Products

12V Drum Lifting Winch Motor Drum Motor Electric Winch Lifting And Lowerin

Products Description

Profile

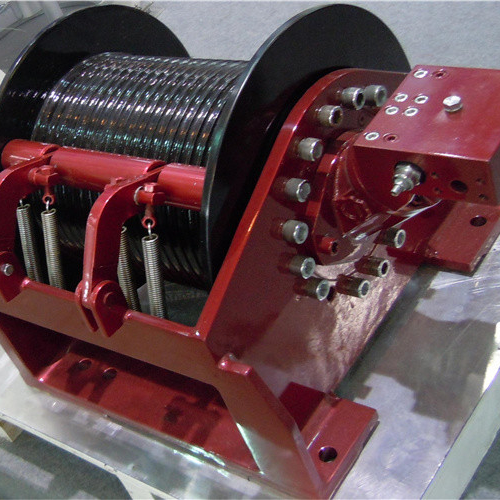

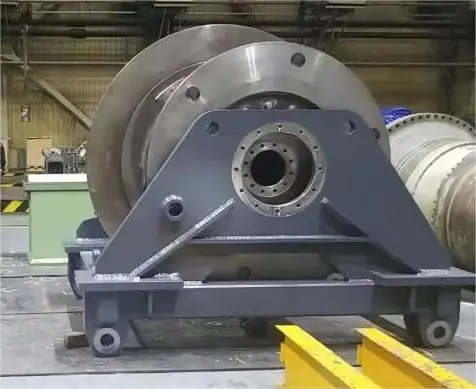

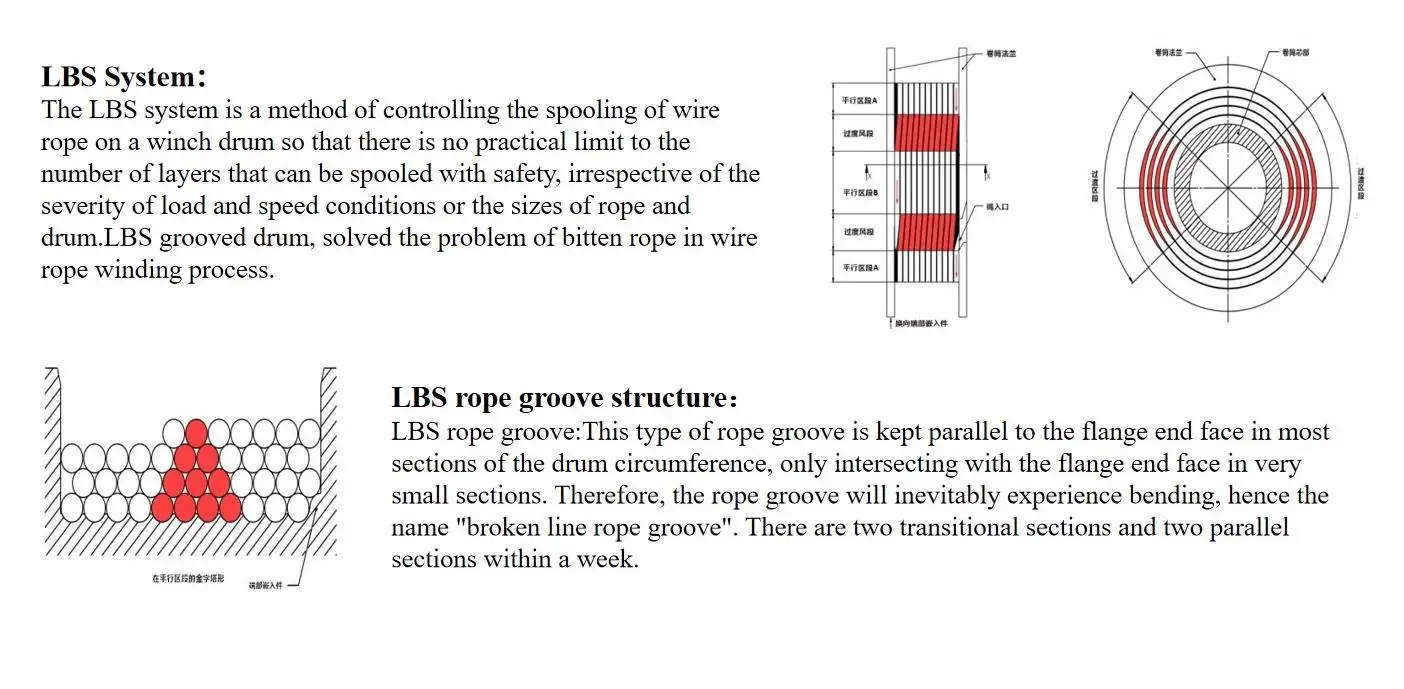

The term “double fold line wire rope groove” currently popular in the lifting industry in China refers to a type of steel wire rope suitable for multi-layer production introduced from abroad winding rope groove form. Due to the fact that this type of rope groove remains parallel to the flange end face in most sections of the drum circumference, only in a very small area the section intersects with the flange end face, so the rope groove will inevitably experience bending, hence the name “double fold line rope groove” and make it for a specialized rope winding technique.

A typical lebus built drum is composed of a welded plain drum and a welded grooved shell. In the event of a malfunction, simply replacing the sleeves can greatly save costs and reduce expenses.

Advantages

In recent years, our products have been widely used in the fields of offshore platform cranes, oil workover drilling winches, logging rope winding equipment, wall wiping machine winches, helicopter motor winches, and so on. With its high reputation, high-quality products and service system, it has received widespread praise from domestic and foreign customers.

