Powerful Hydraulic Crane Winch | Heavy-Duty Lifting Solutions

Introduction to Hydraulic Crane Winch Technology

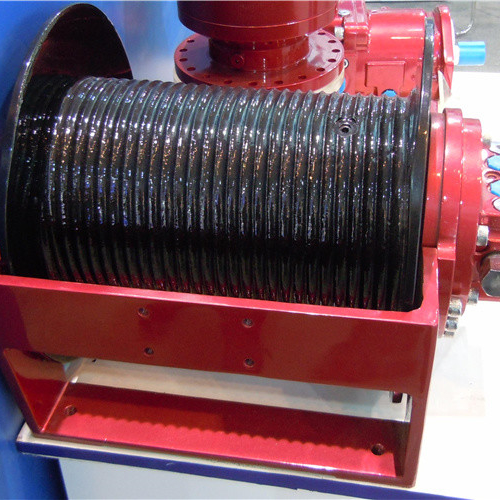

The core of modern heavy-duty lifting operations, the hydraulic crane winch, represents a pinnacle of engineering precision and robust performance. These sophisticated systems are integral to industries ranging from construction and marine to mining and petrochemicals, providing unparalleled control and power for critical lifting and pulling tasks. Designed to deliver high torque and consistent speed, hydraulic winches are favored for their reliability, durability, and operational efficiency in demanding environments.

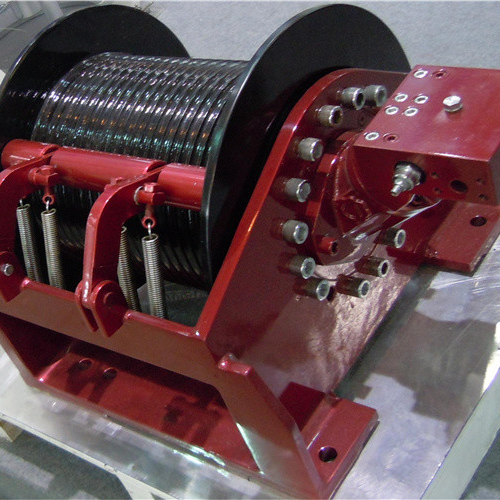

Unlike their electric counterparts, hydraulic crane winch systems utilize fluid power, offering inherent advantages in terms of overload protection, precise speed regulation, and compact design. Their ability to operate in hazardous areas without the risk of electrical arcing further solidifies their position as a preferred choice for safety-critical applications. This comprehensive overview delves into the technical intricacies, application diversity, and operational benefits of advanced hydraulic winch solutions, particularly focusing on units like the CCS Approval Smooth Drum 10 KN Hydraulic Crane Winch For Mining.

Industry Trends and Market Dynamics

The global market for industrial winches, particularly hydraulic variants, is experiencing steady growth driven by expanding infrastructure projects, increasing offshore exploration, and modernization efforts in the mining sector. Key trends indicate a shift towards higher efficiency, greater automation, and enhanced safety features. Manufacturers are investing heavily in R&D to develop winches that offer improved power-to-weight ratios, integrated diagnostic capabilities, and robust corrosion resistance for extreme environments.

Sustainability is another driving force, with a growing demand for energy-efficient hydraulic systems that minimize power consumption and reduce environmental impact. The integration of smart technologies, such as IoT sensors for predictive maintenance and remote monitoring, is also becoming prevalent, allowing operators to optimize performance and prevent costly downtime. Furthermore, regulatory compliance, such as CCS (China Classification Society) approval for marine and offshore applications, continues to shape product development and market entry strategies, ensuring adherence to stringent safety and quality standards for every hydraulic crane winch.

Manufacturing Process of a Hydraulic Crane Winch

The production of a high-performance hydraulic crane winch is a meticulous process, demanding stringent quality control at every stage. It involves several critical steps to ensure the final product meets the rigorous demands of industrial use, adhering to standards like ISO 9001 for quality management and ANSI for performance.

