Premium Drum Anchor Winch For Sale - Durable & High-Performance

Introduction to High-Performance Drum Anchor Winches

In demanding industrial and marine applications, the reliability and performance of hoisting and pulling equipment are paramount. A crucial component in these systems is the robust drum anchor winch for sale, designed for secure and efficient handling of heavy loads, particularly in anchoring operations. These specialized winches, often featuring multi-layer winding capabilities and precision rope groove drums, are engineered to deliver unparalleled stability and operational safety in the most challenging environments. From offshore oil rigs to large-scale construction sites and maritime vessels, the integrity of these systems directly impacts operational continuity and personnel safety.

This article delves into the intricate details of modern drum anchor winches, exploring their core engineering, manufacturing excellence, diverse applications, and the strategic advantages they offer to B2B stakeholders. We will provide a comprehensive overview, covering everything from material science and production methodologies to performance metrics and customization options, ensuring a thorough understanding for decision-makers and technical professionals.

Industry Trends and Market Dynamics

The market for heavy-duty winches, including specialized drum and drum anchor winch for sale units, is experiencing significant growth, driven by escalating demands in sectors such as offshore energy, maritime logistics, and large-scale infrastructure development. Key trends indicate a strong push towards enhanced automation, increased load capacities, and superior durability. The adoption of advanced materials and manufacturing techniques is pivotal in meeting these evolving requirements. For instance, the global marine winch market size was valued at approximately USD 1.5 billion in 2022 and is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.5% from 2023 to 2030, underscoring the robust demand for reliable hoisting and mooring solutions.

Furthermore, there is a rising emphasis on energy efficiency and environmental compliance. Manufacturers are integrating variable frequency drives (VFDs) and regenerative braking systems to reduce power consumption and operational costs. The demand for customized solutions, particularly for specialized marine and industrial projects, is also shaping market dynamics, with clients increasingly seeking winches designed to precise operational envelopes. The need for a robust drum winch for sale that can withstand corrosive marine environments or extreme industrial conditions is driving innovation in protective coatings and material selection.

The shift towards remote monitoring and predictive maintenance, facilitated by IoT integration, is another transformative trend. This allows operators to monitor winch performance in real-time, predict potential failures, and schedule maintenance proactively, thereby minimizing downtime and extending service life. Such technological advancements are crucial for ensuring the continuous and safe operation of critical equipment.

Technical Specifications and Engineering Parameters

The core of any high-performance drum anchor winch for sale lies in its technical specifications. Our steel wire rope multi-layer winding winch crane used Q355/S355JR/A709Gr50 LBS rope groove drums are engineered for optimal performance and longevity. The selection of materials like Q355, S355JR, and A709Gr50 is critical, offering superior yield strength, tensile strength, and impact resistance essential for handling extreme loads and stresses. For instance, Q355 structural steel provides a minimum yield strength of 355 MPa, making it ideal for heavy-duty applications.

Key technical parameters include drum diameter, length, rope capacity, design factor, and material properties. The precision of the rope groove design (e.g., Lebus or helical) is vital for ensuring multi-layer winding integrity, preventing rope crushing and extending wire rope service life. Below is a detailed table showcasing typical product specifications:

| Parameter | Specification | Details/Benefit |

|---|---|---|

| Material Grade | Q355, S355JR, A709Gr50 | High yield strength (min 355 MPa), excellent toughness and weldability for structural integrity. |

| Drum Diameter Range | 200 mm - 4000 mm (customizable) | Accommodates various wire rope diameters and capacities for diverse applications. |

| Rope Capacity | Up to 5000 meters of wire rope | Suitable for deep-sea anchoring, extensive lifting, and long-distance pulling. |

| Rope Groove Type | Lebus or Helical Grooved | Ensures precise multi-layer winding, prevents rope crossover, minimizes wear, extends rope life by 2x-3x. |

| Working Load Limit (WLL) | 5 Tons - 500 Tons (dependent on design) | Engineered for heavy-duty lifting and pulling, ensuring safety factors compliant with international standards. |

| Surface Treatment | Anti-corrosion coating, Sandblasting SA2.5 | Enhanced resistance to harsh environmental conditions, especially marine and chemical exposures. |

| Design Standards | ISO 9001, AWS D1.1, DNV-GL, ABS, Lloyd's Register | Adherence to international quality and safety benchmarks, ensuring product reliability and compliance. |

