. This choice impacts both initial cost and long-term maintenance.

- Groove Design Optimization: Tailoring the Lebus system or helical grooving for specific rope types (e.g., fiber rope vs. steel wire rope) and spooling capacities (e.g., 30m to 1000m capacity, 80 layers). This ensures perfect rope lay and minimizes fleet angle issues.

- Integrated Sensor Systems: Incorporating sensors for real-time monitoring of rope tension, speed, and position, providing critical data for predictive maintenance and operational safety. This is a growing trend in high-tech applications.

- Modular Design: For larger drums, a split design (e.g., split Lebus sleeves) allows for easier installation, maintenance, and replacement, reducing downtime and logistical complexities.

The ability to provide engineering drawings, simulation results, and material certifications (e.g., from DNV GL, ABS, BV) ensures that custom solutions meet the highest safety and performance benchmarks. Companies looking to buy grooved winch drum solutions for unique or challenging applications should prioritize manufacturers with a proven track record in custom engineering and a comprehensive understanding of diverse industry requirements. This collaborative approach between client and manufacturer leads to truly optimized and reliable winching systems, delivering superior return on investment.

Ensuring Reliability: Quality Assurance and After-Sales Support

The longevity and performance of a grooved winch drum are inextricably linked to the manufacturer's commitment to quality assurance and robust after-sales support. Reputable suppliers adhere to stringent international standards, such as ISO 9001 for quality management systems, ensuring consistent product quality from raw material sourcing to final inspection. Certifications from classification societies like DNV GL, Lloyd's Register, American Bureau of Shipping (ABS), and Bureau Veritas (BV) provide independent verification of product design, manufacturing quality, and adherence to maritime or industrial regulations. These certifications are often non-negotiable for critical applications, offering an assurance of quality to the end-user.

Comprehensive Support Throughout the Product Lifecycle

- Testing and Verification: Each grooved winch drum undergoes rigorous testing, including non-destructive testing (NDT) like ultrasonic and magnetic particle inspection, hardness tests, and dimensional checks. Load tests and functional performance evaluations ensure that the drum meets or exceeds specified operational parameters before shipment.

- Warranty and Guarantee: A standard warranty period, typically 12-24 months from delivery or commissioning, underscores the manufacturer's confidence in their product. This provides peace of mind for clients investing in high-value components.

- Delivery Cycle: A transparent and efficient supply chain is crucial. Manufacturers should provide clear estimates on lead times, from design approval to fabrication and delivery, typically ranging from 8-16 weeks for custom orders, depending on complexity and size.

- Technical Support and Spare Parts: Ongoing technical support, including troubleshooting assistance, installation guidance, and the readily availability of genuine spare parts (e.g., drum sleeves, bearings), is vital for maximizing uptime and extending the drum's service life. Companies that buy grooved winch drum solutions from reputable vendors benefit from this long-term partnership.

- Client Feedback Integration: Leading manufacturers actively seek and integrate client feedback into their R&D processes, demonstrating a commitment to continuous improvement and addressing real-world operational challenges. This iterative process ensures products remain at the forefront of industry demands.

The commitment to quality, backed by comprehensive certifications and proactive client support, differentiates top-tier manufacturers. Choosing a supplier with a robust quality assurance framework and a reputation for excellent post-sales service is just as important as the product's technical specifications when considering where to buy grooved winch drum components for critical industrial applications. This holistic approach ensures long-term operational efficiency and safety.

Frequently Asked Questions (FAQ) about Grooved Winch Drums

-

Q1: What are the primary advantages of a grooved winch drum over a smooth drum?

A1: The main advantages include superior wire rope management, significantly extending rope life by minimizing crushing, kinking, and uneven spooling. Grooved drums ensure consistent and predictable rope layers, reducing friction and wear, which smooth drums cannot achieve, especially in multi-layer applications. This translates to enhanced safety, reduced downtime, and lower operational costs due to less frequent rope replacement.

-

Q2: How does Lebus grooving improve performance for a grooved winch drum?

A2: Lebus grooving is a specialized parallel grooving system where the rope enters the drum at one end and is guided precisely in parallel layers, then crosses over to the next layer at a specific point. This system prevents crushing and ensures even distribution of tension across the rope layers, dramatically increasing wire rope life and stability, especially for long lengths and multi-layer spooling. It's considered the industry standard for high-performance winches.

-

Q3: What materials are typically used for high-quality grooved winch drum manufacturing?

A3: High-quality drums are typically manufactured from robust alloy steels such as 42CrMo, 35CrMo, or Q345B, chosen for their superior strength, wear resistance, and fatigue properties. For highly corrosive environments, specialized stainless steel or duplex alloys might be used. The material selection is critical to ensure the drum's longevity and performance under specific operational stresses and environmental conditions.

-

Q4: Can a grooved winch drum be customized for specific applications?

A4: Yes, customization is a key service offered by leading manufacturers. Drums can be tailored in terms of dimensions (diameter, length), groove profile, material composition, surface treatments, and integration features to meet unique operational requirements, load capacities, and environmental conditions. This ensures optimal performance and seamless integration into existing or new winch systems. It is recommended to consult with engineers when you look to buy grooved winch drum with custom requirements.

-

Q5: What certifications should I look for when purchasing a grooved winch drum?

A5: Look for manufacturers adhering to international quality management standards like ISO 9001. Additionally, product-specific certifications from classification societies such as DNV GL, ABS, Lloyd's Register, or Bureau Veritas are strong indicators of quality and compliance with rigorous industry standards, particularly important for marine and offshore applications. These certifications provide assurance of design integrity and manufacturing excellence.

Conclusion: Investing in Superior Winch Drum Technology

The Alloy Steel Anchor Drum Winch Cover grooved winch drum represents a significant leap forward in winching technology, offering unparalleled precision, durability, and operational efficiency. Its sophisticated design, coupled with advanced manufacturing processes and stringent quality control, ensures reliability in the most challenging industrial and marine environments. For decision-makers and technical personnel, understanding the detailed specifications, application benefits, and the underlying engineering excellence is paramount when considering to buy grooved winch drum solutions.

The investment in a high-quality grooved drum translates directly into extended wire rope life, reduced maintenance costs, enhanced safety protocols, and improved operational uptime. As industries continue to evolve towards more demanding and precise operations, the role of a well-engineered grooved winch drum will only grow in importance, solidifying its position as a critical component for safe and efficient heavy-duty lifting and material handling.

References

- Technical Guidelines for Wire Rope Spooling Systems in Heavy Industry.

- Advanced Materials Science in Marine and Offshore Equipment Manufacturing.

- Comparative Analysis of Grooved vs. Smooth Drums in Crane Operations.

- The Impact of Precision Engineering on Wire Rope Lifespan: A Study on Lebus Grooving.

- International Standards and Certifications for Lifting Equipment Components.

Previous

This is the first article-

Customized Marine Winches for Business RequirementsNewsJul.31,2025

-

Customized Single Drum Hoist Winches with BearingsNewsJul.31,2025

-

Innovative Grooved Split Drum Electric Mooring Winch SolutionsNewsJul.31,2025

-

Oxygen-Free Carburized Bevel Gears for MachineryNewsJul.31,2025

-

Multi-layer Winding Metal Cable Drums for RopesNewsJul.31,2025

-

S355J2+N Marine Winch Rope Drums for Large SizesNewsJul.31,2025