Technical Parameters

|

Product Basic Parameters(Specific specifications can be customized according to requirements):

|

|||

|

Product Name

|

LBS Winch Drum

|

Type Specification

|

LBSWD-202310004

|

|

Byname

|

Winch Accessory

|

Processing Customization

|

Yes

|

|

Brand

|

LBS

|

Producing Area

|

Shijiazhuang, Hebei, China

|

|

Production Facility

|

CNC Center

|

Certification

|

ISO9001

|

|

Function

|

Lifting heavy objects, pulling objects, adjusting weight, providing strength

|

Application

|

Hoisting equipment such as winches

|

|

Color

|

Customized

|

MOQ

|

1 pcs

|

|

Material

|

Alloy steel

|

Processing Method

|

Machining operation

|

|

Rope Groove Type

|

Lebus or spiral

|

Rope Capacity

|

10-10000m

|

|

Rope Type

|

3-200mm

|

Power Source

|

Electric motor

|

|

Applicable Object

|

Winch

|

Accessory Products

|

Lifting structure

|

|

Overall Structure

|

Flange, simplified body, pressure plate, rib plate, gear ring, etc

|

Weight

|

1000kg

|

|

Ambient Temperature

|

-40℃-+45℃

|

Storage Temperature

|

-40℃-+50℃

|

|

Specific specifications can be discussed. Welcome to the news consulation!