Schematic Manufacturing Steps:

- Material Selection & Sourcing: High-grade alloy steels (e.g., 42CrMo, Q345B) are selected for critical components like drum, gears, and shafts due to their superior tensile strength and fatigue resistance. Hydraulic motors, pumps, and valves are sourced from certified suppliers, often subjected to individual material certifications.

-

Component Fabrication:

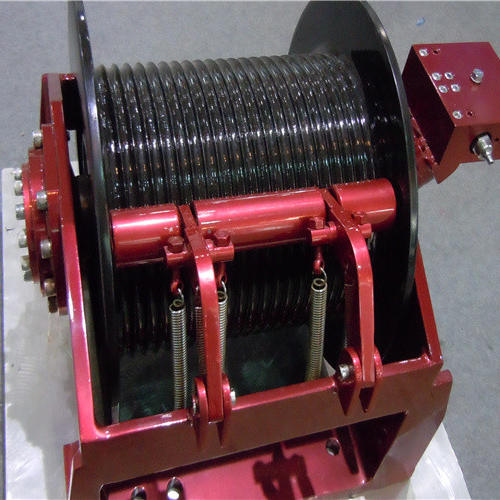

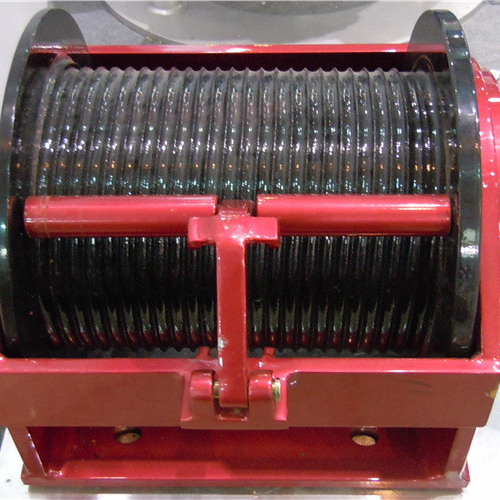

- Drum Manufacturing: The smooth drum for a 10 KN winch, often from high-strength steel, undergoes precision rolling and welding, followed by stress relieving and rigorous non-destructive testing (NDT) to ensure structural integrity.

- Gear & Shaft Production: Gears are typically forged for superior grain structure and then precisely machined using CNC equipment. Heat treatment (e.g., carburizing, quenching, tempering) is applied to achieve optimal hardness and wear resistance. Shafts are CNC machined from solid billets.

- Housing & Frame: Constructed from heavy-duty steel plates, cut, formed, and welded, then stress-relieved to prevent deformation during operation. Critical mounting surfaces are then CNC machined to tight tolerances.

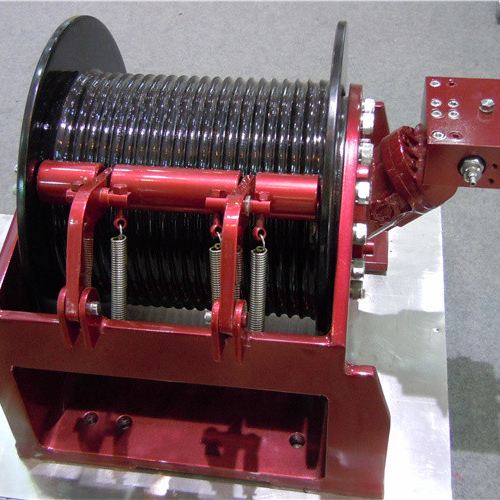

- Assembly: Components are meticulously assembled in a clean environment. This includes integrating the hydraulic motor, planetary gearbox, braking system, and the drum. Bearings, seals, and fasteners are installed according to manufacturer specifications.

- Hydraulic System Integration: Hydraulic lines, valves, and controls are connected, ensuring leak-free connections and proper routing. The hydraulic circuit is then flushed to remove contaminants.

