Pro Designed Alloy Steel LBS Rope Groove Drums - Durable & Reliable

Introduction to Advanced Winch Drum Technology

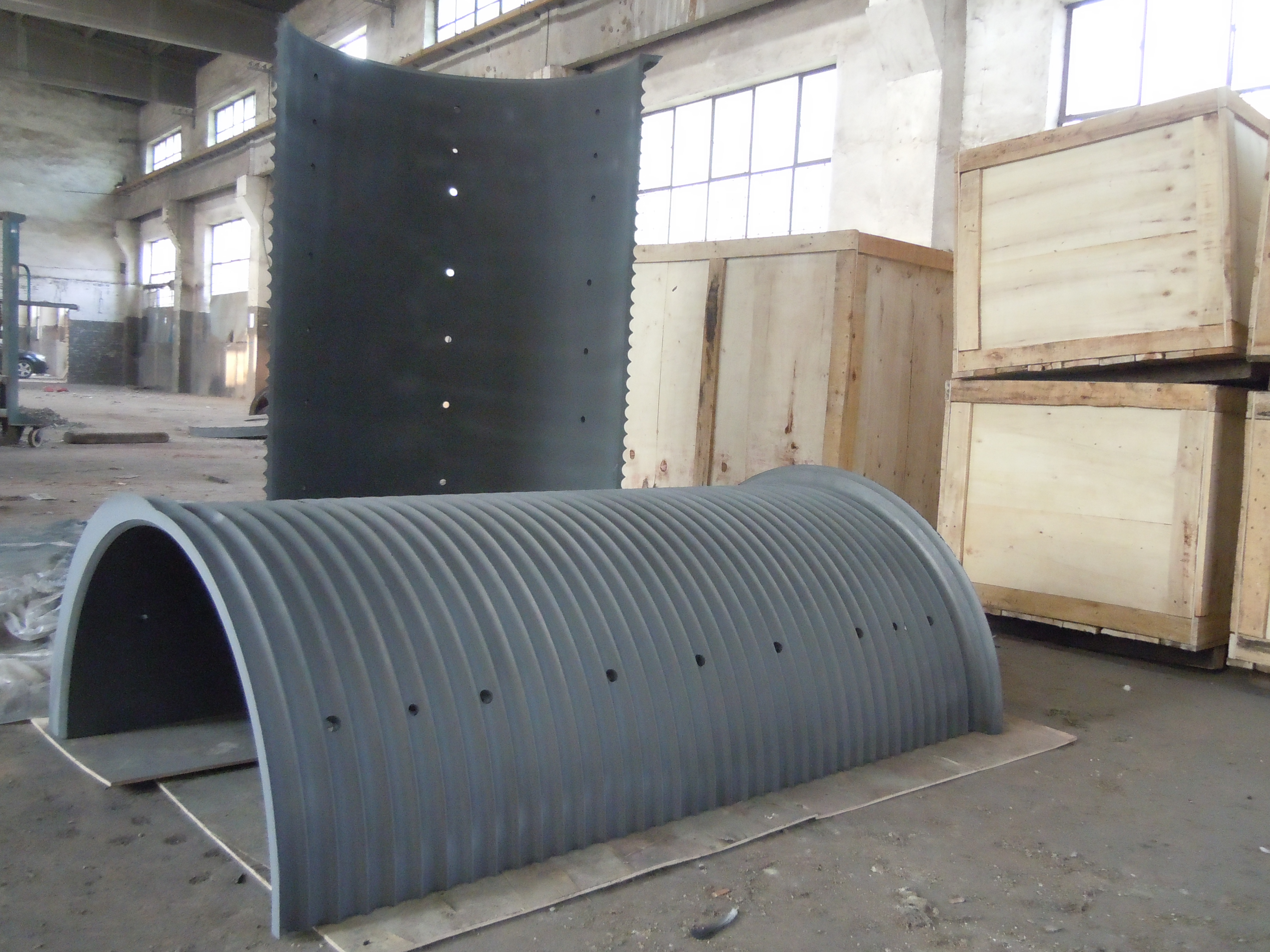

In high-stakes industrial applications, the reliability and longevity of winch components are paramount. The efficiency of a lifting or pulling operation hinges significantly on the performance of the rope drum. Traditional winch drums, while functional, often lead to premature rope wear, uneven spooling, and increased maintenance demands. Addressing these critical challenges, the industry has evolved towards highly engineered solutions. This article delves into the intricacies of Professional Design And Manufacturing Durable Alloy Steel LBS Rope Groove Drum Leather, a cutting-edge component engineered to redefine operational efficiency and safety across demanding sectors.

These specialized drums integrate advanced material science with precision engineering, ensuring optimal rope management, reduced operational costs, and extended service intervals. They represent a significant leap forward from conventional designs, providing solutions for complex lifting, hoisting, and pulling mechanisms where precision and durability are non-negotiable. Our focus will explore the comprehensive manufacturing process, technical advantages, diverse application scenarios, and the stringent quality standards that underpin the superiority of these advanced components.

Industry Trends in Winch Drum Technology

The industrial winch sector is currently experiencing a transformative phase, driven by several key trends aimed at enhancing performance, safety, and operational longevity. There's a noticeable shift towards higher strength-to-weight ratio materials, such as specialized alloy steels, to meet the demands of increased load capacities without compromising structural integrity. Precision manufacturing techniques, including advanced CNC machining and robotic welding, are becoming standard to achieve tighter tolerances and superior surface finishes for optimal rope handling.

Furthermore, the integration of smart technologies like IoT sensors for real-time monitoring of rope tension, drum speed, and temperature is gaining traction. This allows for predictive maintenance, preventing catastrophic failures and minimizing downtime. There's also a strong emphasis on environmentally sustainable manufacturing processes and materials that offer extended service life, thereby reducing waste and resource consumption. The demand for highly