Powerful 20000 lb Electric Winch | Heavy Duty & Reliable

Unlocking Industrial Efficiency with the 20000 lb Electric Winch

In heavy industrial operations, the demand for robust, reliable, and precise material handling equipment is paramount. The 20000 lb electric winch stands as a cornerstone technology, engineered to manage substantial loads with exceptional control and safety. Designed for rigorous environments, this class of electric winches is critical in sectors ranging from petrochemical and metallurgy to marine and construction, where lifting, pulling, and positioning heavy components are daily necessities.

Unlike smaller counterparts like a small electric winch 120v or a 2 ton electric winch, a 20000 lb capacity unit (approximately 9 metric tons) requires advanced engineering, durable materials, and sophisticated control systems to ensure consistent performance and operational safety under extreme conditions. This article delves into the technical intricacies, application versatility, and strategic advantages of deploying such powerful lifting solutions.

Industry Trends Shaping Winch Technology

The industrial winch market is currently undergoing significant transformation, driven by a confluence of technological advancements, evolving regulatory landscapes, and increasing demands for operational efficiency. Key trends include:

- Automation and Smart Controls: The integration of Variable Frequency Drives (VFDs), Programmable Logic Controllers (PLCs), and remote control systems is becoming standard. This allows for precise speed control, soft start/stop capabilities, and intelligent load management, significantly reducing operator fatigue and increasing safety.

- Enhanced Safety Standards: Global and regional safety regulations (e.g., ANSI B30.7, OSHA, CE) continue to drive innovation in braking systems, overload protection, emergency stop mechanisms, and fault diagnostics. This ensures that heavy-duty equipment like the 20000 lb electric winch operates within strict safety parameters.

- Energy Efficiency: With rising energy costs and environmental concerns, there's a strong push towards more energy-efficient motors (IE3/IE4 ratings) and regenerative braking systems, reducing operational expenses and carbon footprints.

- Modularity and Customization: Manufacturers are offering highly modular designs that can be easily customized to meet specific application requirements, including specialized drum configurations (like the Galvanized Steel Wire Rope Winch Drum Quadruplex), explosion-proof ratings (ATEX), and marine-grade corrosion resistance. This is a clear advantage over off-the-shelf solutions for small electric winch 120v applications which often lack such adaptability.

- IoT and Predictive Maintenance: The incorporation of sensors and data analytics for predictive maintenance helps anticipate failures, optimize service schedules, and minimize costly downtime, shifting from reactive to proactive maintenance strategies.

These trends not only enhance the performance and safety of heavy-duty winches but also provide a competitive edge through improved total cost of ownership (TCO) and operational reliability.

Technical Specifications of a 20000 lb Electric Winch

Understanding the technical parameters is crucial for selecting the appropriate 20000 lb electric winch for specific industrial demands. These specifications dictate the winch's capacity, speed, durability, and suitability for various operating environments. Below is a representative table outlining typical parameters for a high-performance 20000 lb electric winch:

| Parameter | Specification | Description/Notes |

|---|---|---|

| Rated Line Pull | 20,000 lbs (9,072 kg) | Maximum single line capacity. Can be doubled with reeving. |

| Motor Power | 15 - 22 kW (20 - 30 HP) | Industrial-grade AC motor, typically 3-phase. |

| Voltage | 380V / 400V / 415V / 440V (3-Phase) | Common industrial voltages. Requires adequate power supply. |

| Line Speed | 3 - 12 m/min (10 - 40 ft/min) | Variable speed control often via VFD. |

| Wire Rope Diameter | 16 - 20 mm (0.63 - 0.79 inches) | High-strength galvanized or stainless steel wire rope. |

| Drum Capacity | Up to 500 meters (1,640 ft) | Depends on rope diameter and drum size (e.g., Galvanized Steel Wire Rope Winch Drum). |

| Braking System | Electro-magnetic (fail-safe) or Hydraulic | Redundant braking for ultimate safety. |

| Duty Cycle | FEM 2m (M5) / M6, ISO A4 / A5 | Designed for heavy-duty, continuous operation. |

| Ingress Protection (IP) | IP55 (Standard), IP65 (Optional) | Protection against dust and water jets, suitable for outdoor/harsh environments. |

| Control System | Wired pendant, Wireless remote, PLC integration | Versatile control options for various operational needs. |

