Mechanical Drum Winch – Heavy-Duty, High Torque, Reliable

Mechanical Drum Winch is a key solution in the manufacturing industry, specifically within General equipment manufacturing industry and Manufacturing of lifting and transportation equipment. This article explores how Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Mechanical Drum Winch Overview

- Benefits & Use Cases of Mechanical Drum Winch in Manufacturing of lifting and transportation equipment

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Mechanical Drum Winch from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

Mechanical Drum Winch Overview

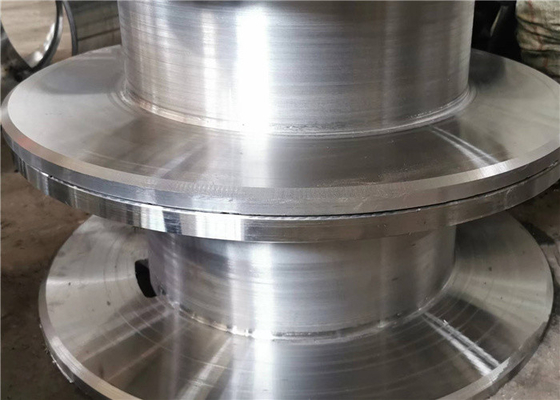

A Mechanical Drum Winch is a power-transmission assembly that winds and unwinds wire rope on a cylindrical drum to lift, pull, or position heavy loads. In the General equipment manufacturing industry, especially the Manufacturing of lifting and transportation equipment, drum winches serve as the backbone of cranes, hoists, deck machinery, and material handling lines. The drum—often precision-grooved—ensures controlled spooling, consistent line pull, and maximized rope life.

Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. engineers and manufactures drums in robust materials such as Q355B steel, with optional Lebus-style multi-layer grooving for even winding across multiple rope layers. Configurations include single- and double-drum options, clutched or free-spooling auxiliaries, and compatibility with electric or hydraulic drives through gearboxes and brakes. Typical specifications can be tailored: line pull ratings from light duty to heavy 10T+ applications, drum diameters and face widths based on rope size and capacity, and surface treatments for corrosion resistance in marine or outdoor environments. Precision machining and concentricity control help minimize vibration and wear, improving reliability on high-duty cycles common in industrial operations.

Backed by strict process control and application engineering, Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. is a reliable manufacturing partner for OEMs and project contractors requiring dependable winch drums and complete winching solutions.

Benefits & Use Cases of Mechanical Drum Winch in Manufacturing of lifting and transportation equipment

In lifting and transportation equipment, a Mechanical Drum Winch is integral to mobile cranes, gantry cranes, tower cranes, bridge maintenance units, shipboard and offshore deck equipment, mining and tunneling hoists, pipeline handling, and factory logistics lines. Double-drum configurations enable synchronized lifting or dual-function operations (main/auxiliary), while grooved drums ensure stable multi-layer spooling during long pulls and variable angles—critical for safety and uptime in field conditions.

- Even spooling and reduced rope crush thanks to precision grooving, supporting longer rope service life.

- Q355B steel construction and robust weldments for high load-bearing capacity and fatigue resistance.

- Customizable geometry (drum diameter/length, flange size, groove pitch) to match rope specs and duty cycles.

- Integration with brakes, clutches, encoders, and load monitoring to meet modern safety and control requirements.

With deep experience across construction, marine, and industrial projects, Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. helps B2B decision makers specify the right drum design, material, surface finish, and accessory package needed for mission-critical lifting equipment—reducing integration risk and accelerating commissioning.

Cost, Maintenance & User Experience

Total cost of ownership for a Mechanical Drum Winch is driven by rope life, component durability, maintenance intervals, and downtime costs. Precision-grooved drums help reduce localized rope wear and crushing, while proper drum sizing limits bending fatigue—both lowering rope replacement frequency. Rugged materials, accurate concentricity, and balanced fabrication minimize vibration and bearing stress, which translates into fewer unplanned stoppages and a better ROI over multi-year service windows.

- Planned maintenance is straightforward: periodic rope inspection, lubrication, groove cleaning, and fastener torque checks.

- Spare parts support and clear documentation from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. streamline overhaul cycles.

- Operators benefit from predictable line lay and stable tension, improving safety and productivity on long lifts and pulls.

Feedback from industrial users highlights easier rope handling and fewer re-spooling interventions after upgrading to grooved drums. For procurement teams looking to buy mechanical drum winch solutions that balance price, performance, and lifecycle costs, Junzhong’s engineered approach provides measurable operational value.

Sustainability & Market Trends in manufacturing

Sustainability in lifting equipment increasingly focuses on longer-lasting components, energy-efficient operation, and responsible material use. By promoting even spooling and reducing rope waste, a well-designed Mechanical Drum Winch contributes to fewer consumables and less downtime, which in turn lowers energy and emissions per lifted ton. The recyclability of steel drums and the possibility of refurbishment or re-grooving extend product life and support circular economy practices in heavy industry.

Market trends also point to digital integration—sensors for line tension, load count, and drum speed feed into maintenance dashboards, enabling predictive servicing and safer operations. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. aligns with these trends by offering customizable drums ready for instrumentation, corrosion-resistant coatings for harsh environments, and engineering collaboration from concept to commissioning. This forward-thinking approach helps OEMs and end users meet evolving safety guidelines and sustainability targets without compromising lifting performance.

Conclusion on Mechanical Drum Winch from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

For B2B decision makers in the General equipment manufacturing industry and the Manufacturing of lifting and transportation equipment, the Mechanical Drum Winch remains a foundational asset—delivering controlled spooling, dependable load handling, and long-term reliability. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. combines robust materials, precise grooving, and application engineering to reduce lifecycle costs and elevate operational safety.

- Contact us: email: lbswinch@lebus.com.cn

- Visit our website: https://www.lbswinch.com

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025