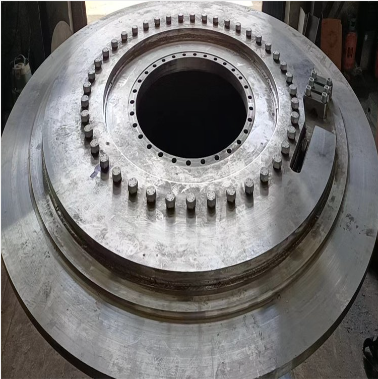

Manufacturing Process Flow for Precision Drums

The production of a high-quality drum anchor winch for sale drum is a meticulous process demanding precision engineering and stringent quality control. Our manufacturing process ensures that each drum meets the highest industry standards for durability and performance.

-

1. Material Selection & Preparation:

We begin with certified steel plates or forgings of Q355, S355JR, or A709Gr50, chosen for their superior strength and fatigue resistance. Material certificates (MTCs) are verified to ensure compliance with international standards like ASTM and EN. Plates are precisely cut using CNC plasma or laser cutting technologies.

-

2. Forming and Welding:

The cut steel plates are then rolled into cylindrical shapes using advanced plate bending machines. Skilled welders, certified to AWS D1.1 or ISO 9606, meticulously join the drum sections using submerged arc welding (SAW) or gas metal arc welding (GMAW). Each weld undergoes non-destructive testing (NDT) such as ultrasonic testing (UT) or magnetic particle inspection (MPI) to detect any internal flaws, ensuring structural integrity.

-

3. CNC Machining of Rope Grooves:

This is a critical stage. The formed drum is mounted on large-scale CNC lathes where precision rope grooves (Lebus or helical) are machined. The accuracy of these grooves, typically to tolerances of ±0.05 mm, is paramount for multi-layer winding, preventing rope entanglement and maximizing rope life. This process ensures the drum's long service life, often exceeding 20 years with proper maintenance, significantly reducing operational expenditure.

-

4. Heat Treatment (Stress Relief):

After extensive welding and machining, the drum undergoes stress relief heat treatment in a controlled furnace. This process removes residual stresses induced during fabrication, enhancing the material's ductility and preventing potential distortion or cracking in service, especially in high-stress, cyclical loading applications.

-

5. Surface Preparation and Coating:

The drum surface is thoroughly cleaned and prepared, often via sandblasting to SA2.5 standard, to ensure optimal adhesion for protective coatings. Multiple layers of marine-grade anti-corrosion paint or specialized epoxy coatings are applied, providing exceptional resistance to harsh environments, saltwater, and industrial chemicals. This extends the drum's lifespan and reduces maintenance frequency.

-

6. Final Inspection and Testing:

Each drum undergoes a comprehensive final inspection, including dimensional checks, surface finish assessment, and sometimes a dynamic balancing test. Material traceability, welding procedures, and NDT reports are compiled for full documentation. All products are tested to meet or exceed international standards such as ISO, ANSI, and specific class society rules (e.g., DNV-GL, ABS, Lloyd's Register).

This rigorous process ensures that the finished drum is not only structurally sound but also optimized for energy saving through reduced friction and wear, highly corrosion-resistant, and delivers reliable performance throughout its extended service life, which is critical for target industries like petrochemical, metallurgy, and water supply & drainage.

Application Scenarios for Drum Anchor Winches

The versatility and robustness of modern drum anchor winch for sale systems make them indispensable across a broad spectrum of industrial and marine applications. Their ability to handle high tensile loads and long wire ropes with precision is crucial for safe and efficient operations.

- Offshore Oil & Gas Industry: Used extensively for mooring drilling rigs, floating production storage and offloading (FPSO) vessels, and subsea installation operations. The precise control offered by these winches is vital for maintaining station keeping in dynamic marine environments.

