Precision Double Drum Winch for High Mast Lifting & Maintenance

Industry Trends and the Evolution of Heavy-Duty Winching

The demand for robust, reliable, and precise lifting and pulling solutions in industrial and marine environments has steadily escalated, driven by global infrastructure development, increasing automation, and stringent safety regulations. Industries such as oil & gas, renewable energy, port logistics, and heavy construction consistently require advanced equipment capable of operating under extreme conditions.

A critical component in these demanding applications is the industrial winch, particularly those designed for high-mast operations. The market is witnessing a shift towards more intelligent, energy-efficient, and durable winching systems. This includes advancements in motor control, braking mechanisms, and material science, all aimed at extending service life and enhancing operational safety. Manufacturers are increasingly integrating digital control systems, offering precise load management and remote monitoring capabilities, which are vital for complex tasks like raising and lowering heavy high mast structures.

Among these innovations, the double drum winch for high mast stands out as a preferred solution for its exceptional versatility, enhanced safety, and load distribution capabilities. Its dual drum configuration allows for simultaneous, synchronized lifting operations or independent functions, offering significant operational flexibility over single-drum alternatives in specialized applications.

Core Technical Specifications of Double Drum Winches

Understanding the intricate technical specifications is paramount for selecting the appropriate winching solution. A double drum winch for high mast is engineered for high performance and reliability, featuring a robust design that includes dual independently or synchronously controlled drums, powerful drive systems, and advanced braking mechanisms.

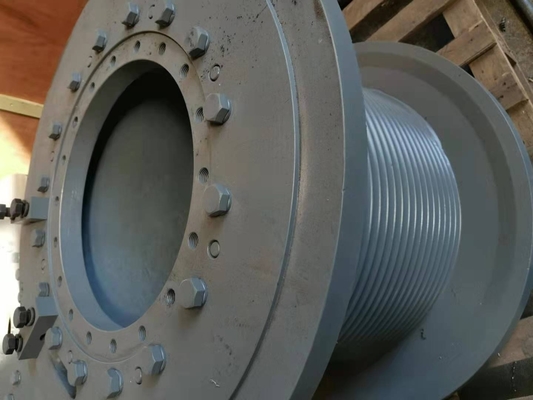

Key components typically include: high-torque electric or hydraulic motors, multi-stage planetary or helical gearboxes for optimal torque multiplication, heavy-duty steel wire ropes, and sophisticated control panels. The drums themselves are often constructed from high-grade carbon steel or alloy steel, precisely machined to accommodate specific rope diameters and lengths, often featuring advanced Lebus grooving for superior rope lay and extended rope life.

The performance parameters, such as rated pull (the maximum pulling force the winch can exert), rope speed (the rate at which the rope is wound or unwound), and rope capacity (the maximum length and diameter of rope the drum can hold), are crucial. Modern systems often incorporate variable frequency drives (VFDs) for precise speed control and soft start/stop capabilities, minimizing mechanical stress and energy consumption.

Typical Product Specification Table

| Parameter | Specification (Typical Range) |

|---|---|

| Rated Pull Capacity | 5 - 100 Tons (Customizable) |

| Rope Speed | 5 - 20 m/min (Variable) |

| Rope Capacity per Drum | 300 - 1500 meters (Ø16-52mm) |

| Motor Power | 37 kW - 300 kW (Electric/Hydraulic) |

| Braking System | Hydraulic/Electromagnetic, Fail-safe design |

| Control System | Local, Remote, PLC/HMI Integration |

| Drum Material | Q345B/Q355B Carbon Steel, Alloy Steel |

| Compliance Standards | ISO, ANSI, DNV, ABS, LR (as per client requirements) |

Manufacturing Process Flow and Quality Assurance

The production of a high-performance double drum winch for high mast involves a rigorous multi-stage manufacturing process, ensuring durability, precision, and adherence to international quality standards. This process begins with meticulous material selection and culminates in comprehensive testing.