durable, corrosion-resistant drums capable of operating in extreme environments – from offshore platforms to corrosive chemical plants – is propelling innovations in surface treatments and material selection. These trends collectively underscore the critical need for components like the Professional Design And Manufacturing Durable Alloy Steel LBS Rope Groove Drum Leather, which embody these advancements.

Manufacturing Process Flow: Engineering Excellence

The production of a Professional Design And Manufacturing Durable Alloy Steel LBS Rope Groove Drum Leather is a meticulously controlled, multi-stage process that combines advanced metallurgical science with precision engineering. Each step is critical to ensure the drum meets the stringent performance and durability requirements of industrial applications.

1. Design and Engineering Phase:

This initial phase utilizes Computer-Aided Design (CAD) for detailed drum geometry and Finite Element Analysis (FEA) to simulate stress distribution under various load conditions. The LBS (Lebus) groove profile, a hallmark of these drums, is precisely engineered at this stage to ensure optimal rope spooling and minimize fleet angle issues. This proactive design mitigates potential points of failure, enhancing overall structural integrity.

2. Material Selection and Preparation:

High-grade alloy steels, such as 42CrMo4, 34CrNiMo6, or equivalent ASTM/AISI standards, are selected for their superior tensile strength, yield strength, and fatigue resistance. These materials are chosen to withstand extreme operational stresses, including high radial and axial loads. The raw material undergoes rigorous inspection to confirm its chemical composition and mechanical properties, aligning with international standards like ISO 683, EN 10083, and ASTM A29.

3. Forging or Casting:

Depending on the drum's size and specific application requirements, the initial form is created either through forging or casting.

- Forging: This process involves shaping the alloy steel under immense pressure and heat, refining the grain structure, and eliminating internal defects. This results in superior mechanical properties, including increased toughness and ductility, making it ideal for drums under dynamic loads.

- Casting: For larger or complex geometries, precision casting is employed. Advanced casting techniques minimize porosity and ensure uniform material distribution. Subsequent processing is crucial to achieve the required strength and structural integrity.