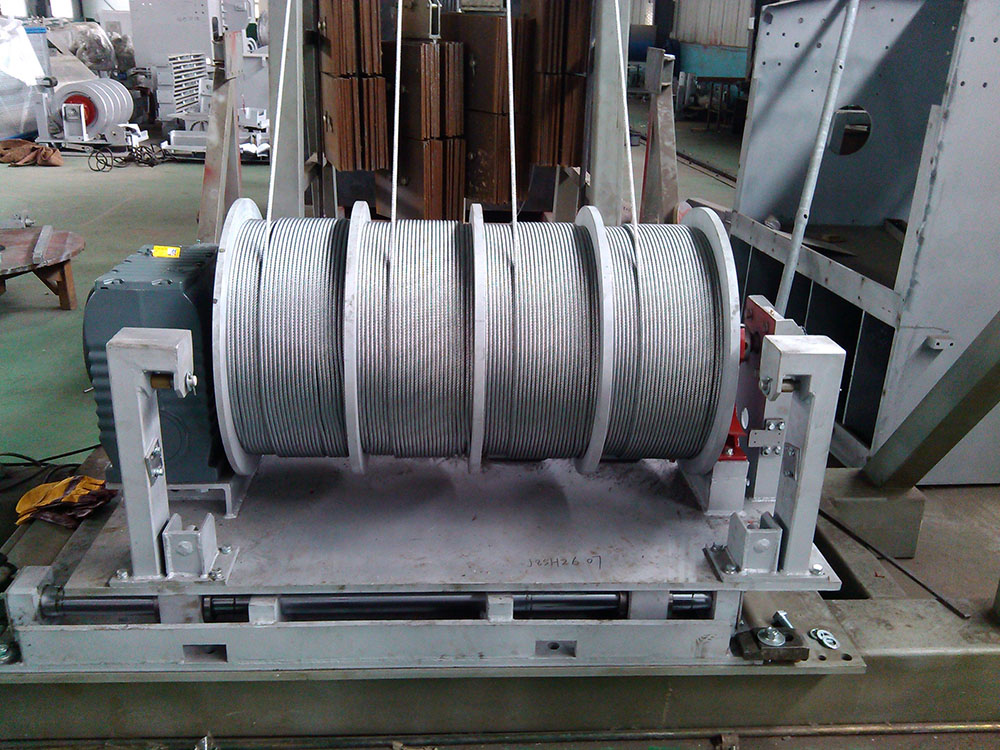

Figure 1: High-capacity electric winch showcasing robust construction.

Manufacturing Process of a High-Capacity Electric Winch

The production of a 20000 lb electric winch is a meticulous process, demanding stringent quality control and advanced engineering techniques to ensure durability, safety, and optimal performance. This multi-stage process integrates material science with precision manufacturing:

Key Stages in Winch Manufacturing:

- 1. Design and Engineering: Utilizing advanced CAD/CAE software, engineers perform finite element analysis (FEA) to simulate stress distribution, optimize component geometries, and ensure the winch meets or exceeds design factors for its rated load. This stage defines material selection, gear ratios, and overall structural integrity.

- 2. Material Sourcing & Preparation:

- Wire Rope: High-tensile strength galvanized steel wire rope, pre-stretched and factory-lubricated for extended service life.

- Drum: Precision-machined cast steel or fabricated steel drum, often with internal reinforcing ribs, and possibly galvanized for enhanced corrosion resistance, especially crucial for a Galvanized Steel Wire Rope Winch Drum.

- Gears: Forged alloy steels (e.g., 42CrMo, 20CrMnTi) for planetary or helical gear sets, ensuring high torque transmission and wear resistance.

- Frame: Heavy-duty fabricated steel sections (e.g., Q345B, S355JR) for structural rigidity.

- 3. Component Fabrication & Machining:

- Casting/Forging: Large components like gear blanks and drum hubs are cast or forged to achieve superior mechanical properties and internal integrity.

