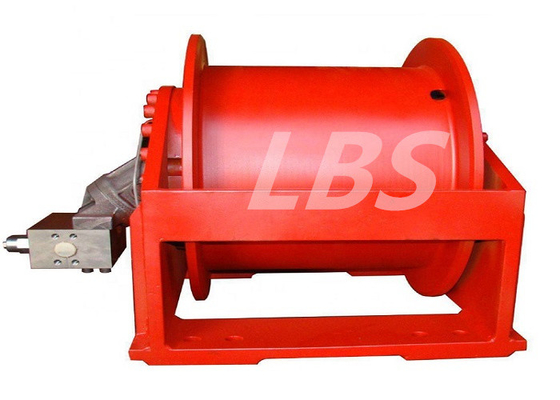

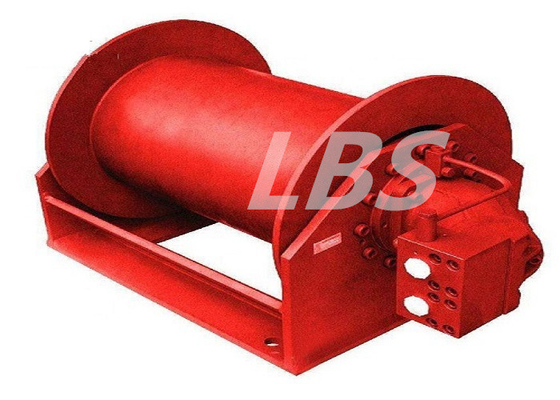

Efficient Drum Style Anchor Puller | Robust Marine Winch

Understanding the Modern drum style anchor puller: Industry Trends and Innovations

The maritime, offshore, and heavy industrial sectors constantly demand robust and reliable equipment to manage critical loads. Among these, the drum style anchor puller stands as a cornerstone for anchoring operations, mooring, and general heavy-duty pulling tasks. Recent industry trends emphasize enhanced safety, operational efficiency, and environmental sustainability. There's a significant shift towards more automated systems, improved material science for greater durability and corrosion resistance, and integrated monitoring capabilities for predictive maintenance. The demand for systems capable of operating in extreme conditions, from deep-sea environments to arctic regions, is also driving innovation in material selection and sealing technologies. Furthermore, the push for energy efficiency is leading to advancements in hydraulic and electric drive systems that minimize power consumption while maximizing torque output.

A key trend involves the integration of smart technologies, allowing operators to monitor line tension, speed, and position in real-time. This not only boosts operational safety but also extends the service life of both the equipment and the lines. The evolution of the drum style anchor puller is directly influenced by the need for compliance with increasingly stringent international maritime regulations and the growing complexity of offshore operations, necessitating the adoption of more sophisticated control systems and robust mechanical designs.

The Manufacturing Process of a High-Performance Drum Style Anchor Puller

The production of a high-quality drum style anchor puller involves a multi-stage, precision-engineered process designed to ensure durability, reliability, and optimal performance under extreme operational demands. Adherence to international standards like ISO 9001 for quality management and rigorous testing protocols are paramount.

Process Flow Overview:

1. Design & Engineering

Utilizing CAD/CAE software for structural integrity, load analysis, and mechanism design. Material selection based on target applications (e.g., high-grade alloy steels).

2. Material Sourcing & Preparation

Acquisition of certified raw materials, typically high-strength carbon steel, alloy steels (e.g., 42CrMoA), and marine-grade stainless steel for corrosion resistance.

3. Fabrication & Forming

- Casting: For large, intricate components like drum ends and gear housings, ensuring optimal material distribution.

- Forging: For critical load-bearing parts such as shafts and gears, enhancing grain structure and mechanical properties.

- Welding: Robotic and manual welding for structural assembly, adhering to AWS D1.1 standards, followed by non-destructive testing (NDT).

4. Precision Machining

- CNC Machining: For drums, shafts, gears, and bearing seats, ensuring tight tolerances for smooth operation and minimal wear.

- Surface Treatment: Grinding, polishing, and hard chrome plating for enhanced wear resistance and reduced friction.

5. Assembly & Integration

Installation of motors (hydraulic/electric), gearboxes, braking systems, control panels, and safety features. Lubrication and fluid checks.

6. Testing & Quality Assurance

- Load Testing: Static and dynamic load tests to 125% of rated capacity, verified by classification societies (e.g., ABS, DNV-GL).

- Functional Testing: Brake performance, speed control, emergency stop.

- Corrosion Resistance: Salt spray tests for painted/coated surfaces.

- Service Life: Designed for 20+ years with regular maintenance, exceeding industry averages.

Target industries for our robust drum style anchor puller solutions include petrochemical, metallurgy, water supply & drainage, marine & offshore, and construction. Advantages in typical application scenarios include significant energy saving through efficient hydraulic/electric drive systems, superior corrosion resistance due to marine-grade coatings and materials, and enhanced safety features meeting ANSI B30.7 standards for hoisting equipment.