4. Heat Treatment:

Post-forging or casting, the drum undergoes a meticulously controlled heat treatment regimen. This typically includes normalizing, quenching, and tempering. Normalizing refines the grain structure, quenching increases hardness, and tempering reduces brittleness while achieving the desired balance of strength and toughness. Stress relief annealing is often performed to mitigate residual stresses from manufacturing, preventing warping and improving fatigue life.

5. CNC Machining and LBS Grooving:

The rough form is then subjected to highly precise CNC (Computer Numerical Control) machining. This stage creates the exact dimensional specifications, shaft bores, and, critically, the LBS (Lebus) rope grooves. The LBS system ensures that the rope spools in an organized, even manner, layer by layer, eliminating crossover points and significantly extending rope service life. Surface finish parameters are tightly controlled to minimize friction and wear on the wire rope.

6. Surface Treatment (Optional but Recommended):

For drums operating in corrosive environments (e.g., marine, chemical processing, petrochemical), specialized surface treatments such as nitriding, phosphating, or application of corrosion-resistant coatings may be applied. These treatments enhance wear resistance and provide a protective barrier against environmental degradation, contributing to the drum's exceptional service life and corrosion resistance.

7. Quality Control and Testing:

Throughout the manufacturing process, stringent quality control measures are implemented. This includes:

- Non-Destructive Testing (NDT): Ultrasonic testing (UT), magnetic particle inspection (MPI), and dye penetrant inspection (DPI) are used to detect internal and surface flaws.

- Dimensional Verification: Precision instruments ensure all dimensions, including groove profile, diameter, and length, adhere to design specifications and industry standards like ANSI/ASME B30.5 or relevant API standards.

- Material Property Testing: Hardness testing (e.g., Brinell, Rockwell), tensile strength, and impact testing (e.g., Charpy V-notch) confirm mechanical properties.

- Load Testing (Simulated): Where applicable, load testing simulates operational conditions to validate structural integrity and performance.

Adherence to international testing standards such as ISO 9001 for quality management, ISO 14001 for environmental management, and specific product standards (e.g., API 2C for offshore cranes) ensures consistency and reliability. The typical service life of such a professionally manufactured drum can range from 15 to 30 years, depending on application severity and maintenance practices.

Technical Specifications and Parameters

Understanding the precise technical parameters of a Professional Design And Manufacturing Durable Alloy Steel LBS Rope Groove Drum Leather is crucial for system integration and performance optimization. These drums are not off-the-shelf components but engineered solutions with specific characteristics tailored for demanding operations.

The implementation of the LBS grooving system is a critical technical advantage. Unlike helical grooves, LBS grooves ensure the wire rope lays in parallel wraps, eliminating the fleet angle problem common with conventional drums. This prevents crushing and fraying, distributing wear evenly across the rope and the drum surface. The result is a substantial extension of wire rope service life, often by 200-500%, significantly reducing operational costs and safety risks associated with rope failure.

Application Scenarios and Industry Benefits

The robust design and superior performance characteristics of alloy steel LBS rope groove drums make them indispensable in a variety of challenging industrial environments where safety, reliability, and efficiency are paramount.

Target Industries:

- Petrochemical Industry: Essential for drilling rigs (onshore and offshore), pipe-laying vessels, and process plant lifting equipment. The corrosion resistance and high load capacity are critical for operations in harsh, often explosive, environments. Energy saving is achieved through smoother operations and reduced friction, lowering power consumption for hoisting.

- Metallurgy and Steel Mills: Used in heavy-duty cranes for ladle handling, coil transport, and furnace maintenance. The extreme temperatures and abrasive dust demand components with exceptional durability and thermal stability. The extended service life of wire ropes translates directly to reduced downtime during critical production cycles.

- Water Supply & Drainage (Hydropower & Dams): Integral to dam gate hoists, sluice gate operations, and pump station mechanisms. These applications often involve long service intervals in wet, sometimes corrosive, conditions. The corrosion resistance of alloy steel ensures reliable long-term performance, and the precise spooling prevents rope damage from cyclical operations.