- Maritime and Shipping: Essential for anchoring large commercial vessels, tugboats, and offshore supply vessels. They facilitate secure berthing, towing operations, and the deployment of specialized equipment. Many applications also demand a reliable double drum winch for sale for multi-purpose operations.

- Construction and Civil Engineering: Employed in large-scale infrastructure projects such as bridge construction, dam building, and heavy machinery installation. They are used for hoisting massive structural components, pulling heavy equipment, and tensioning cables.

- Mining and Metallurgy: Critical for ore hoisting in deep mines, pulling heavy wagons, and positioning massive equipment in processing plants. The durability of the drums in abrasive environments is a key advantage.

- Water Supply & Drainage / Hydropower: Used for operating sluice gates, managing penstocks, and maintaining large-scale water control structures. The corrosion resistance of the drums ensures long-term functionality in wet and humid conditions.

- Cranes and Hoisting Equipment: Form the core lifting mechanism for overhead cranes, gantry cranes, and mobile cranes in various industrial settings, enabling precision lifting and positioning of heavy loads.

In these scenarios, the ability of the multi-layer winding drum to extend wire rope life and ensure consistent performance under cyclical loading conditions translates directly into reduced operational costs and enhanced safety records.

Technical Advantages and Performance Enhancements

Investing in a high-quality drum anchor winch for sale offers numerous technical advantages that translate into significant operational benefits. These advantages are rooted in superior design, material science, and manufacturing precision.

- Extended Wire Rope Service Life: Precision-machined Lebus or helical grooves ensure perfect multi-layer winding, eliminating wire rope crushing, bird-caging, and uneven wear. This extends the rope's lifespan by 2 to 3 times compared to smooth drums, drastically reducing replacement costs and downtime.

- Enhanced Safety and Reliability: Consistent rope spooling reduces the risk of operational failures, snags, and accidental drops. The robust construction from certified materials (Q355, S355JR) ensures high safety factors, minimizing the likelihood of catastrophic equipment failure.

- Superior Corrosion Resistance: Specialized surface treatments and marine-grade coatings provide exceptional protection against saltwater, chemicals, and abrasive particles. This makes them ideal for offshore, port, and harsh industrial environments, ensuring a long operational life without degradation.

- Energy Efficiency: Optimized drum geometry and smooth rope winding minimize friction and wear, leading to lower power consumption during hoisting and lowering operations. When integrated with VFDs, overall energy savings can reach 20-30%, contributing to lower operating expenses and a reduced carbon footprint.

- High Load Capacity and Durability: Engineered to withstand extreme static and dynamic loads, these drums maintain structural integrity under continuous, heavy-duty operation. The choice of high-strength alloy steels ensures resistance to fatigue, impact, and abrasion, offering unparalleled durability.

- Reduced Maintenance Requirements: The combination of extended rope life, corrosion resistance, and robust construction means less frequent maintenance, reduced need for component replacements, and consequently, lower total cost of ownership (TCO).

Vendor Comparison and Selection Criteria

When sourcing a drum anchor winch for sale, selecting the right vendor is as critical as the product itself. The market offers various options, from standard industrial drum winch for sale units to highly specialized double drum winch for sale configurations. A comprehensive evaluation based on key criteria ensures optimal investment and long-term performance.

| Criterion | Leading Manufacturer (e.g., LBS Winch) | Generic Supplier |

|---|---|---|

| Material Quality & Traceability | Certified Q355/S355JR/A709Gr50 steel, full MTC documentation. | Often unverified or lower-grade steel, limited documentation. |

| Manufacturing Precision | Advanced CNC machining for rope grooves, tight tolerances (±0.05 mm). | Manual or less precise machining, resulting in irregular grooves. |

| Welding & NDT Standards | AWS/ISO certified welders, 100% NDT (UT/MPI/RT). | Basic welding, minimal or no NDT, higher risk of weld defects. |

| Surface Treatment & Corrosion | Multi-layer marine-grade coating, SA2.5 sandblasting, 5+ years corrosion warranty. | Standard paint, poor surface prep, short-term corrosion resistance. |

| Design & Engineering Capability | In-house engineering, customized solutions, FEA analysis, class society certifications (DNV-GL, ABS). | Off-the-shelf designs, limited customization, basic compliance. |

| Certifications & Quality Management | ISO 9001, API Spec Q1, specific product certifications (CE, Lloyd's). | Basic manufacturing certifications, sometimes unverified. |

| Service Life Expectancy | 20+ years with proper maintenance, significantly extending ROI. | 5-10 years, leading to earlier replacement and higher TCO. |