- CNC Machining: Critical components, including gear teeth, drum grooves, and shaft bearing surfaces, undergo high-precision CNC machining to achieve tight tolerances (e.g., DIN Class 6 for gears) essential for smooth operation and longevity.

- Welding: Structural frame components are assembled using advanced welding techniques (e.g., MIG/MAG, submerged arc welding) by certified welders, followed by non-destructive testing (NDT) such as ultrasonic or magnetic particle inspection.

- 4. Surface Treatment: Components exposed to harsh environments undergo specialized treatments. This often includes hot-dip galvanizing for drums and other steel parts for superior corrosion resistance, followed by industrial-grade epoxy or polyurethane painting for the main frame.

- 5. Assembly: Motors, gearboxes, brakes, control panels, and the drum assembly are meticulously integrated. Precision alignment of all rotational components is critical to prevent premature wear and ensure efficient power transmission.

- 6. Testing & Quality Control: Every 20000 lb electric winch undergoes rigorous testing:

- Static Load Test: Typically 125% of rated capacity for a specified duration.

- Dynamic Load Test: Up to 110% of rated capacity, cycling through full speed and braking sequences.

- Functional Testing: Verifying motor performance, brake effectiveness, control system responsiveness, and safety interlocks.

- Certifications: Compliance with international standards such as ISO 9001 (Quality Management), CE Marking (European Safety), ANSI B30.7 (Winches), and often specific industry certifications like ATEX for hazardous environments.

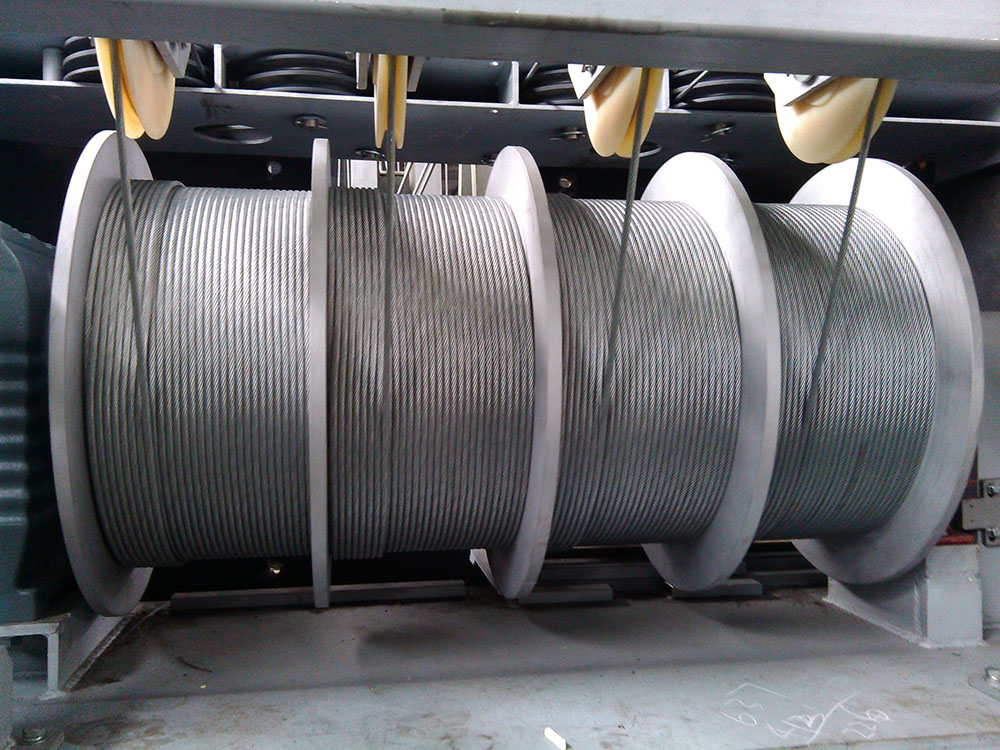

Figure 2: Close-up of winch components during assembly, highlighting precision engineering.

The expected service life for a properly maintained industrial 20000 lb electric winch can exceed 20 years, depending on the duty cycle, environmental conditions, and adherence to maintenance schedules. Regular inspections and timely replacement of wear parts, especially the wire rope, are critical.

