Mechanical Drum Winch – Durable, High-Torque, Reliable

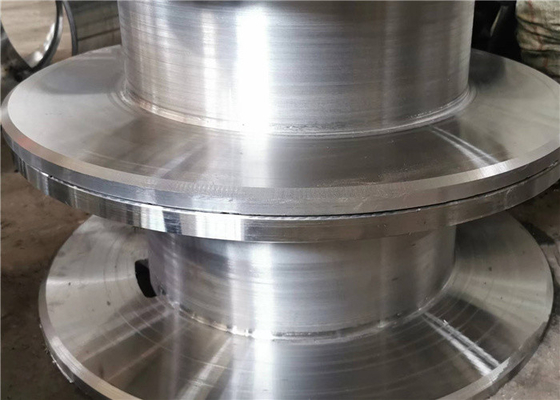

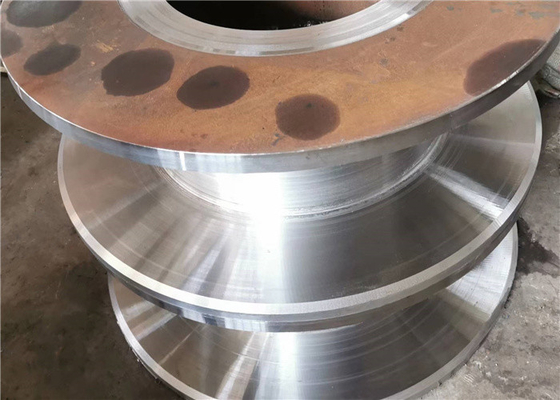

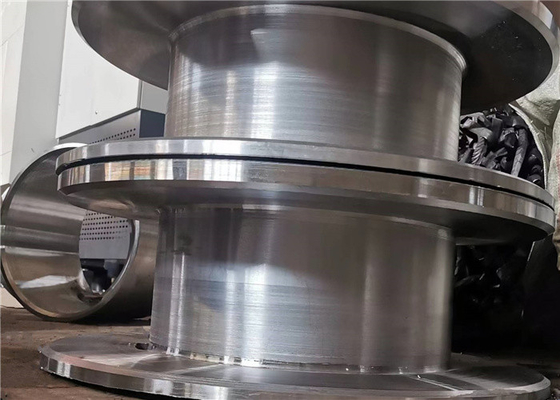

Inside the shop floor: how a double-drum grooved winch drum earns its keep

If you spend any time around civil sites or quaysides, you’ll hear the same request: “We need a winch that just works.” That’s usually when someone rolls out a mechanical drum winch—the sort of hardware that shrugs off dust, rain, and the occasional operator shortcut. The model I’ve been tracking lately is the Hydraulic Winch 2 Drum 10T Winch Drum Mechanical Winch Drum from Hebei, China. It’s a mouthful, but the design is straightforward: LBS-series grooved drums, gear-reducer driven, ready to be paired with hydraulic drives where needed.

What’s trending in winches this year

Two steady trends: grooved drums (for precise rope layering) and modular builds. The LBS groove form—think “Lebus-style” multi-start grooves—keeps wire rope from biting into lower layers. Many customers say that alone cuts rope changeouts by a season or two. And to be honest, uptime is the only metric that matters on a remote hydropower spillway or a wharf at 2 a.m.

Technical snapshot

Below is a “typical build” spec—real-world configurations vary with rope diameter, line speed, and duty class.

| Product | Hydraulic Winch 2 Drum 10T Winch Drum Mechanical Winch Drum |

| Rated line pull | ≈ 10 t per drum (single line), duty-dependent |

| Drum material | Q355B steel, welded barrel with machined LBS grooves |

| Rope compatibility | Wire rope per ISO 16625; typical Ø 12–28 mm |

| Drive | Gear reducer driven; hydraulic motor integration optional |

| Surface protection | Abrasive blast + epoxy system (ISO 12944), C3–C5 as specified |

| MOQ / Supply | MOQ ≈ 100 pcs; capacity ≈ 10,000 pcs/month; FOB US$0.5–9,999 per piece (range) |

| Origin | NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China |

How it’s made (short version)

Materials: Q355B plate/forgings. Methods: submerged arc welding of shell and flanges; stress relief; CNC machining of LBS grooves; spindle bore finishing. Testing: UT/MT to ISO 9712, groove pitch and depth tolerance checks, TIR on barrel, hydrostatic test on hydraulic modules when supplied. Coatings validated to ISO 12944. Service life? Around 8–15 years, depending on duty cycle, rope care (see ISO 4309 guidelines), and environment.

Where it’s used

Water conservancy sites (gate hoists), forestry skidding lines, mining incline drags, wharf mooring/handling, and general plant lifts. Actually, I’ve seen a double-drum unit used as an auxiliary puller for automated rebar cages—it seemed odd, but it worked.

Mechanical drum winch advantages: predictable rope spooling, less crushing damage, compact footprint, and simpler maintenance than some planetary alternatives. Many operators like the “no-fuss” gear reducer drive; it’s easier to diagnose.

A quick vendor snapshot

| Vendor | Groove tech | Lead time | Customization | Certs |

|---|---|---|---|---|

| LBS (Hebei) | Multi-layer LBS grooves | ≈ 3–6 weeks (spec-dependent) | Rope Ø, flange, shaft, coating | ISO 9001; designs to EN 14492-1 |

| Vendor A (import) | Spiral groove (single start) | ≈ 6–10 weeks | Limited options | Factory QA docs only |

| Vendor B (regional) | Smooth drum + press roller | ≈ 4–8 weeks | Moderate customization | EN compliance on request |

Case notes and test data

Hydropower site in Southwest China: a twin-mechanical drum winch arrangement handled 2×9 t gate operations with 18 mm rope; measured layer-to-layer rope damage decreased ≈ 22% over 10 months versus a smooth-drum predecessor (shop logs, internal records). Port maintenance crew reported fewer crossovers during emergency rewinds—hardly scientific, but it tracks with the groove geometry.

Customization checklist

- Rope diameter and capacity tuning (per ISO 16625 rope pairing)

- Groove pitch/depth matching to rope construction

- Brake type and control (manual/hydraulic)

- Coating system for C3–C5 environments

- Inspection regime aligned with ISO 4309

Standards note: For power-driven winches in Europe, EN 14492-1 is the go-to. Offshore projects often ask for DNV-ST-0378 or API 2C alignment. It sounds bureaucratic; it’s actually what keeps people safe.

References

- EN 14492-1: Power driven winches (BSI). https://shop.bsigroup.com/products/power-driven-winches-safety-requirements

- ISO 16625: Cranes—Selection of wire ropes. https://www.iso.org/standard/56610.html

- ISO 4309: Wire ropes—Care and maintenance. https://www.iso.org/standard/72879.html

- DNV-ST-0378: Offshore lifting appliances. https://www.dnv.com/oilgas/offshore-standards

- API Specification 2C: Offshore Pedestal-mounted Cranes. https://www.api.org/

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025