Electric Drum Winch | High-Torque, Compact, Double-Drum

Electric Drum Winch: what’s changing on the deck and in the yard

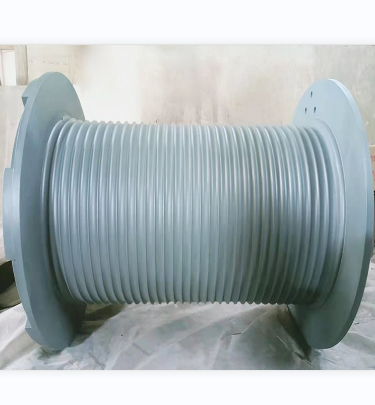

If you’re specifying an Electric Drum Winch, the drum itself is doing more of the hard work than most folks admit. To be honest, I’ve seen more uptime issues from poor drum geometry than from motors. That’s why the LBS grooved single fold-line drum caught my eye—practical, serviceable, and priced to land on tough job sites without drama.

Industry snapshot

Across construction, marine, and mining, operators are moving to compact, gear-reducer-driven drums matched to VFD-controlled motors. The headline trend? Consistent spooling under variable loads. In fact, grooved drums with precise pitch keep wire rope health in check, especially as duty cycles increase and safety audits get stricter. Many customers say they’re willing to pay a bit more for clean layering because it extends rope life and lowers downtime.

Product snapshot: LBS Grooved Drum (Single Fold-Line)

| Model | Made In China Winch Accessories Alloy Steel Single Fold Line Drum |

| Material | Alloy steel (quenched and tempered), optional surface nitriding ≈55–60 HRC |

| Groove type | Single fold-line (precise pitch for even spooling) |

| Wire rope range | ≈8–48 mm (real-world use may vary) |

| Drive pairing | Gear reducer-driven hoisting systems; VFD motor recommended |

| Finish | Anti-corrosion coating; marine epoxy optional |

| Certs (typical) | CE (Machinery Directive), ISO-based QC; designs to ASME B30.7/DNV where specified |

| MOQ / Supply | Min. 100 pcs; ≈10,000 pcs/month |

| FOB price | US $0.5–9,999 per piece (spec-dependent) |

| Origin | NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China |

Where a Electric Drum Winch drum earns its keep

- Construction lifts and formwork handling.

- Water conservancy gates, forestry skidders, mine hoists.

- Wharf/shipyard tuggers; factory automation as auxiliary take-up reels.

Advantages: predictable spooling (longer rope life), smoother torque transfer via reducer, and compact package. Surprisingly, you can hear the difference—less scraping when layers settle correctly.

How it’s made and verified

Materials: alloy steel forged/cast, normalized, then Q&T. Methods: CNC groove machining, runout control, dynamic balance. Optional nitriding for wear. Testing: NDT (MT/UT) on welds and shell; coating DFT checks; proof-load to ≈1.25× rated line pull; functional spooling tests with rope per ISO 4308-1 selection rules. Service life: ≈10–15 years with proper rope lubrication and IP-rated enclosures on the drive (IEC 60529). Industries: civil, mining, marine, energy, automated handling.

Real-world notes

- Hydro project winch retrofit: grooved drum cut rope replacements by ~30% over a season (informal maintenance log).

- Shipyard tugger: VFD + reducer + grooved drum reduced operator “feathering” time; fewer crossovers, calmer deck work.

Vendor comparison (my quick-take)

| Vendor | Core strength | Customization | Price band (≈) |

|---|---|---|---|

| LBS (China) | Grooved drums, high-volume, solid reducer pairing | High: groove pitch, coatings, flanges | $$ (project-dependent) |

| Thern | Industrial winches, clean documentation | Medium | $$$ |

| Ingersoll Rand | Heavy-duty portfolios (incl. air winches) | Medium | $$$–$$$$ |

Customization and feedback

Options I’d specify for a Electric Drum Winch: groove pitch tuned to rope diameter/lay, flange reinforcement, marine epoxy, drain holes, and encoded drum for load monitoring. Operators often report quieter spooling and fewer rope bird-nests after switching to a properly grooved drum—nothing fancy, just consistent geometry.

Compliance cheat sheet

Specify to ASME B30.7 (winches), ISO 4308-1 (rope selection), DNV-ST-0377 (marine lifting), CE Machinery Directive. For drive enclosures, mind IEC 60529 (IP rating). Ask for proof-load certificates and NDT reports with delivery. I guess it sounds strict—but it saves headaches.

References

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025