Key Stages of Manufacturing:

- 1. Material Selection & Preparation: High-grade carbon steel (e.g., Q345B, Q355B) or alloy steel is chosen for critical components like drums, gears, and frame structures, based on load requirements and environmental exposure. Materials undergo incoming inspection for chemical composition and mechanical properties.

- 2. Cutting & Forming: Raw materials are precisely cut using CNC plasma or laser cutting machines. Heavy plates are formed through bending or rolling to create drum shells and frame sections.

- 3. Machining (Casting & Forging): Complex parts like gear blanks and drum hubs are either precision cast or forged to achieve superior strength and grain structure. Subsequent CNC machining ensures exact dimensions, tight tolerances, and smooth finishes, especially for intricate gear teeth and drum grooves (like Lebus grooving).

- 4. Welding & Fabrication: Components are meticulously welded using qualified procedures (e.g., SAW, MIG/MAG) by certified welders, followed by non-destructive testing (NDT) such as ultrasonic or radiographic inspection to ensure weld integrity.

- 5. Assembly: Motors, gearboxes, braking systems, electrical controls, and hydraulic power units are integrated into the fabricated frame. Precision alignment is critical during this stage.

- 6. Testing & Quality Control: Each winch undergoes a rigorous testing regimen, including static load tests, dynamic load tests, functional tests of all components, brake performance tests, and noise/vibration analysis. Compliance with standards such as ISO 9001 for quality management, and specific industry standards (e.g., DNV, ABS, LR for marine applications, ANSI for industrial) is verified.

- 7. Surface Treatment & Finishing: Components are sandblasted to achieve a clean surface profile, followed by application of marine-grade epoxy coatings or other protective layers to ensure excellent corrosion resistance, extending the service life even in harsh environments.

This stringent process ensures a long service life, typically exceeding 20-30 years with proper maintenance, and offers significant advantages such as energy saving through optimized drive systems and unparalleled corrosion resistance critical for target industries like petrochemical, metallurgy, marine, and water supply & drainage.

Versatile Application Scenarios

The adaptability of a double drum winch for high mast solutions makes it indispensable across a spectrum of demanding industries. Its dual drum capability offers unique operational advantages, enabling complex, coordinated, or sequential tasks that are crucial for safety and efficiency.

- High Mast Lighting Systems: The primary application involves raising and lowering heavy lighting fixtures on high mast poles, often reaching heights of 30 meters or more. The synchronized dual drums ensure a stable, level lift, preventing tilting and damage to expensive lighting arrays during maintenance or installation.

- Marine and Offshore Operations: In marine environments, these winches are critical. A double drum mooring winch provides precise vessel positioning and secure anchoring for ships, barges, and offshore platforms. The ability to manage multiple mooring lines simultaneously enhances safety and operational speed, particularly in dynamic sea conditions.

- Ports and Harbors: For cargo handling, dockside maintenance, and small vessel maneuvering, double drum winches offer the power and control needed for efficient operations. They are often used for tensioning lines, operating gangways, or assisting with heavy lifting tasks.

- Mining and Construction: In open-pit mines or large construction sites, these winches assist with material handling, equipment positioning, and emergency recovery operations. Their robust design withstands the harsh conditions typical of these industries.

- Petrochemical and Energy Facilities: For lifting and positioning heavy components during plant construction, maintenance, or decommissioning, especially where precision and fail-safe operation are paramount, double drum winches are highly valued for their controlled movement capabilities.

The integration of a grooved drum winch design further enhances performance in these scenarios by ensuring optimal rope spooling, reducing wear on the wire rope, and minimizing the risk of rope damage or entanglement, thereby increasing safety and reducing operational downtime.

Technical Advantages and Performance Benefits

The engineering excellence behind a double drum winch for high mast translates into a multitude of significant technical advantages and performance benefits critical for B2B operations. These advantages directly impact operational efficiency, safety, and total cost of ownership.

- Enhanced Safety Features: Modern winches are equipped with multiple layers of safety. This includes fail-safe braking systems that engage automatically upon power loss or emergency stop, overload protection to prevent excessive loads, and limit switches to prevent over-winding or over-lowering. These features significantly reduce the risk of accidents and equipment damage.

