Grooved Drum Winch | High Pull, Anti-Slip, Dual Drum Option

Inside the Grooved Drum Revolution: Why cranes are switching fast

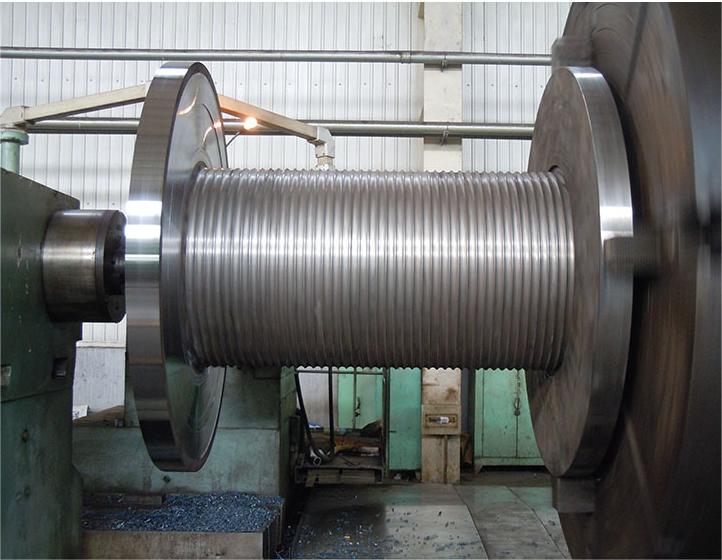

A Grooved Drum Winch looks like a simple cylinder until you watch how it lays rope—precisely, layer after layer. In fact, that’s where the story gets interesting. The “double folded” groove pattern (many engineers call it the Lebus concept) keeps rope tracking tidy even at high layers, which is why ports, wind farms, and heavy-lift yards are quietly standardizing on it.

Trends? Multi-layer spooling is back in demand as equipment footprints shrink but lifting heights grow. Energy operators want predictable rope life; construction wants fewer callouts. And—surprisingly—buyers now ask more about sleeves and repairability than about the hoist frame itself.

The product in one breath

Product: Design According To The Diagram Steel Wire Rope Drum With A Shaft Accessories For Crane. Origin: NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China. It’s a welded flat drum plus a replaceable grooved sleeve—so if the groove wears or specs change, swap the sleeve, not the whole drum. Price guidance: FOB ≈ US $0.5–9,999 per piece, MOQ 100; supply ≈ 10,000 pcs/month (real-world use may vary by spec and coating). To be honest, that replaceable sleeve is where the lifecycle savings hide.

How it’s built (and tested)

• Materials: shell in S355JR or Q345B; shafts in 42CrMo (quenched/tempered).

• Welding: AWS D1.1 / GB standards; NDT via UT + MT on critical seams.

• Groove machining: CNC-milled “double line” geometry; pitch tolerance ≈ ±0.05 mm; surface Ra ≈ 3.2 μm.

• Heat/finish: optional induction-hardened sleeve; shot-blast Sa 2.5; epoxy system ≈ 80 μm primer + 120 μm topcoat.

• Balance: ISO 1940 G6.3 (typical).

• Rope compliance: ISO 4309 maintenance guidance; groove matched to rope Ø and construction.

• Service life: often 8–12 years on sleeves under normal duty; heavy multi-layer cycles shorten it—predictably.

Indicative specifications

| Drum Ø range | 300–1,800 mm (custom up to 2,800 mm) |

| Rope Ø | 6–64 mm, matched groove radius |

| Layers | 3–18 layers (≈, application-dependent) |

| Groove pitch | Rope Ø × 0.98–1.02 (tuned by rope build) |

| Sleeve | Split or one-piece; replaceable |

| Surface hardness | Up to ≈ HRC 45 (induction-hardened) |

Where it’s used (and why it matters)

You’ll meet the Grooved Drum Winch on mobile/tower cranes, piling rigs, offshore deck machinery, mining hoists, even stage lifts (quiet spool-in counts backstage). The double-line groove reduces cross-layer bite, so rope strands don’t crush each other on the 7th…8th layer. Many customers say rope inspections are calmer now—less bird-cage drama.

Vendor snapshot: how options compare

| Vendor | Groove concept | Sleeve replaceable | Lead time | Certs | Indicative cost |

|---|---|---|---|---|---|

| LBS (this model) | Double folded (multi-layer) | Yes (split or one-piece) | ≈ 4–8 weeks | ISO 9001, material traceability | Mid, lifecycle-low |

| European Brand A | Proprietary multi-layer | Yes | ≈ 8–14 weeks | ISO 9001/14001 | High |

| Local Fabricator | Single or random groove | Rarely | ≈ 2–6 weeks | Varies | Low, lifecycle-uncertain |

Customization, documentation, compliance

This Grooved Drum Winch is “design according to the diagram,” meaning the groove, shaft journal, keyway, and flange geometry follow your GA drawing. Options: split sleeves for field replacement, QPQ/nitriding, stainless overlays for marine, and third-party inspection (BV, DNV, ABS on request). Documentation pack typically includes MTCs, NDT reports, balance sheet, paint DFT logs.

Field results (two quick cases)

Port retrofit, SE Asia: 7-layer container crane hoist. After swapping to double-line sleeve, rope discard rate dropped ≈ 23%, and inspection intervals stretched from 250 h to ≈ 320 h. Operators noted less “snap-back” at payout.

Onshore wind install, North China: Mobile crane main hoist. Noise at the drum reduced ≈ 2.5 dB(A), and cross-groove impressions on layer 6 were “barely visible” in borescope photos. Crew feedback: “spools neat even in gusts.”

If you need a Grooved Drum Winch fast—or you’re chasing rope life rather than headline pull—this design is, I guess, the practical choice. Factory site: NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China. Support teams are used to OEM/ODM handoffs.

Authoritative citations

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025