Need a Grooved Drum with High Traction and Long Life?

If you run cranes or winches for a living, you already know the quiet hero is the grooved drum. It decides whether your wire rope spools cleanly—or birds’ nests by lunch. Over the past two years, demand has shifted toward split LBS sleeves that retrofit onto legacy smooth or spiral drums. To be honest, it’s a very practical way to stretch capex without compromising safety.

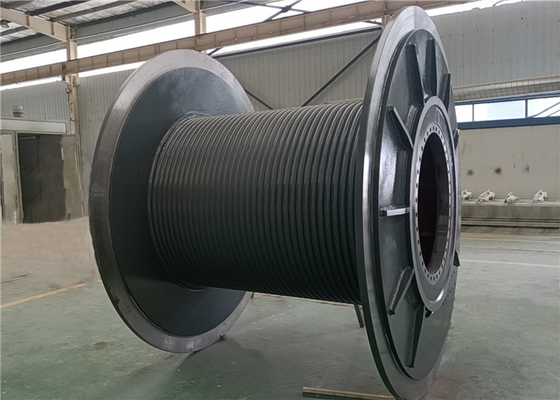

The product I’ve been watching closely is the “Grooved Drum Skin Drum Winch Cover Grooved Sleeves For Smooth Drum,” manufactured in Shijiazhuang, Hebei (NO.688 Zhongshan Road, Qiaoxi district). It’s available as a split sleeve (retrofit) or as an integrated drum with the LBS pattern machined directly. Many customers say the swap-out model saves downtime when rope sizes change mid-contract—surprisingly often in rental fleets.

Why the shift now?

Three things: variable rope diameters across projects, stricter spooling standards offshore, and a renewed obsession with wire-rope life cycle cost. A well-made grooved drum reduces crossovers and crushing, which means fewer rope replacements and calmer operators. I guess nobody misses the sound of scrubbing a kinked rope through a sheave.

Product snapshot (real-world values)

| Type | Split LBS rope groove sleeve; Integrated LBS grooved drum |

| Materials | 45# steel / Q235 / 42CrMo; optional nylon sleeves |

| Rope diameter range | ≈ 8–50 mm (others on request) |

| Axle/drum length | ≈ 200–3000 mm (custom) |

| Groove pattern | LBS: inclined + parallel groove sections for layered spooling |

| Surface | Phosphate/painted; hardness target ≈ HRC 45–55 (steel) |

| Commercials | FOB US $0.5–9,999/pc; MOQ 100; Supply ≈ 10,000 pcs/month |

| Origin | Shijiazhuang, Hebei, China |

How it’s made (and why it matters)

• Materials: steel or nylon selected per duty class and rope type (EN 12385 compatible).

• Machining: CNC turning and milling of the LBS profile; groove profile tolerance ≈ ±0.1 mm in practice.

• Heat treatment (steel): to achieve wear resistance; then finishing and deburring.

• NDT: MT/UT on welds and high-stress areas; surface runout target ≤ 0.15 mm.

• Balance: ISO 1940-1 Grade G6.3 typical on integrated grooved drum assemblies.

• Installation (split sleeves): bolt-on over smooth or spiral drums; shimmed to maintain pitch accuracy.

• QC: traceability, hardness checks, coating thickness, and rope spooling test with fleet angle 0.5–1.5°.

Where it’s used

Offshore and deck winches (DNV governed), port cranes, mining hoists, construction winches, tower cranes, even wind installation tuggers. In theater rigging and utilities, nylon sleeves soften contact where rope cosmetics matter.

Vendor snapshot (what buyers compare)

| Vendor | Design method | Lead time | Compliance | Customization |

|---|---|---|---|---|

| LBS (Hebei) | LBS pattern, CNC, sleeve or integrated | Around 3–6 weeks | ISO 9001; aligns with EN 12385, ISO 1940-1 | High; rope/diameter/face width |

| Importer A | Generic spiral grooves | 8–10 weeks | Varies; paperwork-heavy | Medium |

| Local Shop B | Custom, mixed methods | 1–4 weeks | Depends on job; limited documentation | High but variable QA |

Field notes and results

A port crane operator switched from a worn spiral drum to split LBS sleeves on a 26 mm rope. After six months, rope discard frequency dropped by roughly 25–30% and operators reported cleaner third-layer spooling. Another offshore tug winch used nylon sleeves to tame corrosion and saw steadier back-tension during storm holds—small changes, big relief.

Standards, testing, and service life

Typical shop tests include groove gauge checks, hardness, coating thickness, balance per ISO 1940-1, and a spooling test using EN 12385 wire rope. For offshore cranes, many buyers reference DNV-ST-0378; oil & gas buyers often mirror API Spec 8C. Real-world life depends on fleet angle, back-tension, and rope quality; under good practice, sleeves often run multiple rope lives before refurbishment. Certifications such as ISO 9001 are commonly requested.

Bottom line: a well-executed grooved drum or split LBS sleeve is a cost-control tool disguised as a cylinder. If you’re planning a rope size change later this year, the retrofit route is, actually, the safe bet.

References

- EN 12385 Steel wire ropes — Safety.

- ISO 1940-1 Mechanical vibration — Balance quality requirements for rotors.

- DNV-ST-0378 Standard for offshore and platform lifting appliances.

- API Spec 8C Drilling and Production Hoisting Equipment.

- ISO 4301/4306 Cranes — Classification and terminology.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025