Products

Grooved Drum Skin Drum Winch Cover Grooved Sleeves For Smooth Drum

Products Description

Profile

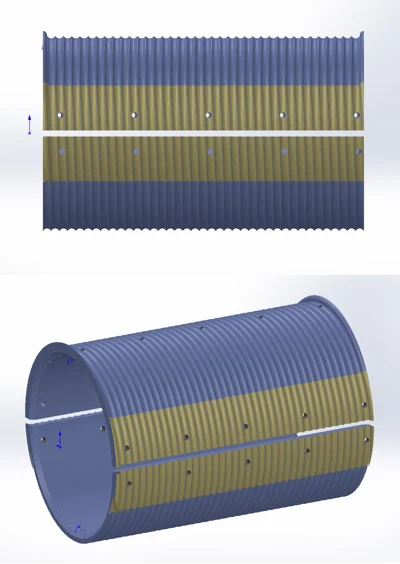

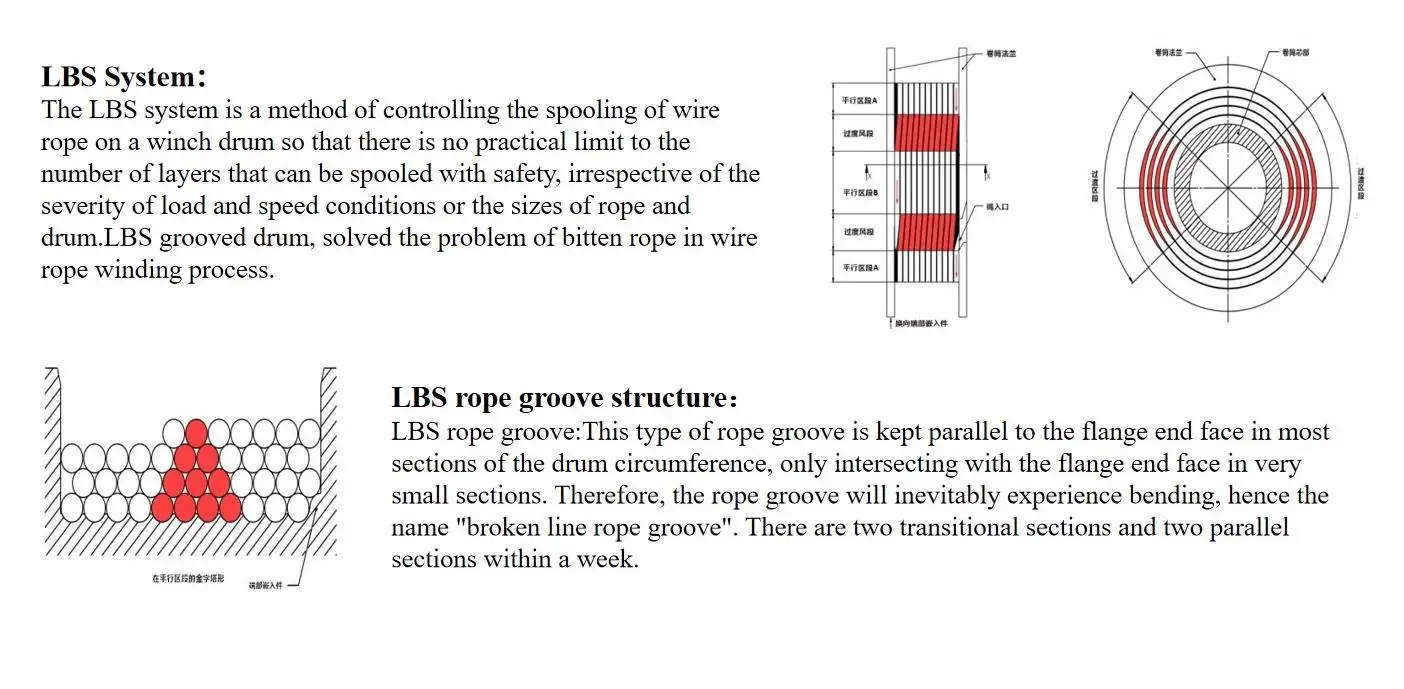

Split LBS rope groove drum skin: Process a smooth drum into a LBS rope groove structure, and then divide it into two pieces, each consisting of a section consisting of inclined rope grooves and parallel grooves. It can be installed on drums with smooth grooves or spiral grooves.

Split LBS rope groove leather: It is an effective and economical solution. If it is necessary to replace different types and sizes of ropes or damaged drums in the future, you can only replace the new LBS rope groove leather instead of replacing or repairing the entire drum component, saving costs for customers.