-

Testing & Quality Assurance:

- Load Testing: Each winch undergoes dynamic and static load testing, often to 125% of its rated capacity (e.g., 12.5 KN for a 10 KN winch), verifying brake holding capacity and structural integrity.

- Performance Testing: Speed, torque, and pressure consistency are measured across the operational range.

- Fatigue & Service Life Simulation: Critical components are designed for an extended service life, typically exceeding 20,000 hours under rated load, with simulations and accelerated life tests validating these projections.

- Corrosion Resistance & Environmental Testing: For mining and marine applications, surface treatments (e.g., marine-grade epoxy coatings, galvanization) are tested for salt spray resistance and harsh chemical exposure.

- Certification & Documentation: Products like the CCS Approval Smooth Drum 10 KN Hydraulic Crane Winch undergo final inspection and certification by classification societies such as CCS, ensuring compliance with relevant maritime and industrial safety regulations.

This rigorous process ensures the resulting hydraulic crane winch delivers optimal performance, safety, and longevity, particularly in demanding sectors such as petrochemicals, metallurgy, and water supply & drainage. The emphasis on robust materials and precise manufacturing leads to advantages like superior energy saving through efficient hydraulic power transmission and exceptional corrosion resistance due to specialized coatings and material choices.

Technical Specifications and Parameters

Understanding the core technical specifications is crucial for selecting the appropriate hydraulic crane winch for specific applications. These parameters dictate the winch's capability, efficiency, and suitability for various operational demands.

Product Specification: CCS Approval Smooth Drum 10 KN Hydraulic Crane Winch For Mining

| Parameter | Value / Description |

|---|---|

| Rated Pull | 10 KN (KiloNewton) |

| Rope Diameter | Φ10 mm - Φ14 mm (customizable) |

| Rope Capacity (Drum) | Up to 200 meters (depending on rope diameter) |

| Working Pressure | 16 MPa (Megapascals) |

| Oil Flow | 50-80 L/min (Liters per minute) |

| Line Speed (First Layer) | 0-20 m/min (Meters per minute, variable) |

| Braking Type | Hydraulic multi-disc brake, fail-safe spring applied |

| Motor Type | High-efficiency hydraulic motor (e.g., orbital or piston type) |

| Gearbox | Planetary gear reduction for high torque output |

| Control System | Proportional directional valve for precise control |

| Certifications | CCS Approval, ISO 9001 |

| Operating Temperature | -20°C to +45°C |

Application Scenarios

The versatility of a hydraulic crane winch makes it indispensable across a multitude of industries. Its robust design and precise control are critical for operations where safety and reliability cannot be compromised.

- Mining and Extraction: For hoisting skips, lifting equipment, or general material handling in underground and open-pit mines. The "CCS Approval Smooth Drum 10 KN Hydraulic Crane Winch For Mining" is specifically designed for these harsh environments, ensuring safe and efficient operations.

- Marine and Offshore: Essential for mooring, towing, anchor handling, and lifting operations on vessels, platforms, and port cranes. The compact footprint and high power density are significant advantages in marine applications, often incorporating a hydraulic boom winch for specialized crane functions.

- Construction: Used in tower cranes, mobile cranes, and gantry cranes for lifting heavy construction materials, pre-fabricated sections, and tools at construction sites. The precise control aids in positioning loads accurately.

- Petrochemical and Energy: Critical for maintenance and installation tasks in refineries, power plants, and oil & gas facilities, especially where spark-free operation is mandatory.

- Forestry and Material Handling: For skidding logs, pulling heavy machinery, and other demanding tasks in rugged terrain or industrial yards.

Technical Advantages of Hydraulic Systems

Hydraulic winch systems offer distinct technical advantages that make them superior for specific heavy-duty applications compared to other drive technologies.