Customized Solutions for Unique Requirements

Understanding that no two industrial or marine projects are identical, we specialize in providing highly customized drum anchor winch for sale solutions. Our engineering team works closely with clients to develop winch drums that precisely match their operational parameters, environmental conditions, and integration requirements.

Customization options include:

- Specific Dimensions and Capacities: Tailoring drum diameter, length, flange dimensions, and rope capacity to fit existing winch frames or new designs with precise load and rope length requirements.

- Material Grades: Selection of specialized steel alloys, such as high-tensile steels for extreme loads or corrosion-resistant alloys for highly aggressive environments, beyond standard Q355/S355JR.

- Groove Profiles: Designing bespoke Lebus or helical groove patterns for unique wire rope diameters or winding characteristics, optimizing performance for specific applications.

- Surface Treatments: Application of advanced coatings, such as ceramic-reinforced epoxies or hot-dip galvanization, for enhanced wear resistance or protection in highly corrosive or abrasive conditions.

- Integration Features: Incorporating specialized shaft interfaces, brake drum mounting surfaces, or sensor mounting points to ensure seamless integration with the overall winch system.

- Certification Requirements: Meeting specific class society rules (e.g., ABS, DNV-GL, LR, BV) and national standards, including comprehensive documentation and third-party inspections.

Our collaborative design process, which often includes Finite Element Analysis (FEA) and 3D modeling, ensures that every customized solution is optimized for performance, safety, and longevity, delivering a product that is perfectly aligned with the client's strategic objectives.

Application Case Studies: Proven Performance

Our commitment to quality and performance is demonstrated through successful deployments across various challenging sectors. These case studies highlight the tangible benefits our drum anchor winch for sale solutions deliver.

-

Case Study 1: Offshore Wind Farm Installation

A major offshore wind farm developer required high-capacity drums for their heavy-lift vessel's anchor winches, operating in severe North Sea conditions. We supplied custom-designed drums, manufactured from A709Gr50 steel, featuring a specialized Lebus groove pattern for 80mm diameter wire rope and a marine-grade epoxy coating system. The client reported a 2.5x increase in wire rope service life and significantly reduced downtime for rope changes, leading to an estimated 15% reduction in operational costs over the project duration. Our drums provided the necessary reliability and robustness, proving invaluable for precise foundation installation and turbine assembly.

-

Case Study 2: Mining Hoist Upgrade

An underground copper mine sought to upgrade its main hoisting system to increase production efficiency and safety. The existing drums suffered from rapid wear and inconsistent rope winding. We engineered and supplied a pair of double drum winch for sale replacements with specialized Q355 steel and precisely machined helical grooves. The improved rope spooling eliminated instances of rope cutting and premature wear, extending wire rope life by over 100%. Mine operators noted a significant improvement in hoist reliability and a marked decrease in unscheduled maintenance, contributing to a 5% increase in daily ore extraction capacity.

-

Case Study 3: Large Shipyard Gantry Crane Modernization

A leading shipyard needed to replace the worn hoist drums on its largest gantry crane, which handles mega-blocks weighing up to 1,000 tons. The challenge was to maintain precise lifting control and accommodate substantial wire rope lengths. Our solution involved supplying drums fabricated from S355JR steel, engineered with deep Lebus grooves for multi-layer winding, ensuring even distribution of stress and minimized rope fatigue. The new drums have been in continuous operation for over five years without any rope-related issues, surpassing the client’s expectations for longevity and performance. The shipyard praised the smooth operation and robust construction, confirming our reputation as a trusted partner.