|

|||

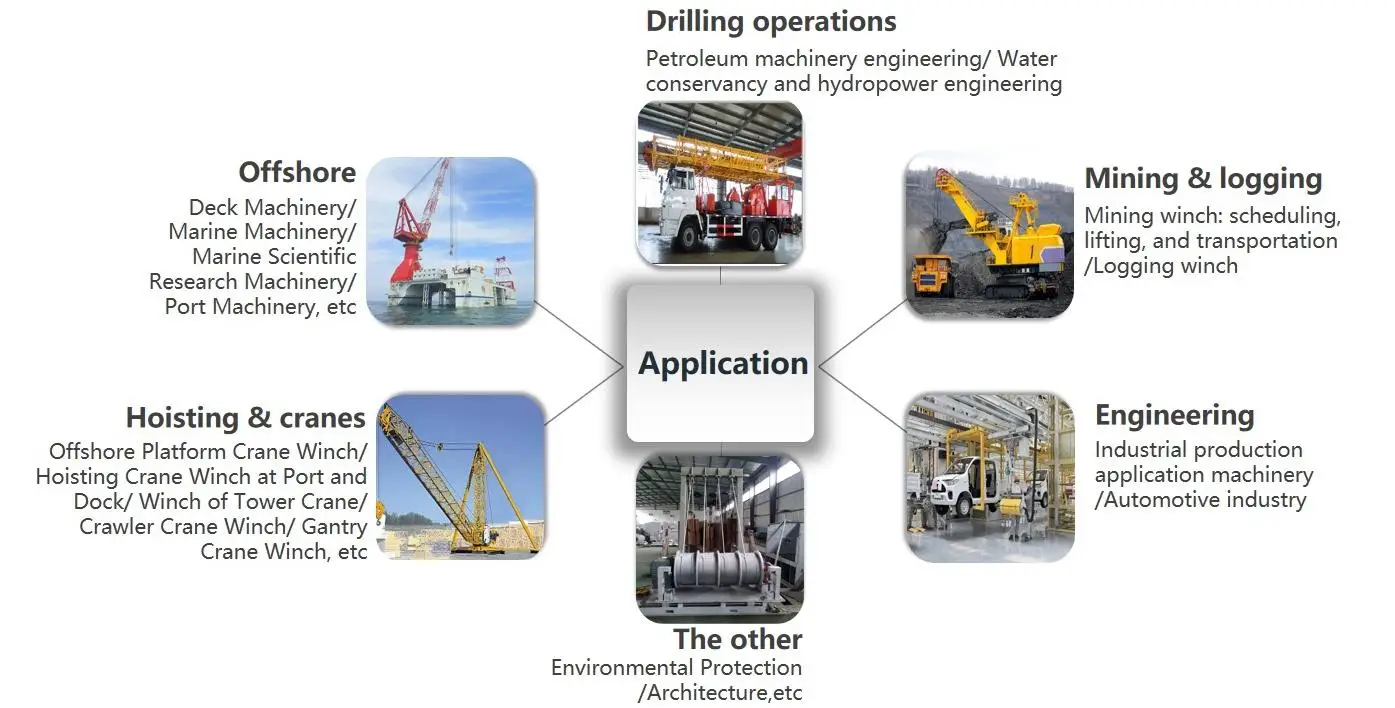

Application

The LBS series Grooved Winch Drum is widely used in a variety of construction and engineering projects. These include water conservancy projects, forestry, mines, wharves, and more. It can be used effectively for material lifting or flat dragging. Additionally, it can be used as a auxiliary equipment for certain kinds of modern automated operations.

The LBS series Grooved Winch Drum is driven by a gear reducer, which provides an efficient and reliable means of powering material hoists. As such, it is suitable for many different applications, such as civil construction and the installation of projects from construction and mining companies, and even factories.

Support and Services

Products Technical Support and Service

We understand how important it is for our customers to have reliable technical support and service for their products. We are here to provide the best possible assistance when it comes to any questions or issues you may have. Our experienced team of experts is available to help you find the best solution for your needs. We offer a variety of technical support options, ranging from troubleshooting and installation to product advice and maintenance. Our technical support team is available 24 hours a day, 7 days a week to answer any questions you may have. In addition to our technical support services, we also provide a wide range of services to keep your products running efficiently and effectively. These services include regular maintenance, repair, and replacement. We can also provide assistance with customization and upgrades if necessary. We strive to provide the best possible technical support and service for our customers. We are committed to keeping your products running smoothly and efficiently. If you have any questions or issues, please do not hesitate to contact us. Our team of experts is here to help.

Processing Technic

Packing and Shipping

1.Each product is packed in a strong wooden boxes or pallets. 2.The box is labelled with the product details, such as the model number, and other relevant information. 3.We use reliable shipping providers to ensure that our Grooved Drum Sleeves reach their destination safely and on time.

Successful project

Write your message here and send it to us