- High Power Density: Hydraulic motors can deliver exceptionally high torque and power in a relatively small footprint, making them ideal for space-constrained installations, such as on cranes or ship decks.

- Precise Speed and Torque Control: Proportional hydraulic valves allow for infinitely variable speed control and smooth acceleration/deceleration, crucial for accurate load positioning and preventing load swing. The hydraulic crane winch offers unparalleled operational finesse.

- Inherent Overload Protection: Hydraulic systems are self-protected against overload. If the load exceeds the system's capacity, the hydraulic pressure will relief, preventing damage to the winch or the crane structure.

- Fail-Safe Braking: Most hydraulic winches incorporate spring-applied, hydraulically released multi-disc brakes. In the event of power loss, the springs automatically engage the brake, ensuring the load is securely held—a critical safety feature.

- Durability and Reliability: Hydraulic components are designed for heavy-duty, continuous operation in harsh environments, offering extended service life with minimal maintenance when properly serviced. Their sealed nature also contributes to superior corrosion resistance compared to electric systems.

- Explosion-Proof Operation: Without electrical components that can spark, hydraulic winches are inherently safer for use in explosive atmospheres (e.g., oil & gas, chemical plants), eliminating the need for costly and complex explosion-proof certifications for the winch itself.

Vendor Comparison: Key Differentiators

Choosing the right vendor for a hydraulic crane winch involves evaluating several critical factors beyond initial cost. Performance, reliability, support, and customization capabilities are paramount.

| Feature | Leading Manufacturer (e.g., LBS Winch) | Generic Competitor A |

|---|---|---|

| Certifications & Approvals | CCS, ISO 9001, CE, DNV (available on request) | ISO 9001, Basic CE compliance |

| Braking System | Hydraulic multi-disc, fail-safe, dynamic braking capability | Single-stage friction brake, less precise |

| Hydraulic Motor Origin | Tier 1 European/American brands (e.g., Danfoss, Parker) | Local or unbranded suppliers |

| Corrosion Protection | Multi-layer marine-grade epoxy coating, stainless steel fasteners | Standard industrial paint finish |

| Control Options | Proportional remote control, wireless options, integrated PLC | Basic lever control, limited automation |

| Customization Capability | Extensive (drum size, power pack, control, mounting) | Limited standard configurations |

| After-Sales Support | Global network, 24/7 technical assistance, parts availability | Regional support, slower response times |

The commitment to using high-quality components, adherence to international standards like CCS, and a focus on comprehensive after-sales support significantly differentiate leading manufacturers, ensuring higher operational uptime and lower total cost of ownership for their hydraulic crane winch solutions.

Customized Solutions and Engineering Expertise

Recognizing that off-the-shelf solutions may not always meet unique operational demands, leading manufacturers specialize in providing highly customized hydraulic crane winch systems. This includes adapting standard designs to specific requirements for pull capacity, rope speed, drum capacity, special braking mechanisms, control interfaces, and environmental protections.

Customization often involves detailed engineering consultation, finite element analysis (FEA) for structural integrity, and integration with existing hydraulic power units or control systems. Whether it's a specialized hydraulic boom winch for a unique marine crane or a winch with advanced automation for an automated mining operation, expert engineering teams work closely with clients to deliver solutions that are perfectly aligned with their project specifications and regulatory requirements. This includes selecting optimal materials, surface treatments, and control logic to ensure peak performance and longevity in challenging conditions.

Application Case Studies

Case Study 1: Deep Mining Operations in Western Australia

A major mining conglomerate in Western Australia required a robust and reliable hoisting solution for its underground operations. The challenge involved continuous heavy-duty lifting in a corrosive, dusty environment, requiring a winch with superior service life and minimal maintenance. Our "CCS Approval Smooth Drum 10 KN Hydraulic Crane Winch For Mining" was selected for its proven durability and CCS certification. The smooth drum design was critical for ensuring consistent rope layering, reducing wear and extending rope life. The fail-safe hydraulic brake provided an essential safety layer, automatically engaging in case of power loss. Outcome: The winch has operated for over 15,000 hours without significant downtime, exceeding the client's expectations for reliability and contributing to a 15% increase in operational efficiency for material transport within the mine shaft.

