Double Drum Winches: Synchronized Control & 120V Options?

Field notes on double drum winches: what’s real, what’s hype

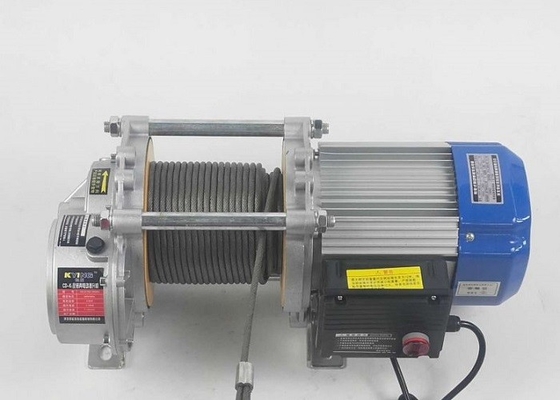

If you spend time around rigs and piling yards, you’ll notice the quieter hum of 12–48V electrics edging out old hydraulics. To be honest, I like it—less mess, easier diagnostics. The Electric Winch Drum Winch 12V Transfer Gear unit coming out of NO.688 Zhongshan Road, Qiaoxi district, Shijiazhuang, Hebei, China, feels like a workman’s tool first and a spec sheet second. And that’s rare lately.

Industry trends I’m seeing

- Electrification at low voltage (12/24V) for service rigs and skids—safer, simpler, easier permitting.

- LEBUS-grooved drums for rope life; fewer crushes and better spooling when operators are, well, human.

- Integrated torque and line-pull logging—maintenance teams love the data, even if they grumble at first.

- Hybrid lubrication: forced + splash in the gearbox for real-world duty cycles.

Product snapshot (real-world, not brochure-speak)

| Model | Electric Winch Drum Winch 12V Transfer Gear (Double Drum) |

| Drive | 12V DC electric, transfer gear reduction |

| Line pull (per drum) | ≈ 2–8 t (application-dependent; real-world use may vary) |

| Line speed | ≈ 8–20 m/min variable |

| Drum | Double drum, optional LEBUS groove or smooth |

| Materials | Cast shell housing; forged critical components |

| Lubrication | Forced + splash (power end) |

| Protection | IP54–IP65 options |

| Certs | Factory ISO 9001; CE on request; ATEX/IECEx optional |

| Price & MOQ | FOB ≈ US $0.5–9,999 / piece; MOQ: 100 pcs; Supply ≈ 10,000 pcs/month |

Note: this unit is often paired on rigs that also run NB-series mud pumps. Some literature even borrows language from those pumps—long stroke, better suction buffering, etc.—because the packages are integrated on petroleum drilling tools. Different component, same worksite.

Process flow, testing, and lifespan

- Materials: cast shell, forged shafts/pins; heat-treated gears; rope-friendly drum grooves.

- Methods: CNC machining, gear grinding, shot-peening on load paths, epoxy-polyurethane coating.

- Testing: proof load at 1.25× SWL (per EN 14492-1), static brake test 1.5×, insulation ≥ 10 MΩ, IP verification to IEC 60529.

- Typical service life: 8–12 years with rope changes at 1,500–3,000 hours (depending on spooling discipline).

- Industries: oilfield drilling/workover, piling, mining maintenance, marine deck handling (inshore), utilities.

Where double drum winches shine

Rig floors: one drum for hoist, the other for tool handling. In piling, one drum lifts, the other stages the hammer. Many customers say the redundancy is worth the small weight penalty. I guess it’s the “sleep-better” option.

Two quick case notes

- Desert workover rig (MENA): double drum winches with forced+splash lube cut gearbox temps by ≈12°C, extending oil change intervals from 500 to 800 hours.

- Piling contractor (SEA): swapping to LEBUS grooves reduced rope scrapping by ~28% over six months—surprisingly big savings.

Vendor snapshot (my practical take)

| Vendor | Core strength | Lead time | Certs | Notes |

| LBS (Hebei) | LEBUS drums, oilfield packages | ≈ 4–8 weeks | ISO 9001; CE optional | Strong after-sales on rigs |

| Regional A | Marine coatings | ≈ 6–10 weeks | DNV shop approvals | Pricier, great for deck gear |

| Import B | Low cost | Stock/spotty | Basic CE | Check gearbox spec closely |

Customization: drum groove patterns, gear ratios, brake configs (fail-safe spring-applied), stainless fasteners, and hazardous-area electrics (ask for ATEX/IECEx). Origin matters for spares—here it’s Hebei, with decent logistics.

Final thought: double drum winches aren’t glamorous, but when the brake test passes first try and the rope spools tight on a windy pad, the crew notices. That’s the kind of “spec” that doesn’t fit in a brochure—yet it’s what keeps the job on schedule.

References

- EN 14492-1: Power driven winches and hoists (Design and safety).

- DNV-ST-0378: Offshore and platform lifting appliances.

- ISO 4301-1: Classification of cranes and lifting mechanisms.

- IEC 60529: Degrees of protection (IP Code).

- API Spec 8C: Drilling and production hoisting equipment.

-

Double Drum Hydraulic Winch – Durable, Efficient Load Handling SolutionsNewsNov.25,2025

-

Hydraulic Drum Winches: Powering Heavy Lifting with Precision and DurabilityNewsNov.24,2025

-

Hydraulic Driven Winch – Reliable Heavy Lifting Solutions for Industry & ReliefNewsNov.24,2025

-

Hydraulic Crane Winch – Powerful & Precise Heavy Lifting Solutions | LBS WinchNewsNov.23,2025

-

Electric Over Hydraulic Winch: Efficient, Durable Lifting Solutions for Modern IndustryNewsNov.23,2025

-

Hydraulic Logging Winch Guide | Global Applications & InnovationsNewsNov.22,2025