Technical Advantages and Performance Edge

A well-engineered 20000 lb electric winch delivers a multitude of technical advantages that translate directly into operational benefits for B2B users:

- Superior Power and Torque: Designed for high-duty cycles, these winches offer immense pulling power, capable of handling loads that would overwhelm a 2 ton electric winch, ensuring efficient movement of massive equipment.

- Precision Control and Variable Speed: Equipped with VFDs, operators can achieve smooth, infinitely variable speed control, crucial for delicate positioning tasks and preventing load swing, leading to safer operations and reduced material damage.

- Enhanced Safety Mechanisms: Incorporating redundant braking systems (e.g., motor brake + independent mechanical brake), overload limiters, slack rope detection, and emergency stop functions, these winches set high standards for operational safety.

- Robust Durability and Corrosion Resistance: Constructed from heavy-gauge steel, with critical components often galvanized or coated with marine-grade paints, these winches are built to withstand corrosive chemicals, extreme temperatures, and abrasive environments, ensuring a long operational lifespan.

- Energy Efficiency: Modern electric motors (e.g., IE3/IE4 efficiency classes) coupled with optimized gearboxes minimize energy consumption, reducing operational costs over the winch's lifetime. Regenerative braking systems can also feed energy back into the grid during lowering operations.

- Reduced Maintenance Requirements: High-quality components, sealed gearboxes, and robust bearings contribute to extended maintenance intervals, leading to less downtime and lower maintenance costs.

These advantages position the 20000 lb electric winch as an indispensable asset for any heavy industrial operation seeking to maximize productivity while upholding the highest safety standards.

Diverse Application Scenarios

The versatility of the 20000 lb electric winch makes it an ideal solution across a broad spectrum of industries, where heavy-duty lifting and pulling are non-negotiable requirements:

- Petrochemical Industry: Essential for lifting and positioning heavy valves, pipe sections, reactor components, and heat exchangers during plant construction, maintenance, and turnaround projects. The ability to operate in hazardous environments (with ATEX certification) is crucial.

- Metallurgy and Steel Mills: Used for handling heavy steel coils, furnace doors, ladle transfer cars, and other massive components. The winch's robust design can withstand high temperatures and abrasive dust present in these facilities.

- Water Supply & Drainage Systems: Deploys and retrieves large submersible pumps, operates heavy sluice gates in dams and canals, and assists in maintenance of large water treatment equipment. Corrosion resistance is paramount here.

- Construction and Infrastructure: Crucial for hoisting heavy construction materials, pre-fabricated sections, and formwork on large building sites, bridge construction, and tunneling projects. Offers reliable vertical and horizontal pulling power.

- Marine and Offshore: Utilized on vessels and offshore platforms for mooring, anchor handling, general cargo lifting, and launching/retrieving ROVs or subsea equipment. Marine-grade protection ensures longevity in saltwater environments.

- Mining Operations: Employed for hauling ore cars, moving heavy machinery within mines, and assisting with shaft maintenance.

Figure 3: An industrial winch deployed in a heavy-duty lifting application.

In each scenario, the winch's reliability, precise control, and high safety margins significantly contribute to energy saving by optimizing operational workflows and reducing the need for multiple smaller lifts, minimizing downtime, and ensuring the safety of personnel and assets.

Vendor Comparison for 20000 lb Electric Winches

When investing in a critical piece of equipment like a 20000 lb electric winch, a thorough vendor comparison is essential. While general features are often similar, differentiating factors lie in build quality, customization options, control systems, and post-sales support. Below is a comparative overview of hypothetical vendor offerings:

| Feature | Vendor A (Standard Industrial) | Vendor B (Budget-Oriented) | Our Solution (Premium/Custom) |

|---|---|---|---|

| Motor Type | Standard Induction Motor (IE2) | Basic Induction Motor (IE1) | High-Efficiency IE3/IE4 VFD Motor |

| Control System | Wired Pendant, Basic PLC | Simple Wired Pendant | Advanced PLC, Wireless Remote, HMI, IoT-ready |