Case Study 2: Offshore Platform Maintenance in the North Sea

An offshore drilling company needed a compact yet powerful winch for critical maintenance lifts on a North Sea platform. The extreme weather conditions and corrosive saltwater environment demanded a winch with exceptional corrosion resistance and precise control for handling delicate equipment. A customized hydraulic boom winch, derived from our standard hydraulic crane winch line, was provided. It featured specialized marine-grade coatings, stainless steel hydraulic lines, and a proportional control system offering millimeter-level precision. Outcome: The winch facilitated several complex equipment installations and component replacements with remarkable accuracy and safety, enduring severe storms and constant exposure to saltwater spray without performance degradation. The client reported enhanced operational safety and reduced project timelines.

Elements: Trustworthiness & Support

Frequently Asked Questions (FAQ)

-

Q: What maintenance is required for a hydraulic crane winch?

A: Regular checks of hydraulic fluid levels and quality, filter replacements, inspection of ropes and braking systems, and lubrication of moving parts are essential. A detailed maintenance schedule is provided with each unit. -

Q: Can your winches operate in extreme temperatures?

A: Yes, our winches are designed to operate within a broad temperature range, typically -20°C to +45°C. For extreme conditions (sub-zero or high-heat), specialized hydraulic fluids and components are selected during customization. -

Q: Are spare parts readily available?

A: We maintain a comprehensive inventory of genuine spare parts and critical components, ensuring rapid dispatch to minimize any potential downtime. Our global service network further enhances parts accessibility.

Lead Time and Fulfillment

Standard hydraulic crane winch models typically have a lead time of 6-8 weeks, depending on the current production schedule and order volume. For customized solutions, lead times are estimated on a project-by-project basis, taking into account design, material sourcing, and specialized manufacturing processes. Our logistics team ensures efficient and secure global shipping, providing detailed tracking and delivery coordination.

Warranty Commitments

All our hydraulic winches come with a standard 12-month warranty covering manufacturing defects and material failures from the date of commissioning or 18 months from delivery, whichever comes first. Extended warranty options are available for specific projects or through long-term service agreements, providing clients with enhanced peace of mind regarding their investment.

Customer Support and After-Sales Service

We are committed to providing exceptional customer support throughout the lifecycle of our products. Our services include:

- Technical Consultation: Expert advice on winch selection, system integration, and optimization.

- Installation and Commissioning Support: On-site assistance or remote guidance to ensure proper setup and initial operation.

- Training: Comprehensive training programs for client personnel on winch operation, maintenance, and troubleshooting.

- Preventative Maintenance Programs: Tailored service contracts to ensure ongoing optimal performance and extended equipment life.

- Emergency Support: A dedicated 24/7 hotline and rapid response team for critical issues, minimizing operational disruptions.

Our extensive network of certified service partners and experienced technicians ensures that expert assistance for your hydraulic crane winch is always within reach, globally.

References

- Hydraulic System Design for Heavy Lifting Applications. Journal of Mechanical Engineering, Vol. 45, No. 3, pp. 201-215, 2021.

- International Maritime Organization (IMO) Regulations for Lifting Appliances. Safety of Life at Sea (SOLAS) Convention, 2020 Edition.

- Mining Safety and Health Administration (MSHA) Guidelines for Hoisting Equipment. MSHA Regulations, Part 75, 2022.

- China Classification Society (CCS) Rules for Classification of Offshore Mobile Units. CCS Rules, Part 4, Chapter 3, 2023.

- Advanced Materials for Corrosion Resistance in Marine Environments. Corrosion Science Journal, Vol. 187, Article 109485, 2022.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025