Double Drum Mooring Winch - Heavy-Duty, Synchronized Control

Double Drum Mooring Winch is a key solution in the Machinery and equipment industry, specifically within Lifting and transportation equipment and winch. This article explores how Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Double Drum Mooring Winch Overview

- Benefits & Use Cases of Double Drum Mooring Winch in winch

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in Machinery and equipment

- Conclusion on Double Drum Mooring Winch from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

Double Drum Mooring Winch Overview

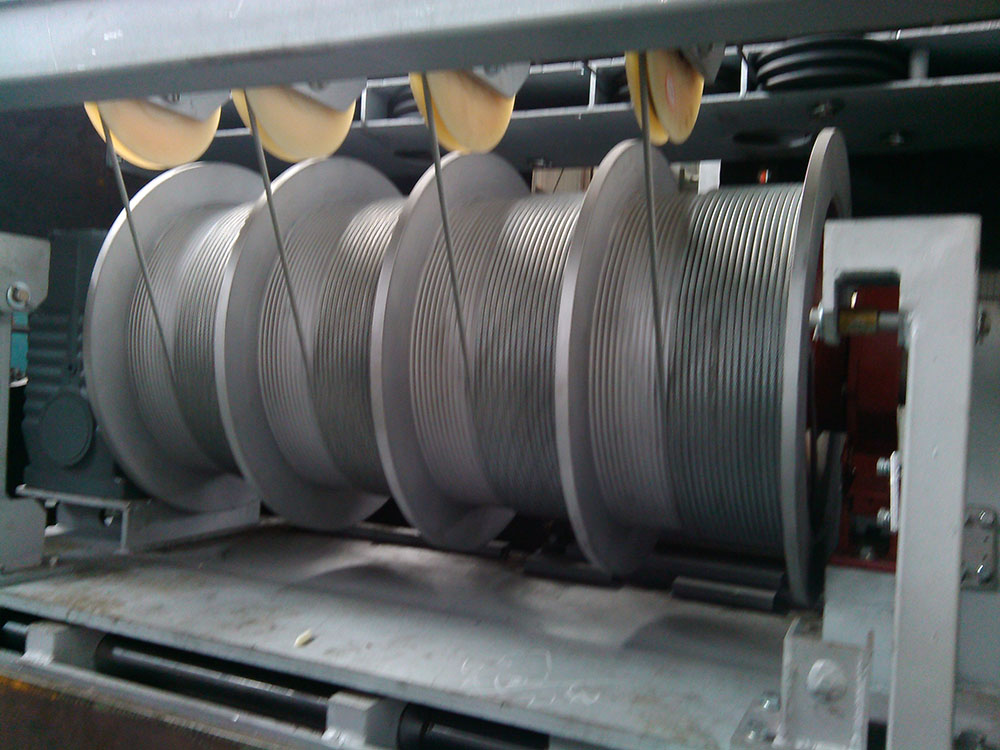

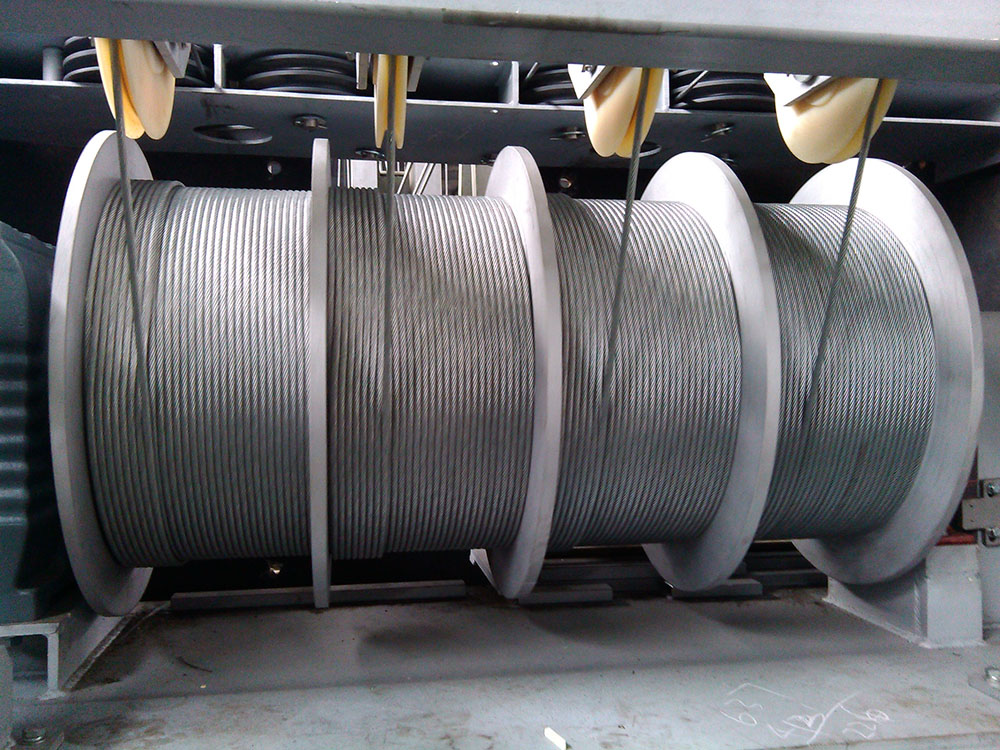

A Double Drum Mooring Winch is engineered with two synchronized or independently controlled drums to handle complex mooring, positioning, and lifting tasks on vessels, offshore platforms, and industrial sites. In the Lifting and transportation equipment segment, this configuration provides operational flexibility—operators can work with separate lines for port and starboard, or run in tandem for balanced line pull and improved control. Typical configurations include electric or hydraulic power, fail-safe brakes, clutches, local/remote controls, and LEBUS-style grooved drums to optimize multi-layer spooling and extend wire rope life.

Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. designs and builds robust dual drum winch systems with configurable line pull (for example, 10–200 kN), variable line speed, marine-grade coatings, and class-compliant options (upon request) for DNV/ABS/CCS. For special applications such as a double drum winch for high mast maintenance, the company integrates precise synchronization and overload protection to ensure safe raising/lowering cycles. Their manufacturing strength in grooved drum technology helps reduce crushing and slippage on multi-layer wraps—translating to longer rope service and smoother operations for B2B operators.

Benefits & Use Cases of Double Drum Mooring Winch in winch

In port terminals and on deck, a Double Drum Mooring Winch supports fast line handling, constant tension modes for surge compensation, and reliable holding power in dynamic environments. Offshore platforms benefit from dual-drum redundancy for station-keeping and barge mooring, while civil and industrial sites deploy the configuration for synchronized lifts and positioning tasks. The setup also suits lighting and infrastructure projects—a double drum winch for high mast systems can lift and lower assemblies safely, with balanced loads and precise control.

- Key features: LEBUS-grooved drums for superior spooling, heavy-duty bearings, sealed braking systems, variable speed drives, and optional constant tension/auto-tension control.

- Competitive advantages: improved rope lifespan, fewer interventions, better deck layout efficiency, and integration-ready controls (PLC/HMI/remote).

- Junzhong expertise: Decades of application engineering in marine and industrial winch projects, from standard dual drum winch packages to custom, class-ready builds tailored to B2B specifications.

Cost, Maintenance & User Experience