| Braking System | Single Electro-magnetic Disc Brake | Spring-applied, electrically released brake | Dual Redundant Electro-hydraulic/Electro-magnetic, Fail-Safe |

| Corrosion Protection | Standard Industrial Paint | Basic Primer & Topcoat | Hot-Dip Galvanized Drum, Multi-layer Epoxy Marine Coating (RAL specified) |

| Certifications | CE Mark, ISO 9001 | Basic QA, CE (self-declared) | CE, ISO 9001, ANSI B30.7, ATEX (Optional), DNV/Lloyd's (Marine Optional) |

| Customization Level | Limited (standard sizes) | Very Low | Extensive (drum length, speed, ATEX, specialized controls) |

| Warranty | 1 Year Standard | 6 Months | 2 Years Standard, Extendable to 5 Years |

Figure 4: A custom-designed winch assembly demonstrating tailored features.

Customized Solutions for Unique Challenges

While standard configurations of the 20000 lb electric winch meet many industrial needs, specialized applications often demand tailor-made solutions. Our engineering team excels in developing highly customized winches that precisely match unique operational parameters and environmental constraints. This goes beyond what's typically available even for a robust 2 ton electric winch, extending to complex systems and challenging integrations.

Customization options include:

- Explosion-Proof (ATEX) Compliance: For petrochemical plants, oil & gas platforms, and chemical processing facilities where flammable gases or dust are present, winches can be designed and certified to ATEX directives.

- Extreme Environmental Adaptations: This includes specialized heating or cooling systems for operations in arctic or desert conditions, enhanced IP ratings (e.g., IP66/IP67) for complete dust and water immersion protection, or marine-grade finishes for saltwater exposure.

- Specialized Drum Configurations: Custom drum lengths, diameters, and groove patterns to accommodate specific wire rope capacities or multi-line reeving (e.g., duplex, quadruplex hoist drums), or integrated with specific wire rope management systems.

- Advanced Control Integration: Seamless integration with existing Plant Control Systems (DCS/SCADA), sophisticated HMI panels, dynamic load monitoring, and anti-sway technology for crane integration.

- Hydraulic or Pneumatic Power Options: While primarily electric, certain environments or applications may benefit from hydraulic or pneumatic power systems for intrinsically safe operations or where electrical power is not readily available.

Our process involves close collaboration with clients, detailed engineering reviews, and iterative design to ensure the final product not only meets but exceeds specific operational requirements and safety expectations.

Application Case Studies & Customer Experience

Real-world application demonstrates the transformative impact of a robust 20000 lb electric winch. Our experience working with leading industrial clients underscores the value of reliability, safety, and performance.

Case Study 1: Petrochemical Plant Expansion in the Middle East

A major petrochemical company embarked on expanding its refinery capacity, requiring precise lifting and positioning of reactor components weighing up to 8 metric tons in a Class I, Division 2 hazardous area. We supplied a custom-engineered 20000 lb electric winch with full ATEX Zone 2 certification. The winch featured a specialized closed-loop VFD control for ultra-fine speed adjustments (down to 0.1 m/min) and an integrated remote diagnostic system. The client reported a 15% reduction in project lift duration due to the winch's precision and reliability, coupled with enhanced safety for personnel operating in the sensitive environment.

Case Study 2: Hydropower Dam Gate Operations in Southeast Asia

For a critical hydropower facility, the existing gate lifting mechanisms were aging and prone to failures. We designed and installed a bespoke 20000 lb electric winch system, featuring a Galvanized Steel Wire Rope Winch Drum and marine-grade protective coatings, specifically for operating large spillway gates. The system included redundant power supplies and an advanced PLC with real-time feedback on gate position and load. The solution significantly improved operational uptime, with zero unscheduled maintenance events in the first three years, and provided unparalleled control over water flow management, critical for both power generation and flood control.

Customer Feedback

Across these and numerous other projects, customer feedback consistently highlights the reliability, robust construction, and advanced safety features of our winches. Clients commend the precision of control, ease of maintenance, and the comprehensive support provided, confirming our commitment to exceeding expectations. For instance, a construction manager noted, "The winch’s variable speed control allowed us to perfectly align heavy steel beams, drastically cutting down on assembly time and improving site safety."