- Precision Control and Synchronization: The dual-drum configuration, often coupled with VFDs and advanced control systems, allows for unparalleled precision in lifting and lowering operations. This is crucial for applications requiring perfectly level movement, such as large lighting arrays or delicate equipment. The ability to synchronize drum speeds precisely prevents unbalanced loads and improves operational stability.

- Superior Durability and Reliability: Constructed from robust materials like high-strength carbon steel and featuring heavy-duty gearboxes, these winches are designed for continuous operation in harsh industrial and marine environments. Quality components and stringent manufacturing processes contribute to extended service life and minimal downtime.

- Operational Efficiency and Energy Saving: Optimized motor and gearbox designs, combined with intelligent control systems, ensure efficient power conversion and reduced energy consumption. Features like variable speed control allow operators to match winch speed precisely to the task, preventing unnecessary energy expenditure.

- Corrosion Resistance: For applications in corrosive environments (e.g., marine, chemical plants), winches are treated with specialized anti-corrosion coatings and can be fabricated with corrosion-resistant materials, ensuring long-term performance and reduced maintenance costs.

- Improved Rope Management: Many advanced winches feature a grooved drum winch design, often utilizing Lebus grooving. This system ensures perfect multi-layer rope spooling, prevents rope crossing, crushing, and minimizes wear and tear on the wire rope, thereby prolonging its life and enhancing safety.

Vendor Comparison and Selection Criteria

Choosing the right vendor for a double drum winch for high mast is a critical decision that impacts long-term operational success. A thorough evaluation based on several key criteria is essential for B2B decision-makers. It's not just about the product, but the complete solution offered by the supplier.

Key Evaluation Factors:

- Certification and Compliance: Verify international certifications such as ISO 9001 for quality management, alongside product-specific certifications (e.g., DNV, ABS, Lloyd's Register for marine-grade equipment, CE for European markets). These indicate adherence to global safety and quality standards.

- Customization Capabilities: Assess the vendor's ability to provide tailored solutions. Many high mast applications have unique requirements regarding lifting capacity, rope length, speed, power source, and environmental resistance. A vendor offering robust engineering and design capabilities is invaluable.

- After-Sales Support and Service Network: The longevity and continuous operation of a winch depend heavily on reliable after-sales support, including spare parts availability, technical assistance, on-site service, and maintenance contracts. A global service network can be a significant advantage.

- Technological Innovation: Look for vendors who invest in R&D, offering features like advanced control systems, energy-efficient drives, remote diagnostics, and improved safety mechanisms.

- Track Record and Client References: Evaluate the vendor's experience, particularly in similar applications. Review client testimonials, case studies, and years of service in the industry to gauge their reputation and reliability.

Comparative Overview of Winch Features:

| Feature/Aspect | Industry Standard / Baseline | Advanced Solutions (e.g., LBS Winch) |

|---|---|---|

| Control System | Basic push-button, local control | PLC-based with HMI, VFDs, remote control, diagnostic feedback |

| Drum Grooving | Smooth drum or basic spiral groove | Precision Lebus grooving for optimized rope lay, extended rope life |

| Braking Mechanism | Single mechanical brake | Dual independent hydraulic/electromagnetic, fail-safe, emergency stop |

| Corrosion Protection | Standard industrial paint finish | Multi-layer marine-grade epoxy coating, galvanized components |

| Customization | Limited options for standard models | Extensive engineering for bespoke solutions (drive, capacity, dimensions) |

Customized Solutions and Engineering Expertise

Recognizing that no two industrial projects are exactly alike, the provision of customized solutions is a hallmark of a truly expert winch manufacturer. For complex operations involving a double drum winch for high mast, off-the-shelf products often fall short of specific performance, safety, or environmental requirements.

Specialized engineering teams work closely with clients to understand their unique operational parameters, site conditions, and regulatory compliance needs. This collaborative approach ensures that every aspect of the winch system, from mechanical design to control logic, is perfectly aligned with the project's objectives.