- Marine and Offshore Operations: Employed in ship cranes, anchor winches, mooring systems, and subsea lifting equipment. These drums withstand saltwater corrosion, dynamic loads, and continuous operation in demanding maritime conditions. Reduced rope wear is vital for safety and cost-efficiency in remote offshore environments.

- Mining and Heavy Construction: Critical for hoists in underground mines, heavy-duty mobile cranes, and material handling systems. The ability to handle significant loads and resist impact wear is paramount for operational safety and continuous output.

In typical application scenarios, such as a large gantry crane in a shipyard, the adoption of a Professional Design And Manufacturing Durable Alloy Steel LBS Rope Groove Drum Leather can lead to significant energy savings through optimized rope layering, which reduces friction and strain on the motor. Furthermore, in chemical processing plants, the inherent corrosion resistance of the chosen alloy steel, often supplemented with specialized coatings, ensures operational integrity in the presence of aggressive chemicals, preventing premature component failure and ensuring safety compliance.

Technical Advantages and Performance Superiority

The advanced engineering and material science behind alloy steel LBS rope groove drums confer a suite of technical advantages that translate directly into operational benefits and cost savings for industrial enterprises.

- Optimized Rope Spooling (LBS System): The Lebus grooving system eliminates the chaotic winding and crushing characteristic of traditional helical drums. By guiding each rope wrap precisely into parallel layers, it ensures smooth, even spooling. This controlled winding minimizes internal rope friction and crushing, preventing premature failure modes.

- Extended Wire Rope Service Life: This is arguably the most significant advantage. By preventing crossover points, pinching, and abrasion, the LBS system dramatically reduces wear on the wire rope. Studies and field data often show a 200% to 500% increase in rope service life, directly leading to lower consumables cost and reduced replacement frequency.

- Superior Durability (Alloy Steel): The use of heat-treated alloy steel provides exceptional strength, toughness, and fatigue resistance compared to standard carbon steels or cast iron. This material choice ensures the drum itself withstands high operational stresses, impact loads, and cyclic fatigue over decades of service, reducing the need for drum replacement.

- High Load Bearing Capacity: Engineered with precision and robust materials, these drums are capable of handling significantly higher working load limits (WLL) than conventional drums. This is critical for heavy-lift applications, providing a greater margin of safety and operational flexibility.

- Reduced Maintenance Requirements: The combination of extended rope life and inherent drum durability means less frequent inspection and replacement of both the rope and the drum. This significantly reduces maintenance labor, spare parts inventory, and associated operational downtime.

- Enhanced Safety: Consistent and organized rope spooling minimizes the risk of sudden rope failures, snags, or uncontrolled unwinding, contributing to a safer working environment for operators and surrounding personnel. The structural integrity of the alloy steel further reinforces operational safety.

- Corrosion and Abrasion Resistance: Depending on the alloy and potential surface treatments (e.g., nitriding, specialized coatings), these drums offer excellent resistance to corrosive agents (like saltwater, chemicals) and abrasive particles. This extends the drum's life in harsh environmental conditions.

Vendor Comparison: Why Choose Specialized Drums

When sourcing winch drums, industrial decision-makers face a choice between conventional, mass-produced drums and specialized, engineered solutions like the Professional Design And Manufacturing Durable Alloy Steel LBS Rope Groove Drum Leather. A detailed comparison highlights the significant long-term value offered by the latter.

While the initial investment for a specialized LBS alloy steel drum might be higher, the total cost of ownership (TCO) is demonstrably lower over the operational lifespan. The extended wire rope life, reduced maintenance needs, and minimized downtime translate into substantial savings, proving that superior engineering delivers economic advantages in the long run.

Customized Solutions and Design Flexibility

Recognizing that no two industrial applications are exactly alike, leading manufacturers of Professional Design And Manufacturing Durable Alloy Steel LBS Rope Groove Drum Leather offer comprehensive customization services. This ensures that each drum is perfectly tailored to the specific operational demands, integration requirements, and environmental conditions of the client's system.