Integrated LBS rope groove drum: A drum with grooves directly inserted into it (with or without bolts or welding flanges as required). Process the LBS rope groove directly on the drum.

Advantages

In recent years, our products have been widely used in the fields of offshore platform cranes, oil workover drilling winches, logging rope winding equipment, wall wiping machine winches, helicopter motor winches, and so on. With its high reputation, high-quality products and service system, it has received widespread praise from domestic and foreign customers.

Technical Parameters

|

Product Basic Parameters(Specific specifications can be customized according to requirements):

|

|||

|

Product Name

|

Grooved Sleeves

|

Type Specification

|

LBSS-202310004

|

|

Byname

|

Grooved Drum Skin

|

Quality Assurance

|

1 year

|

|

Brand

|

LBS

|

Producing Area

|

Shijiazhuang, Hebei, China

|

|

Production Facility

|

CNC Center

|

Certification

|

ISO9001

|

|

Function

|

Winding, storing steel wire ropes

|

Applicable Equipment

|

Lifting or flat dragging of materials in construction, water conservancy projects, forestry, mines, docks, etc.

|

|

Color

|

Customized

|

MOQ

|

1 pcs

|

|

Material

|

Alloy steel(Customized)

|

Lifting Tonnage

|

20T

|

|

Rope Groove Type

|

Lebus

|

Rope Capacity

|

10-10000m

|

|

Rope Type

|

3-200mm

|

Power Source

|

Electric motor/Hydraulic motor

|

|

Maximum Lifting Height

|

10000m

|

Weight

|

200kg

|

|

Specific specifications can be discussed. Welcome to the news consultation!

|

|||

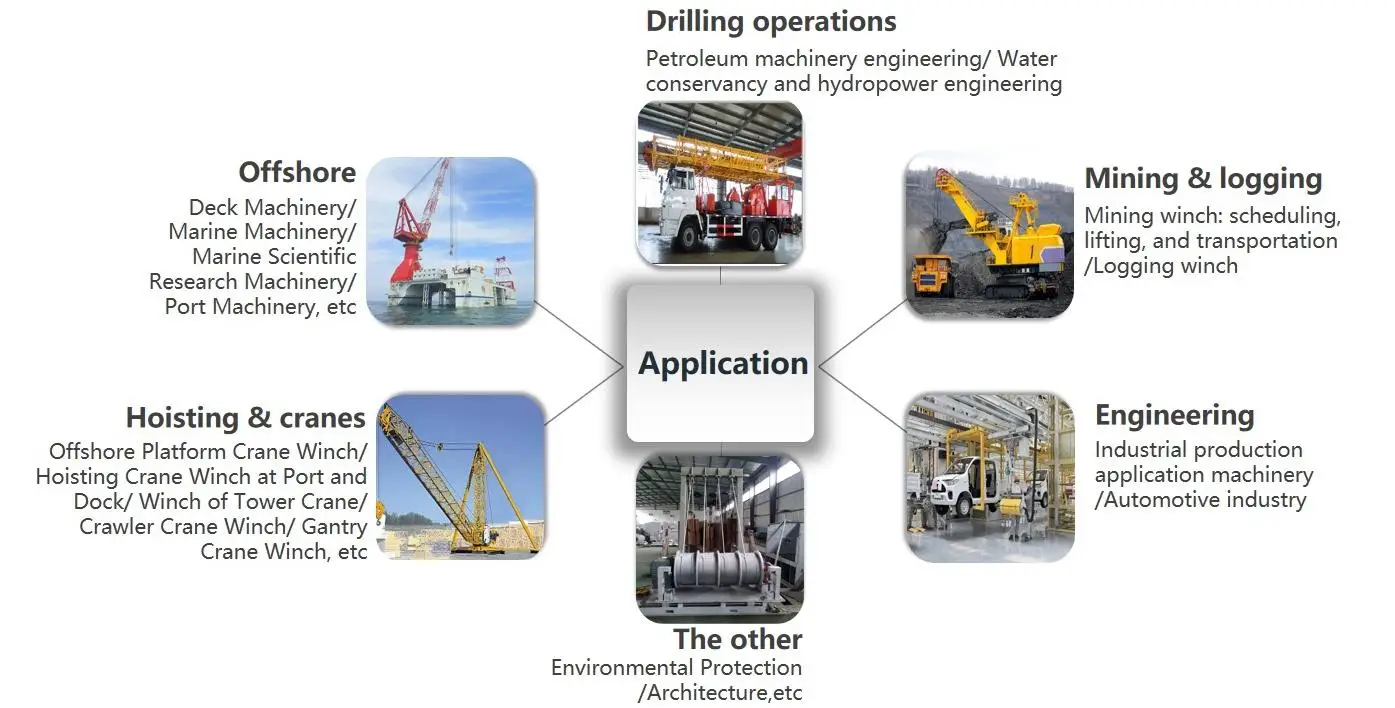

Application

The LBS series Grooved Sleeve is widely used in a variety of construction and engineering projects. These include water conservancy projects, forestry, mines, wharves, and more. It can be used effectively for material lifting or flat dragging. Additionally, it can be used as a auxiliary equipment for certain kinds of modern automated operations.