Technical Specifications and Parameters of Advanced Anchor Pullers

Our range of anchor pullers, including specialized mechanical drum winch and double drum winch for high mast applications, are engineered for precise control and maximum power. Below are typical specifications that highlight the capabilities and robust design of these systems. These parameters are crucial for engineers and procurement specialists to ensure optimal equipment selection for specific operational requirements.

Typical Product Specifications: Hand Winch Drum Wrapping Drum Of Winch Split Barrel Double Drum Winch

| Parameter | Value/Description |

|---|---|

| Rated Pull (1st layer) | 50 kN - 300 kN (depending on model) |

| Wire Rope Capacity | Φ20mm x 500m to Φ60mm x 2000m |

| Working Speed | 0-15 m/min (variable speed control) |

| Braking System | Hydraulic-release, Spring-applied Disc Brake (fail-safe) |

| Motor Type | Electric (IP56/IP67 rated) or Hydraulic (closed-loop system) |

| Power Supply | 380V/50Hz/3Phase or customized |

| Control System | Local control, remote control (wired/wireless), PLC integration option |

| Material | High-strength alloy steel frame, marine-grade steel drum, stainless steel components |

| Surface Treatment | Marine-grade epoxy coating, anti-corrosion primer (C5-M rating) |

| Safety Features | Overload protection, emergency stop, limit switches, slack rope detection |

These specifications underline the capability of our drum style anchor puller systems to handle demanding tasks with precision and safety. The robust construction and advanced control options ensure reliable operation across a wide range of environmental conditions.

Application Scenarios and Technical Advantages

The versatility of the drum style anchor puller makes it indispensable across numerous heavy industries. Its design is specifically tailored to meet the rigorous demands of tasks involving substantial tensile forces and precision control.

Typical Application Scenarios:

- Marine & Offshore: Essential for ship mooring, anchor handling operations, towing, and maintaining the position of offshore platforms (e.g., oil rigs, wind turbine installation vessels).

- Port & Harbor: Used for managing cargo, adjusting vessel positions within docks, and heavy lifting operations.

- Construction: Employed in large-scale civil engineering projects for pulling heavy structures, pipeline laying, and bridge construction where precise tensioning is required.

- Mining: Hauling heavy equipment, ore wagons, or for shaft sinking operations, particularly with rugged mechanical drum winch configurations.

- Forestry: For skidding logs and other heavy material handling in challenging terrains.

- High Mast Lighting Systems: Specialized double drum winch for high mast applications ensure synchronized and controlled raising/lowering of lighting crowns for maintenance.

Technical Advantages:

- High Torque & Pulling Force: Engineered gear reductions and powerful drive systems deliver exceptional pulling capabilities, vital for large anchors and heavy loads.

- Precision Control: Advanced hydraulic or electric drive systems with variable speed control allow for smooth, precise handling, reducing shock loads and enhancing safety.

- Robust Construction: Built with high-strength steels and marine-grade components, ensuring longevity and resistance to harsh environments, including saltwater corrosion and extreme temperatures.

- Integrated Safety Features: Includes fail-safe braking systems, overload protection, emergency stops, and slack rope detection, minimizing operational risks.

- Efficiency: Modern designs incorporate energy-efficient motors and hydraulic pumps, reducing operational costs and environmental impact.

- Maintainability: Designed for ease of access to critical components for routine maintenance, contributing to lower downtime and extended service life.

Vendor Comparison and Customized Solutions

Selecting the right supplier for a drum style anchor puller is a critical decision that impacts long-term operational efficiency and safety. While many manufacturers offer standard products, the ability to provide customized solutions, robust after-sales support, and proven reliability sets leading vendors apart.

Key Factors in Vendor Comparison:

| Feature/Service | Leading Vendor (e.g., LBS Winch) | Typical Standard Vendor |

|---|---|---|

| Customization Capability | Extensive (load, speed, drum configuration, control system, integration) | Limited (minor modifications to standard models) |

| Certification & Standards | ISO 9001, CE, Class Society Approvals (ABS, DNV-GL, LR) | Basic CE compliance, may lack class society certification |

| Material Quality | Certified high-strength alloy steels, marine-grade components | Standard industrial steels, may not be optimized for marine environments |

| After-sales Support | Global service network, 24/7 technical support, spare parts availability | Regional support, limited spare parts, slower response times |

| Warranty Period | Extended 18-24 month warranty (depending on components) | Standard 12-month warranty |

| Technology & Innovation | Advanced PLC control, remote diagnostics, energy efficiency focus | Basic electrical/hydraulic controls, less focus on smart features |

Customized Solutions:

Recognizing that no two projects are identical, we specialize in providing tailored drum style anchor puller systems. This includes:

- Load Capacity & Speed: Custom-engineered to precise pulling force and line speed requirements.

- Drum Configuration: Single, double, or multiple drums; split barrel designs; grooved drums for optimal rope lay and extended wire rope life.

- Drive System: Selection between electric, hydraulic, or even pneumatic drives based on available power sources and environmental considerations.

- Control Systems: Integration with vessel management systems (VMS), human-machine interfaces (HMI), data logging, and customized automation sequences.