Key Customization Areas:

- Dimensions and Capacity: Drums can be manufactured to precise diameters, lengths, and rope capacities to match existing winch systems or new project specifications. This includes multi-layer grooving for applications requiring significant rope storage.

- Material Selection and Metallurgy: Beyond standard alloy steels, specific material grades can be chosen for extreme temperature resistance, enhanced corrosion protection (e.g., for acid environments), or superior impact toughness. This involves tailoring the chemical composition and heat treatment processes.

- Surface Treatments and Coatings: Specialized coatings such as hard chrome plating, nitriding, or polymer-based coatings can be applied to further enhance wear resistance, corrosion protection, or reduce friction, optimizing performance in particular harsh conditions.

- Integrated Components and Features: Customization extends to integrating components like shaft designs, bearing journals, gear flanges, brake drums, or even internal chambers for heating/cooling elements. Sensor integration for load monitoring, temperature, or rope tension can also be incorporated.

- Compliance with Specific Standards: Drums can be designed and manufactured to comply with specific industry certifications (e.g., DNV GL, ABS, Lloyd's Register for marine, API for oil & gas) or regional regulatory requirements, ensuring global applicability.

This bespoke approach ensures that clients receive a drum that is not just a component, but an optimized solution for their unique operational challenges, maximizing system performance and longevity.

Application Case Studies: Real-World Impact

The tangible benefits of a Professional Design And Manufacturing Durable Alloy Steel LBS Rope Groove Drum Leather are best illustrated through real-world applications where they have demonstrably improved performance, reduced costs, and enhanced safety.

Case Study 1: Offshore Drilling Platform Crane

- Challenge: A leading offshore drilling company faced recurring issues with premature wire rope failure on their main drilling rig crane, operating in highly corrosive saltwater environments and under continuous, heavy cyclic loads. Rope replacement was required every 6-8 months, leading to significant downtime costs (estimated at $250,000 per day) and safety concerns.

- Solution: The existing conventional helical grooved drum was replaced with a custom-engineered LBS alloy steel drum, incorporating a specialized anti-corrosion coating. The drum was designed to precisely match the rig's operational parameters and rope specifications.

- Results: After implementation, the wire rope service life extended to over 24 months, representing a 300% improvement. This translated to a reduction in rope replacement frequency by two-thirds, saving millions in downtime and maintenance costs annually. Safety incident reports related to rope failure drastically declined, improving overall operational integrity.

Case Study 2: Steel Mill Ladle Crane Hoist

- Challenge: A large steel manufacturing plant experienced frequent wear on their overhead ladle crane hoist ropes due to heavy loads, high temperatures, and abrasive dust present in the casting area. The conventional drums allowed for inconsistent rope layering, leading to concentrated wear points and necessitating quarterly rope changes.

- Solution: An LBS alloy steel drum, forged from 34CrNiMo6 steel for enhanced toughness and heat resistance, was installed. The precision LBS grooving ensured perfectly uniform rope spooling, distributing stress evenly along the rope.

- Results: Wire rope life increased from 3 months to 15 months, a 400% improvement. This drastically reduced the frequency of risky and time-consuming rope changes in a challenging environment. The enhanced drum durability also meant no signs of drum wear after several years of operation, further reducing long-term maintenance costs and improving overall safety and efficiency in critical hot metal transport operations.

Trustworthiness & Company Commitments

Our commitment to delivering excellence in Professional Design And Manufacturing Durable Alloy Steel LBS Rope Groove Drum Leather is underpinned by stringent quality protocols, robust support systems, and a dedication to client satisfaction.

Certifications and Compliance:

Our manufacturing facilities adhere to ISO 9001:2015 Quality Management Systems, ensuring consistent quality across all production stages. Products are designed and produced in compliance with international standards such as API Specification Q1, DNV GL, ABS, Lloyd's Register, and client-specific requirements. Material traceability and comprehensive testing data are provided with every drum, offering full transparency and assurance of quality. We partner with leading industry players globally, a testament to our consistent delivery of high-performance solutions over decades of service.