Figure 5: Winch in action during a complex industrial lifting task.

Ensuring Trust and Reliability: FAQ, Support, and Warranty

Frequently Asked Questions (FAQ)

-

Q: What is the typical lead time for a 20000 lb electric winch?

A: Standard configurations typically have a lead time of 8-12 weeks. Highly customized solutions, depending on complexity and specific component sourcing, may range from 16-24 weeks. We provide detailed project timelines upon order confirmation.

-

Q: What kind of maintenance is required for these heavy-duty winches?

A: Regular maintenance includes daily visual inspections, weekly lubrication of wire rope and moving parts, quarterly inspection of brakes and electrical connections, and annual comprehensive service checks (e.g., gearbox oil change, motor brush inspection). A detailed maintenance schedule is provided with each unit.

-

Q: Are your winches compatible with existing plant control systems?

A: Yes, our advanced control systems are designed for seamless integration with most industrial PLC, DCS, and SCADA systems. We offer custom programming and communication protocols (e.g., Modbus, Profinet, Ethernet/IP) to ensure compatibility.

-

Q: How does a 20000 lb electric winch differ significantly from a 2 ton electric winch?

A: The primary difference is capacity (20,000 lbs vs. 4,000 lbs). A 20000 lb electric winch is built for much heavier, continuous industrial loads, featuring larger motors, stronger gearboxes, more robust braking systems, and often advanced control capabilities (VFD, PLC) and higher duty cycle ratings (FEM 2m/M5, M6). A 2 ton electric winch is typically for lighter industrial or commercial applications with less demanding duty cycles.

Lead Time & Fulfillment

Our commitment to efficient project execution ensures timely delivery. Standard units typically ship within 8-12 weeks, while custom designs are quoted with specific lead times after detailed engineering review. We manage logistics globally, ensuring secure and efficient freight to your site. Each winch undergoes rigorous factory acceptance testing (FAT) before dispatch.

Warranty Commitments

All our 20000 lb electric winch units come with a comprehensive 2-year warranty covering manufacturing defects and component failures under normal operating conditions. Extended warranty options for up to 5 years are available. Our warranty reflects our confidence in the quality and durability of our products, providing peace of mind for your investment.

Customer Support and After-Sales Service

Our dedication extends beyond delivery. We offer extensive after-sales support including:

- Technical Assistance: 24/7 remote and on-site technical support by experienced engineers.

- Spare Parts Management: Comprehensive inventory of genuine spare parts to minimize downtime.

- Training Programs: Operator and maintenance personnel training, both at our facility and on-site.

- Preventative Maintenance Contracts: Tailored service agreements to ensure peak performance and extend asset life.

Figure 6: A team of engineers providing technical consultation.

Conclusion

The 20000 lb electric winch is more than just a piece of equipment; it's a strategic asset for heavy industries, embodying precision, power, and unparalleled reliability. From its meticulously engineered manufacturing process, incorporating high-grade materials and rigorous testing, to its deployment in the most demanding application scenarios across petrochemical, metallurgy, marine, and construction sectors, this winch class consistently delivers superior performance.

By focusing on advanced technical specifications, embracing industry trends like automation and energy efficiency, and offering robust customization and comprehensive after-sales support, these winches are designed to optimize operational workflows, enhance safety, and provide a significant return on investment. For B2B decision-makers and engineers, selecting a high-quality 20000 lb electric winch represents a commitment to operational excellence and long-term asset value in the challenging landscape of industrial material handling.

References

- ISO 9001: Quality management systems – Requirements. International Organization for Standardization.

- ANSI B30.7-2015: Winches (Standards for Overhead Hoists and Cranes). American Society of Mechanical Engineers.

- European Directive 2014/34/EU (ATEX): Equipment and protective systems intended for use in potentially explosive atmospheres. European Union.

- FEM 1.001: Rules for the Design of Hoisting Appliances. Federation Europeenne de la Manutention.

- NEMA MG 1-2016: Motors and Generators. National Electrical Manufacturers Association.

- Wire Rope Users' Manual. Wire Rope Technical Board.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025