Large Drum Winch — High-Capacity, 240V Electric Power

Large Drum Winch is a key solution in the manufacturing industry, specifically within Special Equipment Manufacturing Industry and Manufacturing of lifting machinery. This article explores how Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Large Drum Winch Overview

- Benefits & Use Cases of Large Drum Winch in Manufacturing of lifting machinery

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Large Drum Winch from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

Large Drum Winch Overview

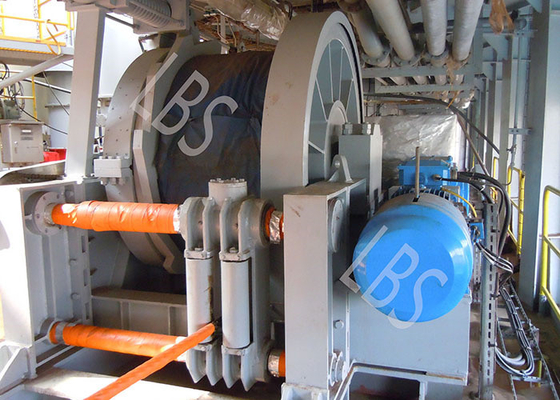

A Large Drum Winch is a heavy-duty, electric-powered lifting and pulling solution engineered for long rope storage and high line-pull tasks. In the Special Equipment Manufacturing Industry, it is indispensable for crane builders, shipyards, steel mills, cement plants, and infrastructure projects that require controlled, multi-layer spooling, reliable braking, and precise positioning. Typically, configurations include line pulls up to approximately 350 kN (about 35 t), rope diameters from 8–56 mm, and drum capacities extending to thousands of meters—paired with level-wind spooling devices to ensure even winding and extend wire rope service life.

Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. designs and builds large-capacity electric drum winches with robust gearboxes, fail-safe electromagnetic or hydraulic brakes, and optional variable frequency drives (VFDs) for smooth starts and stops. Enclosures and components can be specified for harsh environments, with IP55–IP65 protection, marine coatings, and low-temperature packages. While plant-scale systems commonly use three-phase power (380–480V), the company also supports application-specific solutions alongside complementary ranges such as an electric winch 240v or a small electric winch 240v for lighter-duty maintenance tasks. This breadth ensures fit-for-purpose performance across manufacturing of lifting machinery.

Benefits & Use Cases of Large Drum Winch in Manufacturing of lifting machinery

For crane and hoist manufacturers, a Large Drum Winch forms the core of trolley, boom, and main hoist systems where long lifting heights and precise load control are essential. In shipbuilding and heavy fabrication, these winches handle block positioning, slipway launches, and structural pulling. In steel and cement plants, they support ladle handling, mill maintenance, and conveyor take-up systems—where a large drum and level-wind spooling device maintain consistent tension, reduce rope damage, and enhance safety.

- Level-wind spooling with Lebus-style grooving for multi-layer, even winding and extended rope life.

- High-torque gear reduction and fail-safe braking for precise, controlled starts and stops.

- VFD-ready drives for smooth acceleration, load sharing, and synchronized multi-winch operations.

- Customizable drums, rope guides, and protective enclosures for marine, mining, and plant environments.

With decades of engineering and field experience, Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. advises OEMs and EPCs on specification, selection, and integration—reducing commissioning time and ensuring compliance with project standards. From factory acceptance tests to on-site support, the company is structured to meet B2B timelines and safety requirements in the manufacturing of lifting machinery.

Cost, Maintenance & User Experience

Total cost of ownership for a Large Drum Winch is driven by uptime, rope life, and energy efficiency. Robust gear trains, sealed bearings, and optimized grooving reduce wear and maintenance frequency. Level-wind spooling significantly lowers wire rope replacement costs by distributing load evenly across layers. When paired with VFDs, operators gain smoother control, reduced mechanical shock, and lower peak currents—supporting both productivity and motor longevity. For B2B decision makers, these attributes translate into shorter payback periods and dependable ROI across multi-year duty cycles.

- Service-friendly layout with accessible lubrication points and inspection covers.

- Optional condition monitoring (load, temperature, vibration) for predictive maintenance.

- Operator-friendly controls: local/remote panels, soft-start, emergency stops, and interlocks.

Customers in the Special Equipment Manufacturing Industry value reliable braking, consistent spooling, and clear documentation for audits and compliance. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. supports lifecycle performance with spare parts availability, commissioning assistance, and training—helping teams maintain safe, repeatable operations in demanding environments.

Sustainability & Market Trends in manufacturing

Electrification, digitalization, and safer workplaces are shaping the future of lifting machinery. Modern Large Drum Winch systems increasingly incorporate energy-efficient motors, VFDs for optimized power use, and regenerative braking where applicable. Compliance with international standards and local regulations (e.g., CE, GB/T, and relevant safety norms) supports risk reduction and sustainable operations. Smart sensors enable data-driven maintenance, minimizing unplanned downtime and waste.

Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. aligns with these trends through configurable, electric solutions that reduce hydraulic fluid use, durable coatings with lower environmental impact, and designs that extend component lifecycles. For facilities with varied power infrastructures, the portfolio includes solutions adaptable to regional voltages—including three-phase industrial power and auxiliary ranges like an electric winch 240v or a small electric winch 240v for lighter tasks—helping manufacturers balance efficiency, sustainability, and performance across their lifting fleets.

Conclusion on Large Drum Winch from Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd.

Purpose-built for heavy-duty applications, the Large Drum Winch delivers controlled lifting, long rope capacity, and dependable performance—making it a cornerstone solution for the Special Equipment Manufacturing Industry and the manufacturing of lifting machinery. Shijiazhuang Junzhong Machinery Manufactruing Co., Ltd. combines engineering expertise with configurable features and lifecycle support to help B2B teams reduce risk and maximize uptime.

- Contact us: email: lbswinch@lebus.com.cn

- Visit our website: https://www.lbswinch.com

- Explore the product page: Large Drum Winch with spooling device

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025