For B2B buyers, the total cost of ownership (TCO) extends far beyond the purchase price. With a Double Drum Mooring Winch from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd., value is delivered via robust construction, corrosion-resistant finishes, and optimized spooling that can significantly extend wire rope life—reducing consumable spend and downtime. Electric versions paired with variable-frequency drives help cut energy consumption and deliver smoother ramp-up/ramp-down, while hydraulic models offer high power density for heavy-duty cycles.

- Durability and ROI: Heavy-duty gear trains, fail-safe brakes, and grooved drums reduce shock loads and wear; users report fewer rope changes and lower maintenance frequency over multi-year service windows.

- Maintenance: Clear service points, guarded rotating parts, accessible brake linings, and standardized components ease periodic inspections and parts replacement.

- User feedback: Port operators and industrial clients cite improved line handling, more predictable tension control, and higher availability—key contributors to lower lifecycle costs and faster payback.

Sustainability & Market Trends in Machinery and equipment

Global ports and offshore operators are prioritizing energy efficiency, safety, and digital readiness. Electrification is accelerating, favoring variable-speed electric winches that reduce energy peaks and noise. Where hydraulics are preferred, eco-friendly fluids and leak-prevention measures are increasingly standard. Class and regulatory expectations are also tightening, influencing choices around braking redundancy, emergency stops, and remote diagnostics—areas where a modern Double Drum Mooring Winch can deliver measurable improvements.

- Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. supports these trends with high-efficiency motors, advanced controls, and durable coatings (e.g., C5M marine environments) to extend asset life and reduce environmental impact.

- Forward-thinking designs include data-ready control panels, optional remote monitoring, and precise tension control to reduce rope waste and extend component lifecycles—practical sustainability that lowers TCO.

Conclusion on Double Drum Mooring Winch from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

A Double Drum Mooring Winch remains a strategic asset for marine, offshore, and industrial operators seeking safer, faster, and more economical line handling. By combining LEBUS-style grooved drums, precise controls, and rugged construction, Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. delivers dependable performance for both standard mooring and specialized tasks like high mast operations. Partner with a manufacturer that understands uptime, compliance, and lifecycle economics.

- Unlock the value of modern winch technology in the Machinery and equipment / Lifting and transportation equipment / winch category.

- Trust the engineering and service reputation of Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

- Contact us: email: lbswinch@lebus.com.cn — Visit our website: https://www.lbswinch.com

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025