Double Drum Electric Winch - Heavy-Duty, Precise Sync

A Field Note on the Double Drum Electric Winch Trend

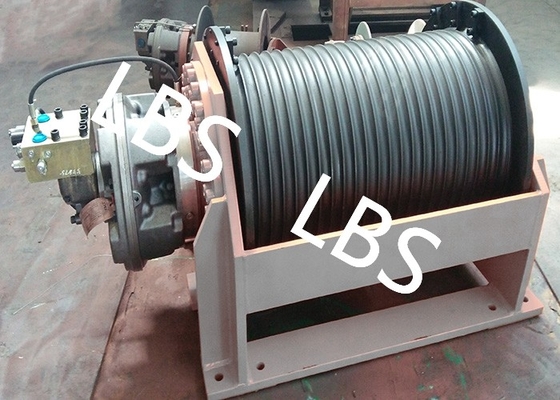

If you work around nets, moorings, or barge decks, you’ve probably noticed the quiet rise of modern, compact winches. The LBS grooved drum system caught my eye years ago; to be honest, it looked like a niche trick. It isn’t. The way it manages rope spooling — avoiding bite-in and allowing, in practice, many layers — has become a real-world differentiator. Many customers say it’s the first time their wire rope behaved the same on the fifth layer as on the first.

What’s moving the market

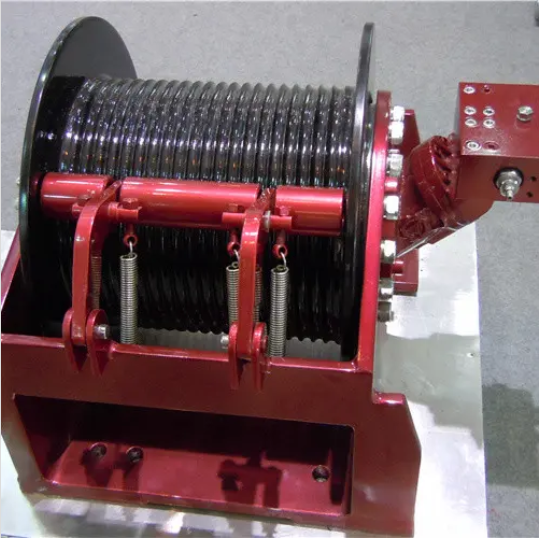

Electrification (even 12V DC on small craft), smarter spooling geometries, sealed gearboxes, and VFD-ready motors are now table stakes. Surprisingly, the hot topic in trawler groups isn’t raw pull; it’s consistent retrieval speed and tidy winding under variable loads. The Double Drum Electric Winch format also reduces cycle time — one drum pays out while the other recovers.

Key specifications (typical, configurable)

| Product name | Fishing Net Drum Winch Electric Double Drum Winch 12V Drum Winch Motor |

| Voltage | 12V DC (other voltages on request) |

| Line pull (rated) | ≈ 0.5–10 t (custom builds possible; real-world use may vary) |