- Environmental Adaptations: Special coatings for corrosive marine environments, explosion-proof components for hazardous areas (ATEX compliant), or low-temperature packages for arctic operations.

- Footprint & Integration: Designed to fit specific deck layouts or machinery spaces, with consideration for weight distribution and interfacing with existing infrastructure.

Application Case Studies & Customer Experience

Our commitment to engineering excellence is best demonstrated through real-world applications and the feedback from our valued clients. We have successfully deployed various drum style anchor puller systems in challenging environments globally.

Case Study 1: Offshore Wind Farm Installation

A major European offshore contractor required a high-capacity anchor puller for positioning a jack-up vessel during offshore wind turbine installation. The challenge was to provide precise control under dynamic weather conditions and ensure reliable operation in a corrosive saltwater environment. We supplied a custom 200 kN hydraulic drum style anchor puller with a grooved drum for optimal wire rope management and an integrated PLC control system for synchronized operation with the vessel's dynamic positioning system.

- Outcome: The system provided unparalleled control, reducing vessel positioning time by 15% and significantly enhancing safety during critical lift operations. The marine-grade coatings ensured excellent corrosion resistance, leading to minimal maintenance during the 2-year project phase.

- Customer Feedback: "The reliability and precision of their anchor puller were instrumental in keeping our project on schedule and within budget. The technical support throughout installation and commissioning was exceptional." - Project Manager, Offshore Wind Solutions Ltd.

Case Study 2: River Dredging and Pipeline Laying

For an infrastructure project involving river dredging and the laying of large-diameter pipelines, a client needed a robust mechanical drum winch system to manage anchor lines for their dredge and supply barges. The environment presented challenges with fluctuating water levels and abrasive riverbed conditions. We delivered a series of 80 kN mechanical drum winch units, specifically designed with enhanced gear protection and easy-to-replace wear parts.

- Outcome: The winches performed flawlessly, enduring continuous heavy-duty cycles. Their mechanical robustness ensured consistent pulling power without the complexities of hydraulic systems, ideal for remote operational sites. The system's maintainability proved cost-effective over the project's duration.

- Customer Feedback: "We appreciate the ruggedness and straightforward operation of these winches. They’ve been workhorses for us, handling significant loads without issue, even in challenging river conditions." - Operations Director, AquaFlow Engineering.

Trustworthiness: FAQ, Lead Time, Warranty & Support

Frequently Asked Questions (FAQ):

Q: What is the typical lead time for a custom drum style anchor puller?

A: For standard models, lead time is typically 8-12 weeks. Custom-engineered solutions may range from 16-24 weeks, depending on complexity and material availability. Expedited options are available upon request.

Q: What warranty is provided with your anchor pullers?

A: We offer a comprehensive 18-month warranty from the date of delivery or 12 months after commissioning (whichever comes first) on all mechanical and structural components, and 12 months on electrical and hydraulic parts, covering manufacturing defects. Extended warranty options are available.

Q: Can your systems be integrated with existing vessel or plant control systems?

A: Absolutely. Our drum style anchor puller control systems are designed for seamless integration with various third-party PLC/SCADA systems and vessel management systems using industry-standard communication protocols (e.g., Modbus, Ethernet/IP, Profibus).

Q: How do you ensure product reliability and compliance with international standards?

A: Our manufacturing processes adhere strictly to ISO 9001 quality management standards. All products undergo rigorous testing, including full load tests witnessed by classification societies (e.g., ABS, DNV-GL, Lloyd's Register) upon client request, ensuring compliance with relevant international standards such as CE, IMO, and Classification Society rules.

Lead Time & Fulfillment:

Our streamlined production process, combined with robust supply chain management, allows us to offer competitive lead times. We maintain transparent communication throughout the order fulfillment process, providing regular updates from design confirmation to factory acceptance testing (FAT) and final shipment. Global logistics partnerships ensure efficient and reliable delivery to your project site.

Warranty Commitments:

Our comprehensive warranty reflects our confidence in the quality and durability of our products. Each drum style anchor puller is backed by a robust warranty, with detailed terms provided at the time of quotation. This commitment provides peace of mind and safeguards your investment.

Customer Support & After-Sales Service:

We pride ourselves on exceptional customer support. Our dedicated after-sales team offers:

- Technical Assistance: 24/7 remote technical support and troubleshooting.

- On-site Service: Skilled technicians available for installation supervision, commissioning, and periodic maintenance globally.

- Spare Parts Management: Comprehensive inventory of critical spare parts for rapid dispatch, minimizing downtime.

- Training Programs: Operator and maintenance staff training to ensure safe and efficient operation of the equipment.

References

- Marine Technology Society Journal. (2023). Advances in Offshore Mooring and Anchoring Systems. Vol. 57, No. 3, pp. 45-58.

- Journal of Ocean Engineering and Science. (2022). Material Selection for Marine Winch Components: A Durability Study. Vol. 6, No. 4, pp. 210-225.

- International Organization for Standardization (ISO). (2020). ISO 9001:2015 - Quality management systems.

- American Society of Mechanical Engineers (ASME). (2018). ASME B30.7 - Winches.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025