Frequently Asked Questions (FAQ)

- Q1: What materials are typically used for your winch drums?

- A: We primarily utilize high-strength structural steels such as Q355, S355JR, and A709Gr50 due to their excellent mechanical properties, including high yield strength, tensile strength, and impact resistance. Custom material specifications are also available upon request.

- Q2: How do your rope groove designs extend wire rope life?

- A: Our precision-machined Lebus or helical rope grooves ensure perfect multi-layer winding, which prevents rope crushing, bird-caging, and uneven tension. This significantly reduces localized stress and wear points, extending wire rope service life by 2 to 3 times compared to conventional smooth drums.

- Q3: What testing and certification standards do your products meet?

- A: All our drums undergo rigorous testing, including NDT (UT, MPI), dimensional checks, and material verification. We adhere to international quality standards such as ISO 9001 and specific industry codes like AWS D1.1. We also offer certification by major classification societies like DNV-GL, ABS, and Lloyd's Register upon client request.

- Q4: Can you provide customized drum solutions for unique applications?

- A: Absolutely. Customization is a core part of our service. We can tailor drum dimensions, material grades, groove patterns, surface treatments, and integration features to meet specific project requirements. Our engineering team uses advanced tools like FEA for optimal design.

- Q5: What is the typical lead time for a custom drum anchor winch component?

- A: Lead times vary based on complexity, size, and current production schedules. For standard custom drums, the typical lead time ranges from 6 to 12 weeks from design approval to delivery. Expedited options may be available for urgent projects.

Lead Time, Warranty, and After-Sales Support

Lead Time & Fulfillment:

Our streamlined manufacturing process and efficient supply chain management enable us to provide competitive lead times. For standard components, typical delivery is within 4-6 weeks. For custom-engineered drum anchor winch for sale drums, lead times generally range from 8-16 weeks, depending on design complexity and material procurement. We maintain a transparent communication channel throughout the production and delivery phases, providing regular updates to ensure timely project execution.

Warranty Commitments:

We stand behind the quality and durability of our products. All our winch drums come with a comprehensive warranty against manufacturing defects and material failures under normal operating conditions. The standard warranty period is 12-24 months from the date of commissioning or 18-30 months from delivery, whichever comes first. Extended warranty options are also available, reflecting our confidence in our engineering and manufacturing excellence.

Customer Support & After-Sales Service:

Our commitment to our clients extends far beyond delivery. We offer robust after-sales support, including:

- Technical Consultation: Expert advice on installation, operation, and maintenance.

- Spare Parts Availability: Ensuring prompt access to genuine spare parts to minimize downtime.

- On-site Support: For complex issues or major installations, our engineers can provide on-site technical assistance globally.

- Training Programs: Comprehensive training for client's operational and maintenance personnel.

Our dedicated customer service team is available to assist with any inquiries, ensuring seamless operations and maximum equipment uptime.

Conclusion

The demand for high-performance drum anchor winch for sale components is steadily increasing across critical industrial and marine sectors. By prioritizing advanced material selection, precision manufacturing, and rigorous quality control, we deliver winch drums that not only meet but exceed the stringent requirements of modern applications. Our commitment to extending wire rope life, enhancing safety, and reducing operational costs through superior engineering makes us a trusted partner for B2B clients seeking reliable and durable hoisting and pulling solutions.

We invite you to explore our capabilities and discuss how our customized drum solutions can integrate seamlessly into your operations, contributing to enhanced efficiency, safety, and long-term project success.

References:

- Grand View Research. (2023). Marine Winch Market Size, Share & Trends Analysis Report By Application (Mooring, Anchor Handling), By Vessel Type (Fishing Vessels, Cargo Vessels), By Region, And Segment Forecasts, 2023 - 2030.

- American Society of Mechanical Engineers (ASME). (2020). ASME B30.7-2020: Base Mounted Drum Hoists.

- International Organization for Standardization (ISO). (2018). ISO 4301-1:2016: Cranes -- Classification -- Part 1: General.

- The American Welding Society (AWS). (2020). AWS D1.1/D1.1M:2020: Structural Welding Code - Steel.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025