Lead Time and Fulfillment:

Typical lead times for custom LBS alloy steel drums range from 8 to 16 weeks, depending on complexity, size, and material availability. Standard configurations may have shorter lead times. We maintain efficient production schedules and provide clear communication on progress, ensuring timely delivery to minimize project delays. Expedited manufacturing options are available for critical requirements.

Warranty Commitments:

We stand by the quality and durability of our products with a comprehensive warranty against manufacturing defects and material failures under normal operating conditions. Our standard warranty period is 24 months from the date of delivery or 18 months from installation, whichever comes first. Specific project warranties can be negotiated based on application severity and operational profile.

Customer Support and After-Sales Service:

Our dedicated customer support team provides comprehensive technical assistance, installation guidance, and troubleshooting services. We offer global support through our network of service partners, ensuring rapid response and minimal operational disruption. From initial consultation and design to post-installation support and periodic inspections, we partner with our clients throughout the entire lifecycle of our products, guaranteeing optimal performance and longevity.

Frequently Asked Questions (FAQ)

- Q: What is an LBS rope groove drum?

- A: An LBS (Lebus) rope groove drum features a precision-machined, dual-helix grooving system that ensures the wire rope spools in perfectly parallel layers. This eliminates cross-winding, pinching, and uneven wear, significantly extending the life of the wire rope and enhancing operational safety.

- Q: Why choose alloy steel for winch drums?

- A: Alloy steel offers superior mechanical properties compared to standard carbon steel or cast iron, including higher tensile strength, yield strength, fatigue resistance, and toughness. When heat-treated, it provides exceptional durability, allowing the drum to withstand heavy loads, harsh environments, and cyclic operations for decades.

- Q: How much does an LBS drum extend wire rope life?

- A: Field data and studies consistently show that LBS grooved drums can extend wire rope service life by 200% to 500% compared to conventional drums. This results in substantial cost savings from reduced rope replacement and minimized operational downtime.

- Q: Can these drums be customized for specific applications?

- A: Absolutely. Our manufacturing process is highly adaptable. We offer extensive customization options for dimensions, material grades, surface treatments, integration with other components (e.g., shafts, gear flanges), and compliance with specific industry or regulatory standards.

- Q: What kind of maintenance is required for an LBS alloy steel drum?

- A: Due to their robust construction and optimized rope management, LBS alloy steel drums require minimal maintenance beyond regular inspections. The primary focus shifts to routine wire rope inspection and lubrication, rather than frequent drum repairs or replacements, due to the reduced wear profile.

Conclusion

The continuous evolution of industrial operations demands components that offer unparalleled performance, durability, and safety. The Professional Design And Manufacturing Durable Alloy Steel LBS Rope Groove Drum Leather stands as a testament to this demand, embodying the pinnacle of winch drum technology. By meticulously controlling every aspect of design and manufacturing, from advanced material selection and precision machining to rigorous quality control, these drums provide a critical advantage in enhancing efficiency and reliability across the petrochemical, metallurgy, marine, and heavy construction industries. The long-term cost savings derived from extended wire rope life, reduced maintenance, and superior operational safety far outweigh the initial investment, making these specialized drums an intelligent choice for any demanding application.

References

- ISO 9001:2015 - Quality management systems - Requirements. International Organization for Standardization.

- API Specification 2C - Offshore Cranes. American Petroleum Institute.

- Lebus International Engineers Ltd. - Lebus Grooving Systems Technical Manual.

- DNV GL Classification Society Rules for Ships, Offshore Units and Structures.

- ASTM A29/A29M - 20 Standard Specification for General Requirements for Steel Bars, Carbon and Alloy, Hot-Wrought, Metric.

- EN 10083-1:2006 Steels for quenching and tempering - Part 1: General technical delivery conditions.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025