| Line speed | ≈ 10–60 m/min, depending on ratio and drum layer |

| Drum system | LBS grooved drum; controlled spooling to mitigate rope bite-in |

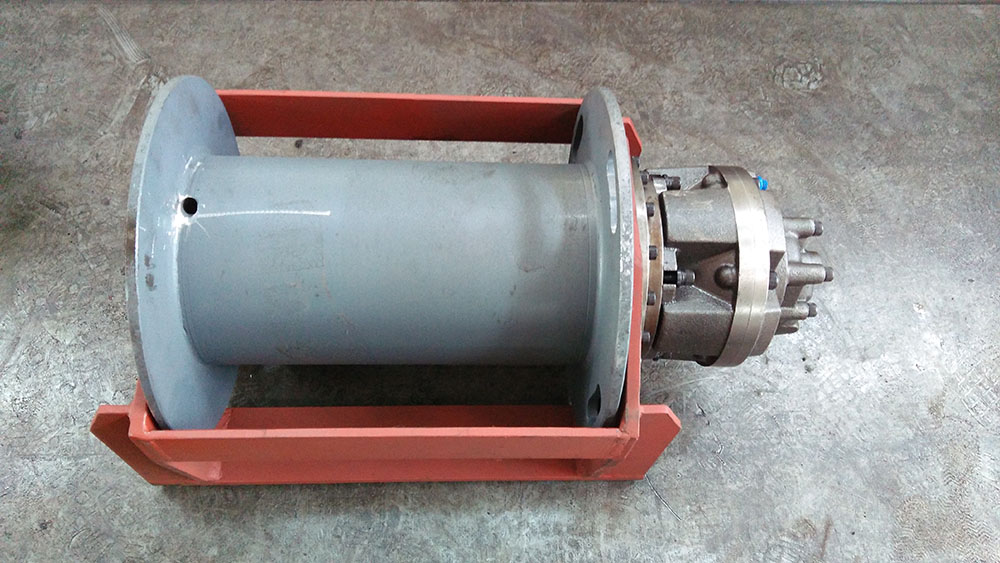

| Materials | Welded steel drum and frame; marine epoxy coating; sealed bearings |

| FOB reference | US $0.5–9,999 / piece (MOQ ≈100; scope-dependent) |

| Origin | NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China |

Process, testing, and service life

Build flow usually goes: cut and roll drum shells → CNC groove finishing (LBS profile) → weld and stress-relieve frame → gearbox/motor alignment → electrical integration → proof load test. Typical checks reference ISO 4301/4309 for lifting classification and wire-rope care; motors are validated per IEC 60034. Factory proof loads are commonly 110–125% SWL, with brake holding tests on both drums. Service life? I guess 8–15 years is realistic with rope inspection and annual grease/paint touch-ups.

Where it’s used

- Trawlers and purse seiners: net hauling, paravane handling.

- Aquaculture: cage tending, moor line work.

- Ports and yards: pull-in, positioning, maintenance lifts (within rating).

- Construction and mining: utility pulls where dual-drum payoff helps.

Vendor snapshot (quick compare)

| Vendor | Core tech | Customization | Certs (on request) | Lead time | Notes |

|---|---|---|---|---|---|

| LBS (Shijiazhuang) | LBS grooved drums | High (drum, ratio, voltage) | ISO/SGS, CE/ABS per project | Around 3–6 weeks | FOB pricing band listed; origin verified |

| Generic A | Standard grooves | Medium | CE, basic ISO | 4–8 weeks | Budget-focused |

| Generic B | Plain drum | Low | Limited | 2–4 weeks | Fast but fewer options |

Customization and feedback

Options tend to include rope type (galv. wire or HMPE), drum width/diameter, dual-speed, manual band brake, clutch, remote pendant, and IP rating. One fisheries manager told me, “We got steadier net retrieval, fewer kinked sections.” Another buyer mentioned quieter overnight sets — small detail, big morale boost.

A quick case

A 22 m trawler in the Yellow Sea swapped to a Double Drum Electric Winch with LBS grooves. Same crew, same nets; haul cycle dropped by ~12%, and post-shift rope inspections found notably less cross-layer imprinting. Not a lab result, but the skipper was grinning. Data point: factory proof at 125% SWL for 10 minutes; brake held both drums without drift.

Standards and documentation

Look for conformity to ISO 4309 for rope management, DNV/ABS guidance for marine lifting appliances, and IEC 60034 motor performance. Ask vendors to share test sheets and QA traceability; it seems boring, but it saves headaches.

References

- ISO 4309:2017 – Cranes — Wire ropes — Care and maintenance, inspection and discard

- DNV-ST-0378 – Standard for offshore and platform lifting appliances

- IEC 60034 – Rotating electrical machines (performance and testing)

- ABS Guide for the Certification of Lifting Appliances

- FEM 1.001/9.755 – Rules for the design of hoisting equipment

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025