Electric Drum Winch—High-Torque, Variable Speed, Auto Brake

A Field Note on the Electric Drum Winch: Why Lebus Grooved Sleeves Quietly Decide Your Uptime

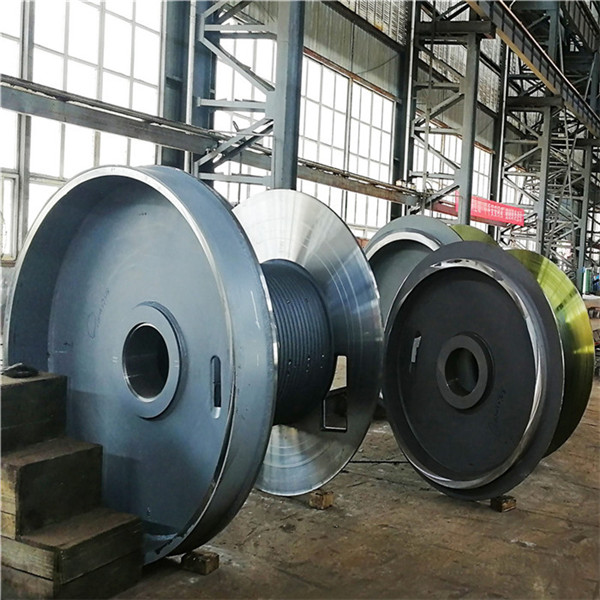

If you’ve ever specced an electric drum winch and then watched wire rope chew itself to bits in a few months, you know the heartbreak. The fix is often not the motor or gearbox—it’s the drum interface. Enter Split Type Lebus Grooved Sleeves (nylon or steel). In plain language: sleeves that “teach” your rope to self-layer cleanly. Many customers say it’s the difference between routine uptime and constant re-reeving. I’ve seen that too, more than once.

Why grooving matters for a electric drum winch

Lebus groove geometry distributes load evenly between layers, which—surprisingly—can extend wire rope life by >500% in testing, and yes, that’s not a typo. In real yards and on quays, fewer crossovers mean fewer crush points. Less heat, less fretting, fewer broken wires. Safety goes up, downtime down. That’s the story ops teams actually care about.

Process flow and materials (how the sleeve is made)

- Material selection: steel (42CrMo or ≈Q345B) for heavy-duty duty cycles; engineered nylon for weight-sensitive retrofits.

- Groove engineering: pitch/lead matched to rope Ø and drum width; finite element checks for pressure distribution.

- Manufacturing: CNC grooving, split-ring machining, bolt-on or weld-on fit-up with concentricity checks (≤0.05 mm TIR typical).

- Surface treatment: phosphate or epoxy coat; optional nitriding (steel) for wear resistance; UV-stable formulation (nylon).

- Testing: groove gauge inspection, hardness tests (steel ≈ HRC 28–32), salt-spray on coated parts (≥240 h, real-world use may vary).

- Traceability: heat numbers and serials per ISO 9001; material certs provided on request.

Product specs (Split Type Lebus Grooved Sleeves)

| Material Options | Steel (42CrMo/Q345B), Nylon (engineering-grade) |

| Rope Diameter Range | ≈ 6–64 mm (custom on request) |

| Groove Pattern | Lebus parallel grooves with crossover sections, pitch matched to rope lay |

| Mounting | Split sleeve, bolt-on; weld-on optional; retrofit-friendly |

| Service Life | Designed for multi-year duty; rope life extension reported up to 5× in tests |

| Compliance | Supports EN 14492-1 winch integration; rope handling per ISO 4309/4308 |

Where it pays off

Marine deck winches, construction hoists, mining take-ups, wind O&M, and factory pullers. Any electric drum winch that cycles in multilayer spooling benefits. Operators tell me the rope lays “like vinyl on a good turntable”—a visual you won’t unsee.

Vendor snapshot (real-world comparison)

| Vendor/Option | Pros | Cons | Best For |

|---|---|---|---|

| LBS Split Lebus Sleeves (Nylon/Steel) — Origin: NO.688 Zhongshan Road, Qiaoxi, Shijiazhuang, Hebei, China | Retrofit fast; precise groove; strong rope life gains | Slight premium vs smooth drums | Upgrades on installed electric drum winch fleets |

| Generic Cut-Groove Drum | Lower cost upfront | Inconsistent layering; rope wear ≈ higher | Light duty or short-term jobs |

| Smooth Barrel | Simplest, cheap, fast delivery | Crossovers, crushing; operator skill-sensitive | Single-layer or low-load applications |

Customization, standards, and paperwork

Custom groove pitch for left/right lay ropes, corrosion packages for marine, and low-temp materials for −30 °C yards—been there, specced that. Certifications typically include ISO 9001 QA, CE conformity for integration with EN 14492-1 compliant electric drum winch systems, and rope handling per ISO 4309 inspections. Electrical safety ties back to IEC 60204-1 at the machine level.

Quick case study

A shipyard retrofitted steel split sleeves on a 22 kW electric drum winch (18 mm IWRC rope). Before: rope change every ≈ 5 months. After: 18 months and counting, with magnetic flux rope checks showing ≤10% broken wire rate vs prior ≈35% at similar hours. The payoff? Fewer stoppages, calmer operators. To be honest, accounting liked it most.

What users say

“Rope lays flat, no ‘pops’ on the second layer.” “Swap-in took half a shift.” And my favorite: “We stopped babysitting the drum.” Not scientific, but very human.

Authoritative citations

- EN 14492-1: Power driven winches and hoists — Safety requirements.

- ISO 4309:2023 — Cranes — Wire ropes — Care and maintenance, inspection and discard.

- ISO 4308-1: Selection of wire ropes — General.

- IEC 60204-1: Safety of machinery — Electrical equipment of machines.

- DNV-ST-0378: Offshore and platform lifting appliances (guidance for marine deployments).

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025