The LBS series Grooved Sleeve is driven by a gear reducer, which provides an efficient and reliable means of powering material hoists. As such, it is suitable for many different applications, such as civil construction and the installation of projects from construction and mining companies, and even factories.

|

Number

|

Rope Diameter(mm)

|

Rotation Direction

|

Drum Diameter(mm)

|

Drum Length(mm)

|

Application

|

|

1

|

13

|

Left

|

430

|

763

|

Oil Workover Rig And Oil Truck Drum

|

|

2

|

18

|

Left

|

623

|

1144

|

Oil Workover Rig And Oil Truck Drum

|

|

3

|

22 26

|

Left or Right

|

730

|

1120

|

Drilling Rig

|

|

4

|

18 22 32

|

Left or Right

|

670

|

1240

|

Windlass

|

|

5

|

28 32 36

|

Left or Right

|

560

|

630

|

Construction Machinery Rotary Drilling Rigs And Cranes

|

|

6

|

26 45

|

Left or Right

|

760 1146

|

1970 1765

|

Ocean Cranes, Docks

|

|

…

|

Support and Services

Products Technical Support and Service

We understand how important it is for our customers to have reliable technical support and service for their products. We are here to provide the best possible assistance when it comes to any questions or issues you may have. Our experienced team of experts is available to help you find the best solution for your needs. We offer a variety of technical support options, ranging from troubleshooting and installation to product advice and maintenance. Our technical support team is available 24 hours a day, 7 days a week to answer any questions you may have. In addition to our technical support services, we also provide a wide range of services to keep your products running efficiently and effectively. These services include regular maintenance, repair, and replacement. We can also provide assistance with customization and upgrades if necessary. We strive to provide the best possible technical support and service for our customers. We are committed to keeping your products running smoothly and efficiently. If you have any questions or issues, please do not hesitate to contact us. Our team of experts is here to help.

Processing Technic

Packing and Shipping

1.Each product is packed in a strong wooden boxes or pallets. 2.The box is labelled with the product details, such as the model number, and other relevant information. 3.We use reliable shipping providers to ensure that our Grooved Drum Sleeves reach their destination safely and on time.

Tips

FAQ

What products do you produce? Our main products include various types of winches, LBS groove drum, LBS sleeves, spooling device winch, petroleum drilling rig winch, trailer mounted pumping unit, crane winch, fifth wheel, Herringbone Gear,etc.

What are the areas of application for your products? Products are widely used in offshore platforms, ships, mines, petroleum, coal, ports, terminals, geological exploration, environmental protection, engineering machinery and other heavy machinery.

What technical parameters do customers need to provide? 1. Drum diameter: 2. Width between flanges: 3. Rope or cable diameter: 4. Length of rope or cable to be accommodated: 5. Distance to fixed sheave and position between flanges: 6. Direction of wire rope entry: 7. Outside diameter of flanges: 8. Maximum operating load on rope or cable: 9. Type of rope entry through flange or Through barrel: 10. Material and requirements of the drum 11. A detailed drawing of the drum if possible: 12. Any Further Information

Can I get a good price? Our products are reasonably priced to be cost-effective. Please send your inquiry to jzjxzz@LBS-china.com, or call +86-311-80761996, and we will reply to your request within 24 hours.

How shall I pay? T / T and L / C payments are workable for us.

How long does the delivery take from you? Delivery date depends on the model, specification and quantity required. When we make a quotation, we will separately state the delivery date. If you want an earlier delivery, we will try to make shift.

How will the goods be packed? Our products are generally packed in wooden cases.

How long is the warranty? The warranty starts from the date of BL (AWB) and lasts for 12 months.

Do you provide on-site installation and commissioning services? We can provide on-site installation and commissioning services according to your requirements. Details and pricing of the services will be subject to the specially signed foreign technical service contract.

If the product fails, how should we do? When failure occurs, please send a description of the failure in words and pictures to us. We will respond within 24 hours after receipt of your notice, and give solution proposals within 48 hours.

Write your message here and send it to us