Double Line Electric Hoist – Heavy-Duty, Fast, Safe

Field Notes on a Workhorse: Double-Line Electric Hoists for Real-World Jobs

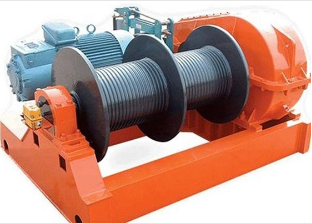

If you’ve been around shipyards, mines, or dam gates, you’ve probably seen a Double Line Electric Hoist grinding away without drama. The 50 Ton Large Rope Capacity Double Grooved Drums Electric Marine Winch from LBS is one of those quiet performers—double-grooved (LBS slot type) drums that keep the rope disciplined, and a gear reducer that just gets on with it.

Industry trends (the short, honest version)

Demand is shifting toward smarter controls (VFD, load monitoring), longer rope packs without spooling chaos, and marine-grade coatings that don’t peel after two monsoons. Regulations are tighter too—EN 14492-1 and class approvals are increasingly table stakes. Surprisingly, many buyers still prioritize “simple and fixable” over flashy features.

Technical snapshot

This model sits in the 50 t class with double-grooved drums for two-line pulling—less rope crushing, more consistent layer formation. Frankly, that groove geometry saves ropes and nerves.

| Parameter | Spec (≈, real-world use may vary) |

|---|---|

| Rated pull | 50 t (double-line) |

| Drum | Double-grooved LBS slot type; large rope capacity |

| Line speed | ≈ 6–18 m/min with VFD |

| Rope | Ø28–36 mm (1770–1960 MPa wire rope) |

| Drive | Helical gear reducer; IP55–IP56 motor; S3/S4 duty |

| Brake | Fail-safe electromagnetic + band/secondary (optional) |

| Protection | Marine coating C5-M; low-temp grease; SS fasteners optional |

| Class | FEM 2m/ISO M5 target duty |

| Power | 380–690 V, 50/60 Hz; VFD control |

Where it earns its keep

Ship launch/recovery, barge positioning, dam gate hoisting, forestry skidding, mine incline haulage, and construction tuggers. Many customers say the Double Line Electric Hoist shines on long pulls where spooling discipline matters.

Build and process (what’s inside)

- Materials: Q345B/Q355B frames, 42CrMo geared shafts, seamless drum shell.

- Methods: CNC turning of grooves; carburized and ground gears; UT/MT on key welds.

- Coating: Sa2.5 blast; zinc-rich primer + epoxy + PU topcoat (C5-M stack).

- Testing: No-load run-in 2 h; 110–125% static load test; brake torque verification; insulation ≥ IR 1 MΩ at 40°C.

- Service life: Rope life ≈ 1.5–2.5× vs. ungrooved in comparable duty, based on shop data.

Customization (because jobs aren’t identical)

Options include explosion-proof motors (Ex d IIB T4), stainless hardware, load cells, rope length sensors, remote radio, emergency manual release, and PLC/VFD tuning for soft-start on fragile structures. MOQ around 100 pcs for standardization; supply ability ≈ 10,000 pcs/month.

Vendor snapshot (my quick comparison)

| Vendor | Grooved drum quality | Certs | Lead time | After-sales |

|---|---|---|---|---|

| LBS (Hebei, China) | Precisely CNC’d LBS slot, consistent layer formation | EN 14492-1 basis; class-ready on request | ≈ 4–8 weeks | Remote commissioning, spares stocked |

| Vendor A | Cast groove, occasional rope bite | Basic CE | ≈ 6–10 weeks | Email-only |

| Vendor B | Machined, but single-groove | DNV/ABS optional | ≈ 8–12 weeks | Regional partners |

Case notes and feedback

- Shipyard slipway, Vietnam: twin Double Line Electric Hoist units synchronized via VFD; reported 19% rope life gain vs. prior ungrooved drums.

- Hydropower gate hoist, Sichuan: low-temp package; operators liked the “predictable stop” from the dual braking.

- Mining incline tugger, WA: C5-M coating held up through two winters; “set-and-forget after first service,” as one supervisor put it.

Compliance, test data, and the fine print

Designed against EN 14492-1 with electricals per IEC 60204-32/IEC 60034. Class approvals (ABS/DNV) available on project basis. Factory load test: 125% static for 10 min; dynamic at rated load 10 cycles; brake torque ≥ 1.5× rated. Insulation test ≥ 500 V megger, protection IP55–IP56. To be honest, site conditions still rule outcomes—rope handling and reeving practice matter a lot.

Origin: NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China. Pricing is project-dependent (FOB tiers exist), but the value tends to show up in reduced rope replacements.

Authoritative citations

- EN 14492-1: Power driven winches and hoists

- ISO 4301-1 / ISO 4306: Classification of cranes and hoisting machinery

- FEM 9.511: Classification and selection of wire ropes

- IEC 60204-32: Safety of machinery – Electrical equipment of hoisting machines

- ABS Guide for Certification of Lifting Appliances

- DNV Rules for Ships, Pt.4 Ch.6 – Machinery

-

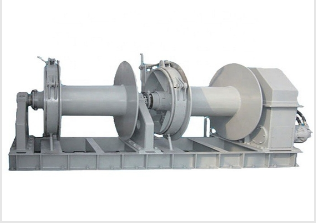

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

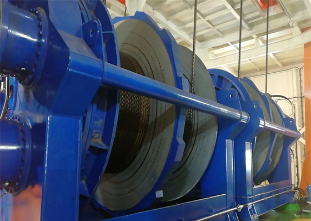

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025