Areas of Customization Include:

- Drive System Configuration: Tailoring between electric (AC/DC with VFDs) and hydraulic drive systems based on available power, speed control requirements, and operating environment (e.g., explosion-proof for hazardous areas).

- Drum Dimensions & Capacity: Custom-designed drum diameters, widths, and Lebus grooving patterns to accommodate specific wire rope types, lengths, and desired line speeds, optimizing for the high mast's structure and load.

- Control Systems: Development of bespoke control panels, integrating advanced PLC programming, HMI interfaces, remote control options (wired or wireless), and data logging capabilities for performance monitoring and diagnostics.

- Material Selection & Coatings: Use of specialized materials (e.g., stainless steel for extreme corrosion resistance, specific alloys for low-temperature operation) and application of advanced marine-grade or chemical-resistant coatings.

- Safety Features: Integration of specialized safety devices such as emergency stop buttons, slack rope detection, automatic load limiting, and advanced braking systems tailored to critical safety integrity levels (SIL).

- Mounting and Integration: Design of custom mounting frames and integration solutions to seamlessly fit the winch into existing structures or complex installations, ensuring stability and operational ergonomics.

This deep level of customization ensures optimal performance, maximum safety, and long-term cost-effectiveness, transforming a standard product into a highly specialized asset that perfectly addresses client challenges.

Real-World Application Case Studies

The practical deployment of a double drum winch for high mast systems demonstrates its critical value in diverse industrial environments. These case studies highlight real-world challenges and how robust winching solutions provide efficient and reliable operations.

Case Study 1: Large-Scale Airport Apron Lighting

Challenge: A major international airport required a highly reliable and precise lifting system for its new generation of high mast lighting poles, which supported heavy LED floodlight arrays. Manual handling was too risky and inefficient for maintenance routines at heights exceeding 40 meters.

Solution: A custom-engineered electric double drum winch for high mast, featuring a 10-ton rated pull and VFD-controlled synchronized drums, was integrated into each high mast system. The winch included a PLC-based control panel for precise speed regulation and automatic slack rope detection.

Outcome: The system dramatically reduced maintenance time from several hours to under 30 minutes per mast. The synchronized dual drums ensured the delicate lighting array remained perfectly level, preventing damage and significantly enhancing safety for ground personnel. The robust construction and marine-grade coating also ensured longevity in varying weather conditions.

Case Study 2: Offshore Platform Mooring System Upgrade

Challenge: An offshore oil platform operating in the North Sea needed to replace its aging mooring winches with a more powerful and reliable solution to accommodate larger supply vessels and improve station-keeping capabilities in harsh sea states. The existing system suffered from frequent rope entanglement due to ungrooved drums.

Solution: Four heavy-duty hydraulic double drum mooring winch units, each with a 50-ton line pull and equipped with Lebus grooved drums, were specified and installed. These units included advanced load monitoring systems and an emergency quick-release mechanism, compliant with DNV standards.

Outcome: The new winches provided superior control over mooring lines, significantly improving vessel stability and reducing the risk of breakaways during adverse weather. The Lebus grooving eliminated rope damage and entanglement, extending the lifespan of the costly wire ropes and reducing maintenance intervals. Operational efficiency for vessel approach and departure was notably enhanced.

Case Study 3: Industrial Water Treatment Plant Lift Station

Challenge: A large industrial water treatment plant needed to regularly lift and lower heavy submersible pumps for routine inspection and maintenance within a deep lift station. The environment was highly corrosive due to chemical exposure and humidity, demanding a winch with exceptional durability and reliability.

Solution: A specialized electric grooved drum winch with a 20-ton capacity, featuring a robust carbon steel construction treated with a multi-layer anti-corrosion coating, was implemented. The drum was precisely grooved for optimal rope lay, crucial for the long drops and retrievals of the pumps. A fully enclosed motor and IP67-rated control system ensured protection against environmental ingress.

Outcome: The winch provided reliable, controlled, and safe handling of the heavy pumps in a corrosive atmosphere. The enhanced corrosion resistance significantly extended the winch's operational life compared to previous equipment, minimizing the need for frequent replacements and reducing overall maintenance costs. The grooved drum ensured smooth operation without rope damage over hundreds of cycles.

