Large Drum Winch – High Capacity, 240V Electric, Durable

Field Notes: the Electric Single Drum Winch with Spooling Device

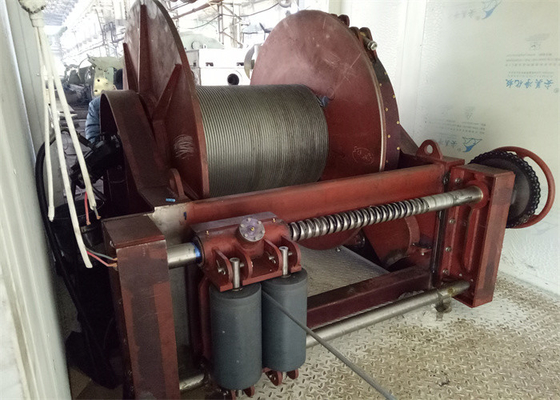

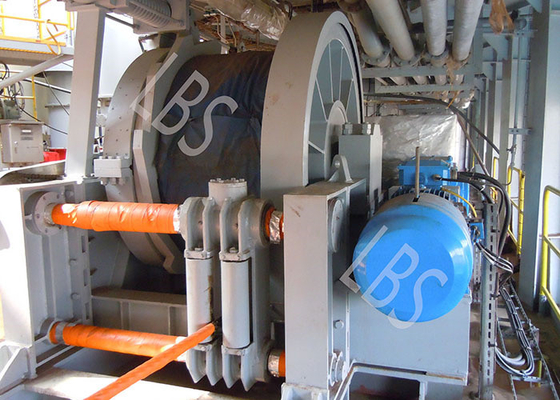

On a recent visit to NO.688 Zhongshan Road, Qiaoxi District, Shijiazhuang, Hebei, China, I spent a morning watching an large drum winch go through load testing. The model on the floor—Electric Single Drum Winch Large Capacity Drum Winch With Spooling Device—looked unassuming, but the moment the rope bit into the LBS-style grooved drum, you could feel the engineering choices in your bones.

What’s trending—and why it matters

Across construction, hydropower sites, and ports, demand for large drum winch systems with precise spooling is up. Why? Higher line-pull with safer rope management, integration with VFD controls, and smarter braking. Many buyers tell me they want fewer rope replacements and quicker rig-up. Honestly, that’s where grooved drums and active spooling devices earn their keep.

Core specs at a glance

Below is a typical configuration; real-world use may vary by duty cycle and rope selection.

| Parameter | Typical Value (≈) |

|---|---|

| Rated line pull | 10–35 t |

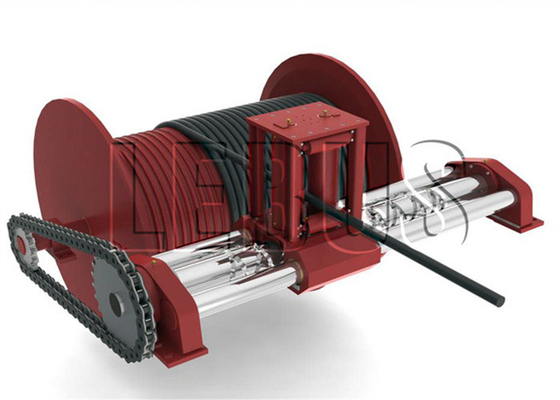

| Drum diameter / width | Ø450–900 mm / 600–1,600 mm |

| Rope diameter | 18–42 mm (1770–1960 MPa class) |

| Rope capacity | 300–1,200 m |

| Line speed | 6–22 m/min (VFD optional) |

| Drive / power | Electric, 22–110 kW, 380–690 V |

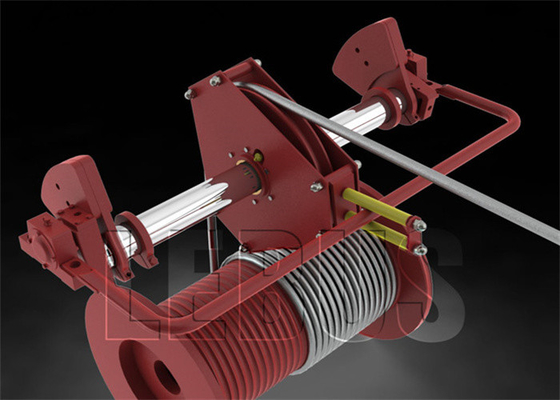

| Spooling device | Mechanical or hydraulic level-wind |

| Protection / duty | IP54–IP65; FEM 2m–3m, ISO 4301 A5–A7 |

How it’s built: materials, methods, testing

- Drum and frame: Q345B/ASTM A572 steel, LBS-style helical groove to stabilize winding.

- Gearing: case-hardened alloy steel, 58–62 HRC surface; safety brake with dual-circuit options.

- Process flow: plate cutting → stress-relief welding → machining → groove cutting → assembly → load testing.

- Testing standards referenced: EN 14492-1, ASME B30.7, ISO 4301 series, GB/T 10055 (where applicable).

- Test data (factory example): 125% static overload hold; no-load noise ≈78–83 dB(A); insulation ≥F class; paint DFT ≈120–160 μm.

- Service life: drum/frame 10–15 years with maintenance; wire rope replacement intervals depend on cycles and sheave condition.

Where it works

Construction lifts, hydropower gates, mine incline haulage, barge positioning, forestry skidding, docks—and, surprisingly, oil mills that need synchronized pulling. A large drum winch with level-wind cuts rope crossovers, which is exactly what many customers mention in feedback: fewer crushed strands and smoother payout.

Vendor snapshot (buyer’s quick read)

| Vendor | Strengths | Watch-outs |

|---|---|---|

| Factory (Hebei) | Grooved drums, custom level-wind, short lead times, CE/ISO 9001 (where applicable) | MOQ around 100 units; engineering sign-off needed |

| OEM A | High-duty offshore options, DNV review available | Premium pricing, longer FAT slots |

| Importer B | Stock units, fast shipping | Limited customization; generic spooling devices |

Customization and buying notes

Options include rope type (galvanized compacted, plastic-impregnated), ATEX zones, marine coatings C4–C5M, VFD with torque control, and radio/PLC integration. For this large drum winch, FOB pricing is quoted as US $0.5–9,999 per piece (yes, that’s a broad bracket), MOQ ≈100 units, supply ≈10,000 units/month. Always ask for a rope-drum pairing calculation and a spooling demo video.

Two quick case notes

- Oil mill retrofit: 35 t large drum winch with hydraulic level-wind; rope life improved ≈30% after groove optimization and better fleet angle control.

- Floodgate duty: 10 t unit, VFD + encoder; creep speed allowed operators to “feather” the gate, reducing shock loads and brake wear.

Citations

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025