Frequently Asked Questions (FAQ)

Q1: What is the typical service life of a double drum winch for high mast?

A1: With proper installation, regular maintenance, and operation within its rated capacity, a high-quality double drum winch can have a service life of 20 to 30 years or more. Critical factors include material quality, environmental conditions, and adherence to maintenance schedules.

Q2: What maintenance is required for these winches?

A2: Routine maintenance typically involves lubricating gears and bearings, inspecting wire ropes for wear and damage, checking electrical connections and control systems, verifying brake functionality, and inspecting structural components for corrosion or fatigue. A detailed maintenance schedule is provided with each unit.

Q3: Can these winches operate in extreme weather conditions?

A3: Yes, high-quality industrial winches are designed for extreme environments. They can be equipped with features like temperature-resistant lubricants, specialized heating/cooling systems, IP-rated enclosures for electrical components, and marine-grade anti-corrosion coatings to ensure reliable operation in high heat, freezing temperatures, or corrosive atmospheres.

Q4: How do I choose the correct capacity for my application?

A4: Selecting the correct capacity involves a thorough assessment of the maximum load to be lifted, desired line speed, required rope length, duty cycle, and any environmental factors. It is recommended to consult with our engineering team, who can provide expert guidance based on your specific project requirements.

Lead Time, Warranty, and After-Sales Support

At LBS Winch, we prioritize transparency and customer satisfaction throughout the entire product lifecycle, from initial inquiry to long-term operation. Understanding our commitments regarding lead times, warranty coverage, and after-sales support is crucial for our B2B partners.

Lead Time & Fulfillment:

Standard models of our winches typically have a lead time of 8-12 weeks from confirmed order to factory dispatch, depending on current production schedules. For highly customized solutions, lead times may extend to 16-24 weeks, as they involve detailed engineering, specialized material procurement, and extensive testing. We maintain clear communication throughout the manufacturing process, providing regular updates on production milestones and estimated delivery dates.

Warranty Commitments:

All LBS Winch products, including our double drum winch for high mast, are backed by a comprehensive 12-month standard warranty from the date of commissioning or 18 months from delivery, whichever comes first. This warranty covers defects in materials and workmanship under normal operating conditions. Extended warranty options are available and can be tailored to specific project needs, providing additional peace of mind for long-term investments.

Customer Support & After-Sales Service:

Our commitment extends beyond delivery. LBS Winch offers a full spectrum of after-sales support services designed to ensure the continuous and efficient operation of your equipment:

- Technical Assistance: Our dedicated technical support team is available to provide expert guidance, troubleshooting, and operational advice.

- Spare Parts Management: We maintain a robust inventory of genuine spare parts to minimize downtime. Critical components can be dispatched swiftly to any global location.

- On-Site Service & Maintenance: For complex issues or scheduled preventive maintenance, our certified technicians are available for on-site visits and assistance.

- Training Programs: We offer comprehensive training for your operational and maintenance staff, ensuring they are proficient in the safe and efficient use of our winching systems.

Conclusion

The strategic integration of a high-quality double drum winch for high mast applications is a critical investment for industries demanding robust, precise, and reliable lifting and pulling capabilities. Its advanced engineering, dual-drum versatility, and inherent safety features ensure optimal performance in the most challenging environments, from high mast lighting to complex marine mooring operations. By focusing on customization, adhering to stringent manufacturing standards, and providing comprehensive after-sales support, industry leaders deliver solutions that not only meet but exceed the evolving demands of modern industrial operations, ensuring long-term operational efficiency and enhanced safety.

References

- ISO 9001:2015 Quality management systems – Requirements. International Organization for Standardization.

- ANSI/ASME B30.7-2016: Winches and Hoists (US Standard). American Society of Mechanical Engineers.

- DNV GL: Rules for Classification of Ships. Det Norske Veritas Germanischer Lloyd.

- American Bureau of Shipping (ABS): Guide for Certification of Lifting Appliances.

- Lloyd's Register: Code for Lifting Appliances in a Marine Environment.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025